Gastroscopic assembly pipe

A technology of gastroscope and cannula, which is applied in gastroscope, esophagoscope, medical science, etc. It can solve the problems of long time suffering for patients, unreasonable tube design, and long time-consuming diagnosis, so as to shorten operation time and improve diagnostic ability and diagnostic efficiency, the effect of protecting the probe wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

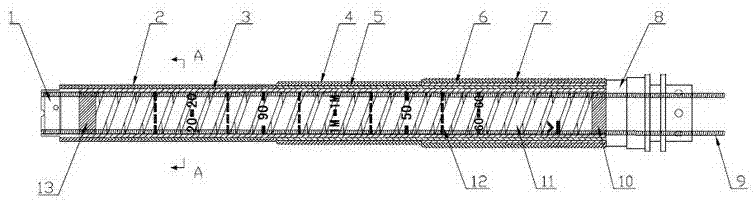

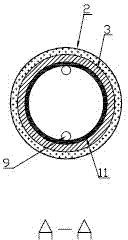

[0011] Such as figure 1 As shown, the present invention includes a casing, a first stainless steel mesh pipe 3 , a second stainless steel mesh pipe 5 , a third stainless steel mesh pipe 6 , a spring pipe 11 , an adapter ring 1 and an equipment connector 8 .

[0012] The first stainless steel woven mesh pipe 3 is set on the spring tube 11 , the casing is set on the first stainless steel woven mesh pipe 3 , the front section of the casing pipe is connected with the adapter ring 1 , and the end is connected with the equipment connector 8 .

[0013] The casing has a stepped structure and is divided into a front section 2, a middle section 4 and an end section 7. The outer diameter of the middle section 4 of the casing is larger than that of the front section 2 of the casing, and the outer diameter of the last section 7 of the casing is larger than that of the middle section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com