Apparatus on a drafting system of a spinning room machine, for weighting drafting system rollers

一种牵伸装置、设备的技术,应用在牵伸设备、纺纱机、流体压力致动装置等方向,能够解决不可能检测活塞行程等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

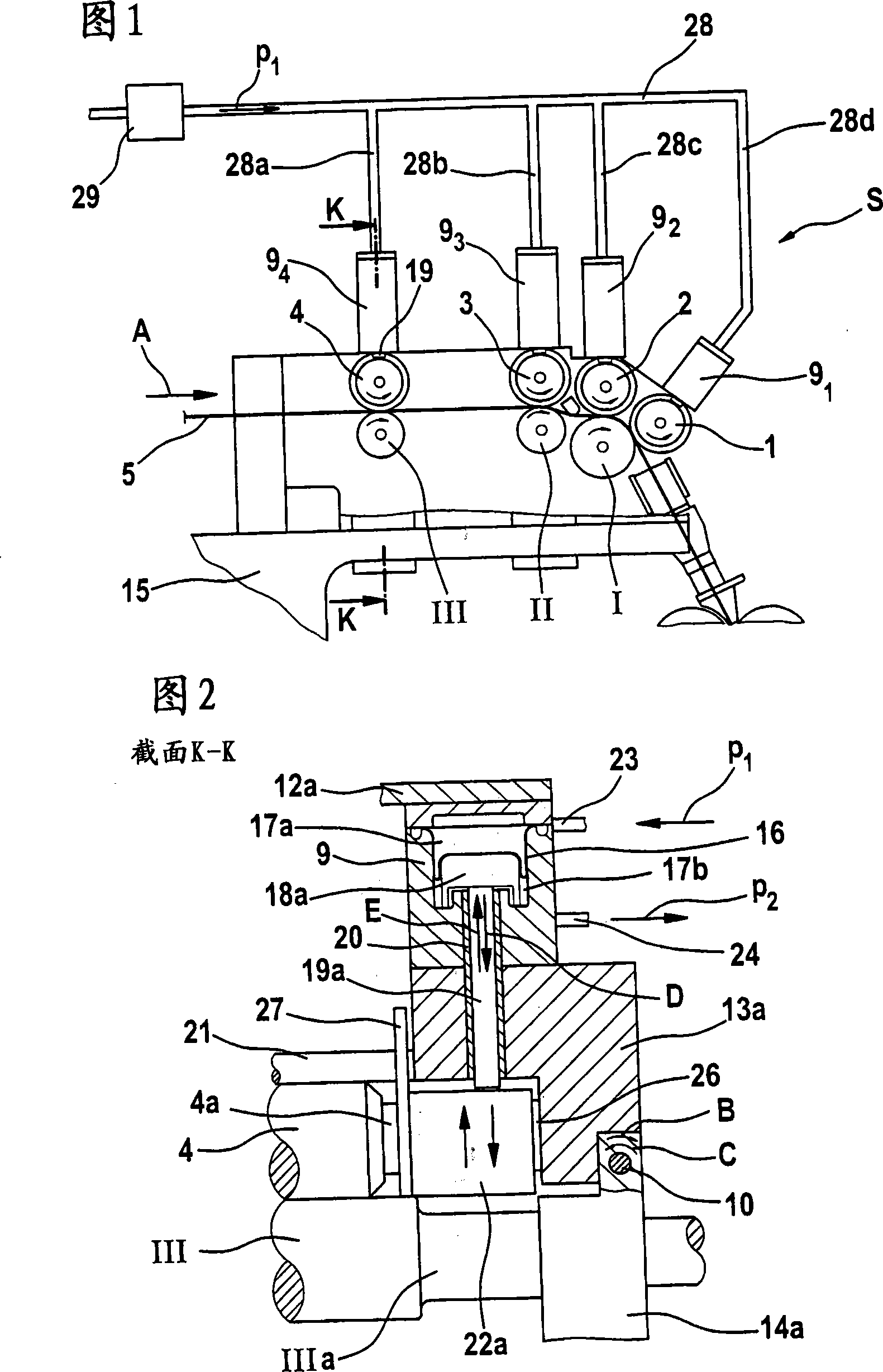

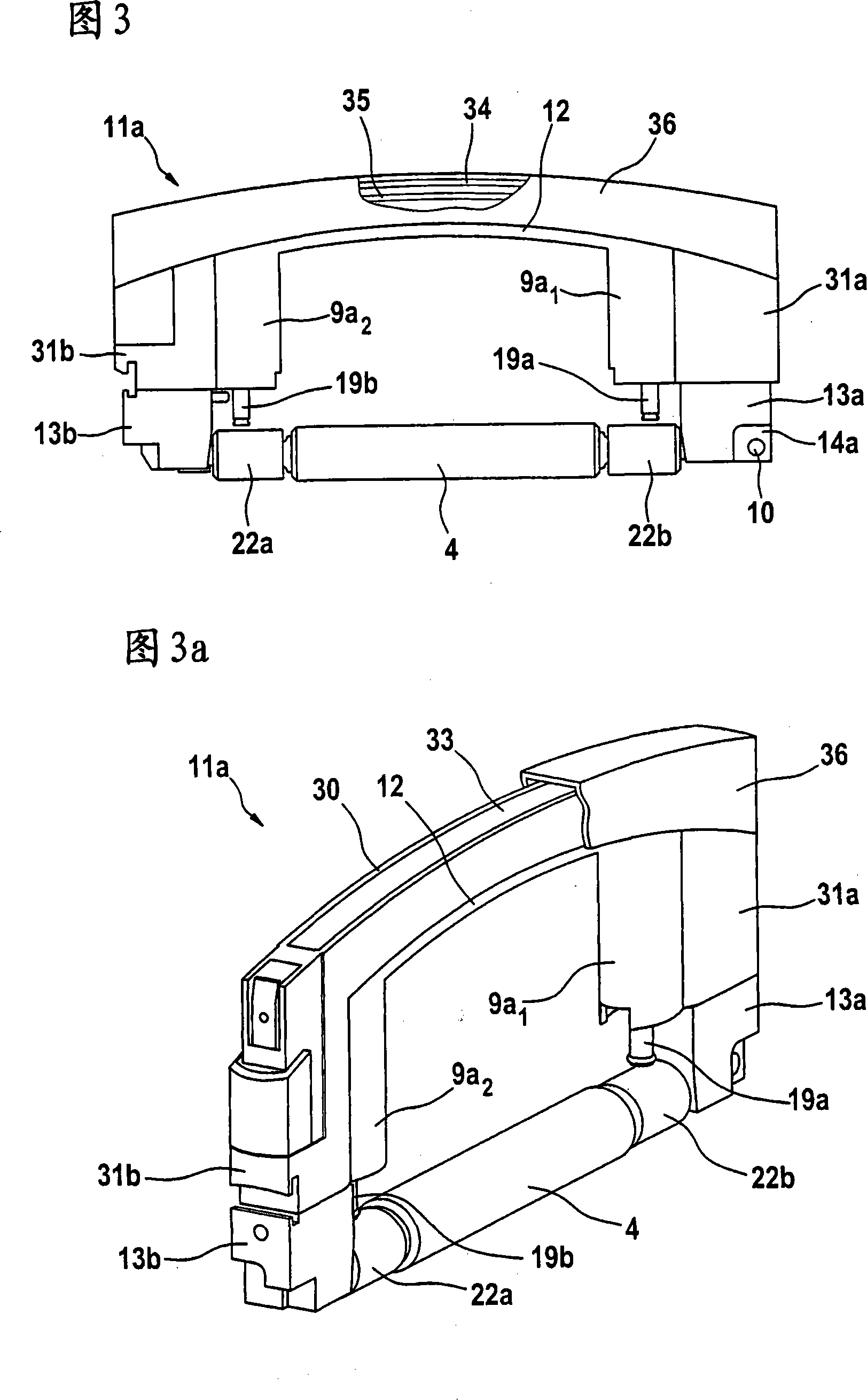

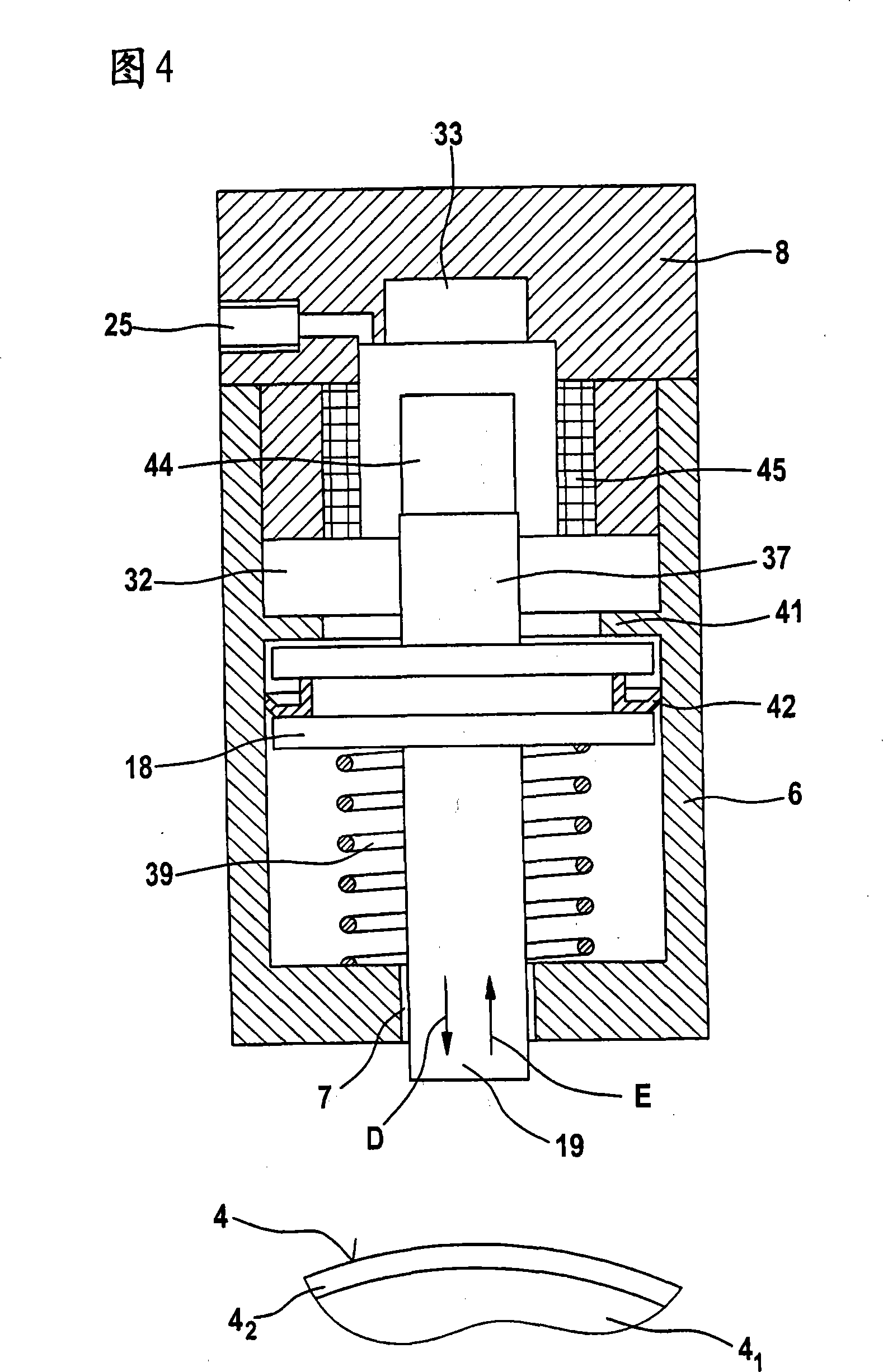

[0016] Figure 1 shows a drafting unit S such as a Trützschler Strecke TC03 draw frame. The drafting device S is constructed as a 4-up and 3-down drafting device, that is to say, it includes three lower rollers I, II, III (I draws out the lower roller, II middle lower roller, III feeds the lower roller) and Four upper rollers 1, 2, 3, 4. In the drafting device S, the drafting of the fiber bundle 5 with a plurality of slivers is performed. The drafting operation is composed of the pre-drawing operation and the main drafting operation. Roller pairs 4 / III and 3 / II form the pre-drafting zone, while roller pairs 3 / II and 1, 2 / I form the main drafting zone. The take-off lower roller I is driven by a main motor (not shown) to measure the conveying speed. Feed lower roller III and intermediate lower roller II are driven by adjustment motors (not shown). The upper rollers 1-4 pass through the pressing elements 9 in the pressing arms 11a-11d 1 ~9 4 (Loading device), pressurizing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com