Whole wallboard assembled house prefabricated by reinforced concrete constitution

A technology of reinforced concrete and wall panels, which is applied in the direction of residential construction, etc., and can solve problems such as excessive engineering waste, long construction period, and backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

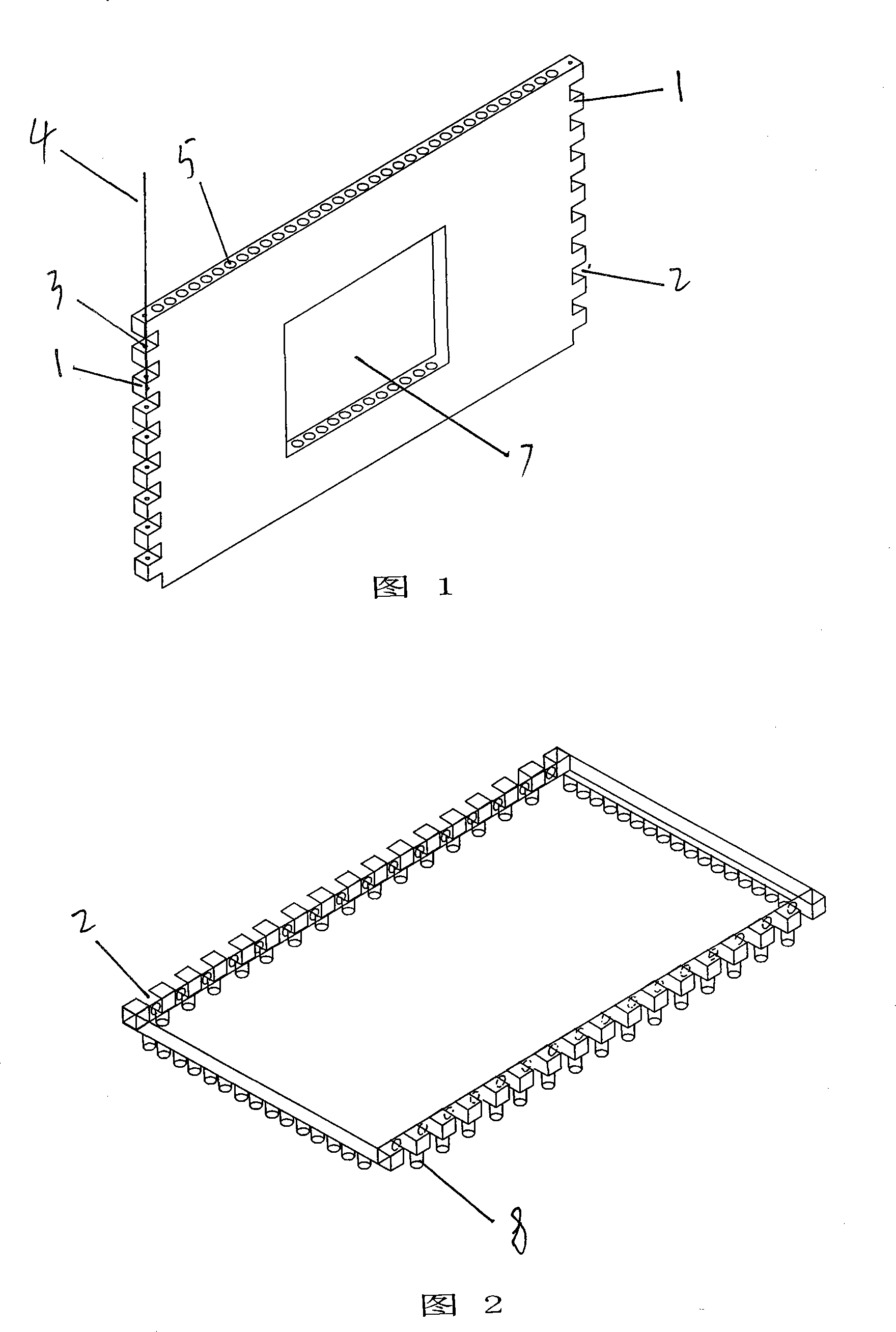

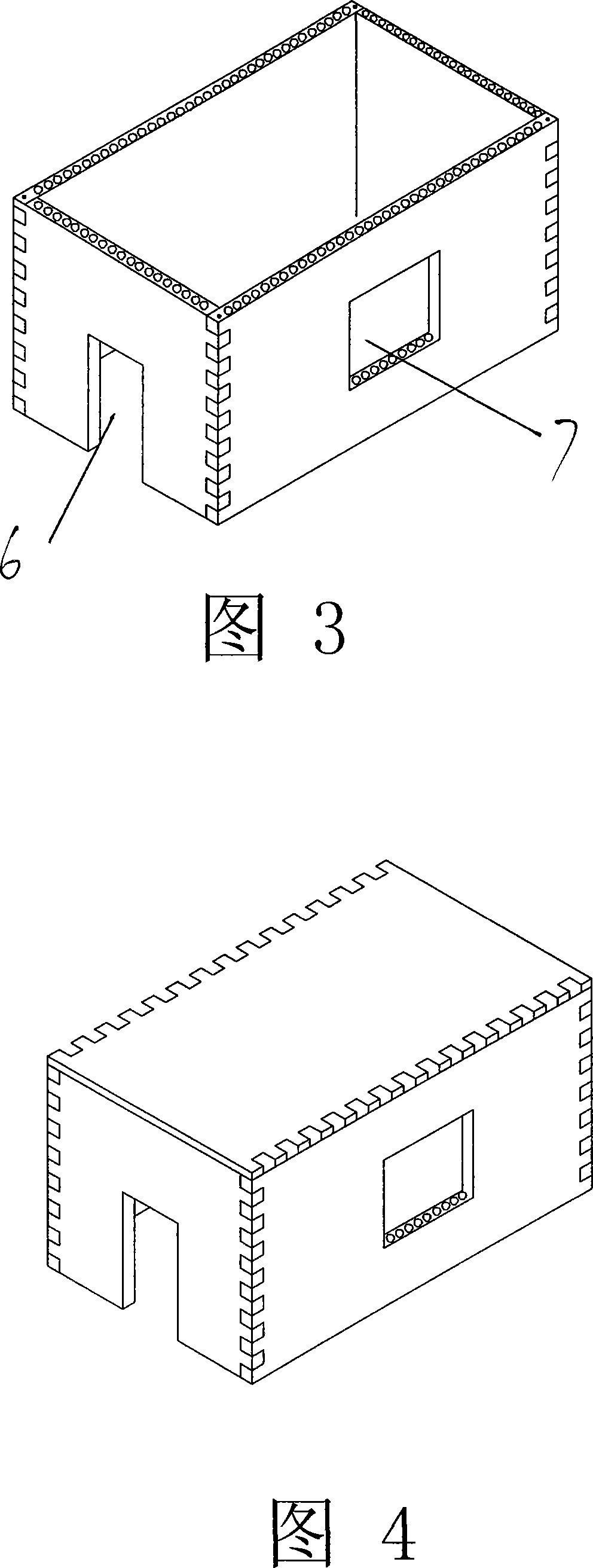

[0011] Below in conjunction with accompanying drawing and embodiment the utility model is described further.

[0012] Pull the prefabricated wall panels from the prefabrication factory to the building site, hoist the front cornice wall of the house to the corresponding position with a crane, and then lift the left grid wall to the corresponding position, so that the left plug 1 of the front cornice wall and the left grid The sockets 2 on the front of the wall match each other, so that the lock cores 3 on all the plugs are facing each other, and then the equipped lock cylinder 4 penetrates all the lock cores 3 from top to bottom, so that all the plugs 1 on the two wall boards are fixed together. The cornice wall and the left fence wall are fixed together, and then the right fence wall is hung to the right side of the cornice wall and connected in the same way.

[0013] Then connect the rear ends of the left and right grid walls of the back eaves wall in the same way. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com