Method for producing seamless tube

A manufacturing method and technology of seamless steel pipe, applied in the direction of metal rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

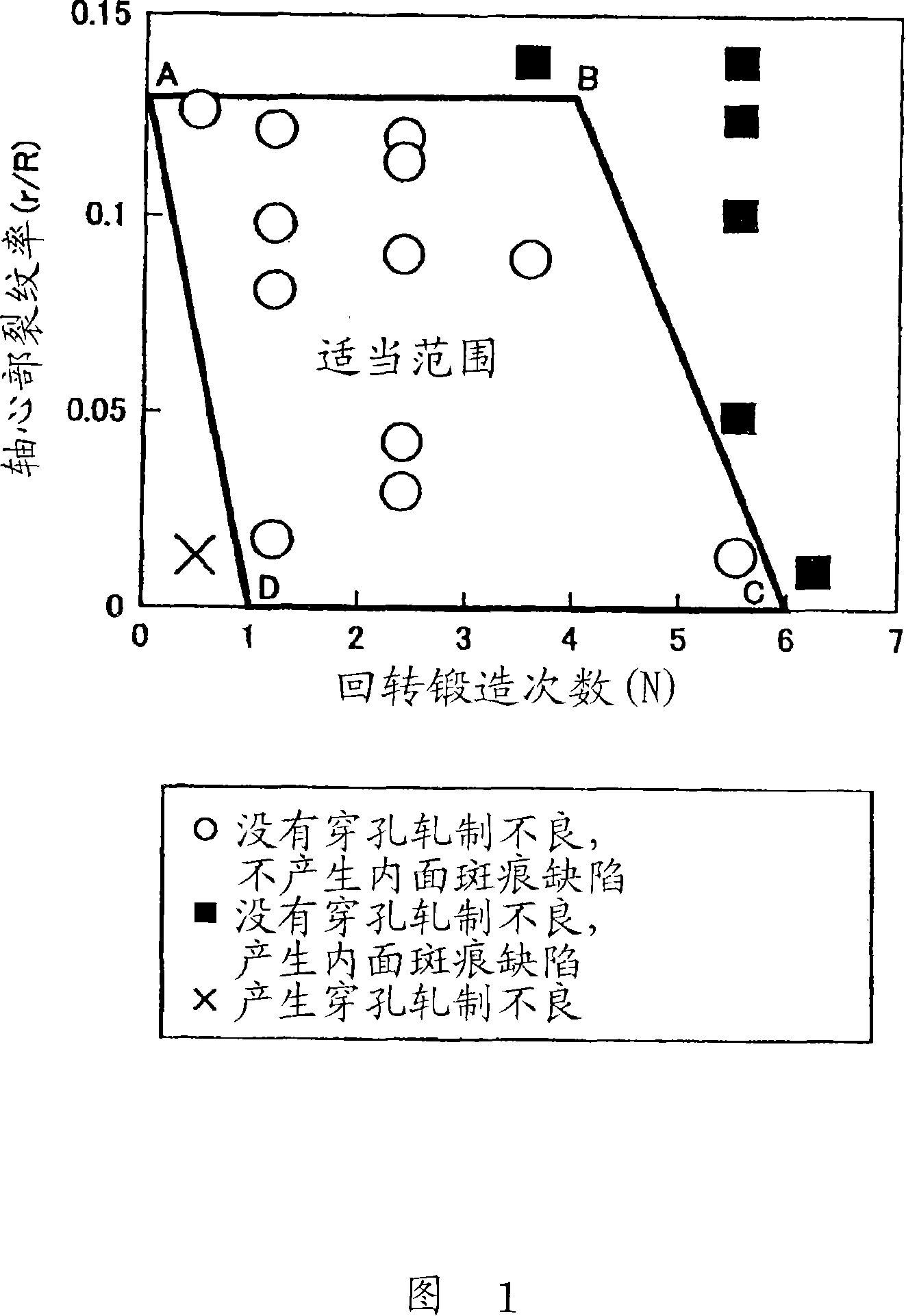

[0031] As described above, the method of the present invention is a method for manufacturing a seamless steel pipe by combining the ratio of cracks in the axial center (r / R) obtained from the diameter of the billet and the length of the crack in the axial center of the billet, and the ratio of cracks in the billet from The number N of rotary forgings received during the period from contacting the roll to reaching the piercing plug is adjusted within a range that simultaneously satisfies the relationships expressed by the above-mentioned formulas (1) to (3). Next, the method for manufacturing the seamless steel pipe of the present invention will be described in more detail.

[0032] 1) Crack rate in the axial center of the billet

[0033] As described above, the axial center crack ratio of the steel slab is defined by the value (r / R) obtained by dividing the axial center crack length (r) of the steel slab by the diameter (R) of the steel slab. Here, when there are a plurality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap