Shower cabinet sliding glass door

A push-pull, shower room technology, applied in the direction of door leaf, wing leaf arrangement, condensate water discharge, etc., can solve the problems of low manufacturing level, time-consuming and laborious glass door installation, poor manufacturing, etc., to improve the sealing performance and maintenance. And the effect of convenient replacement and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

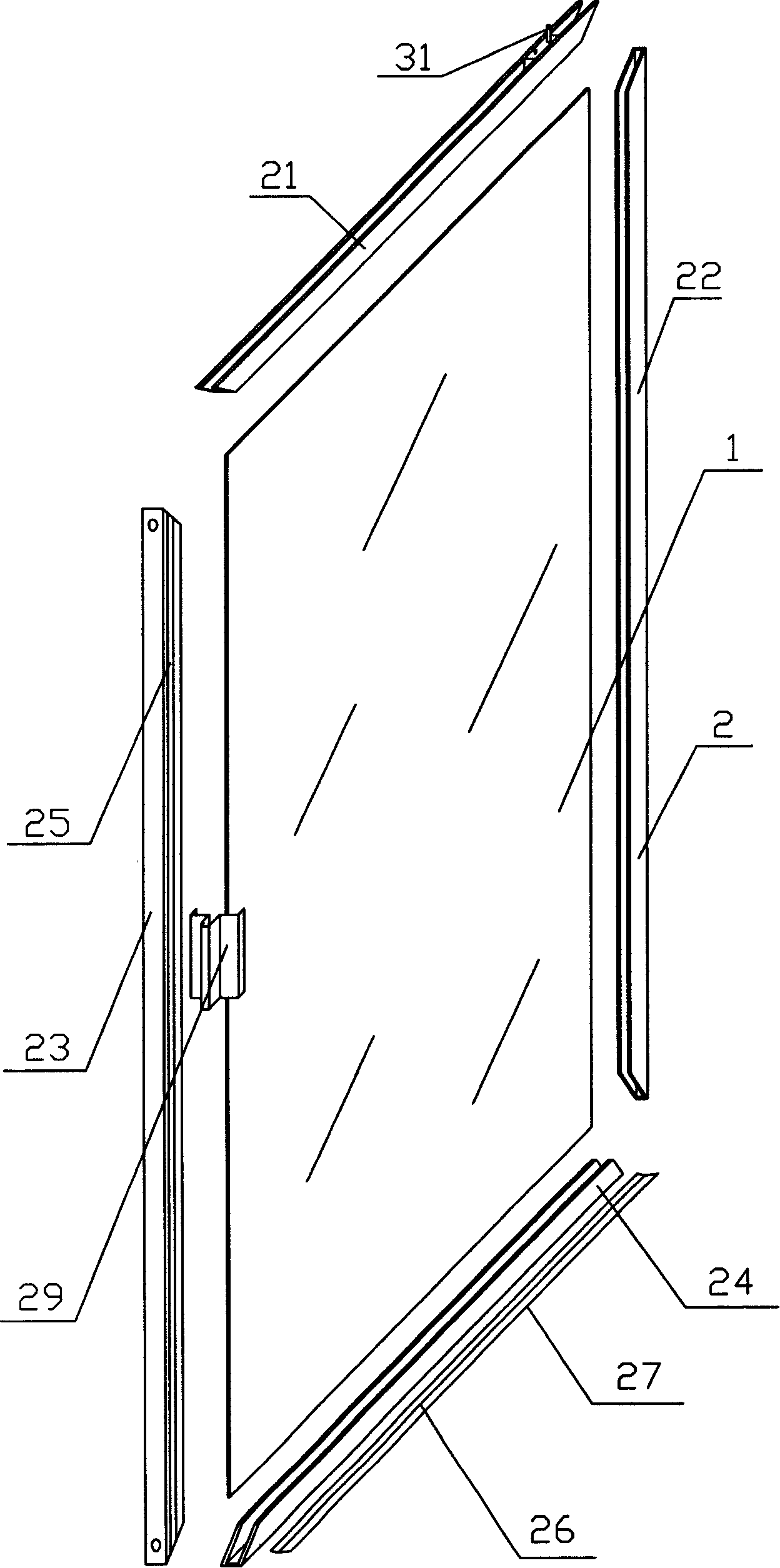

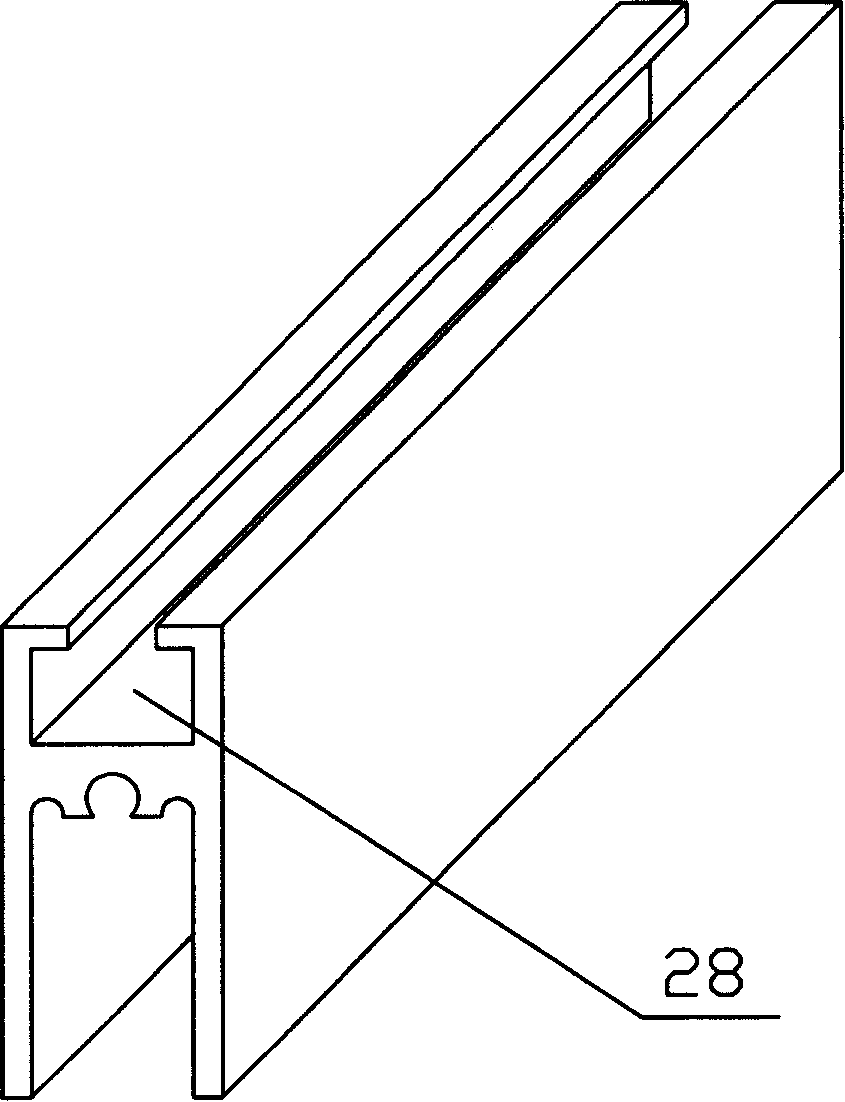

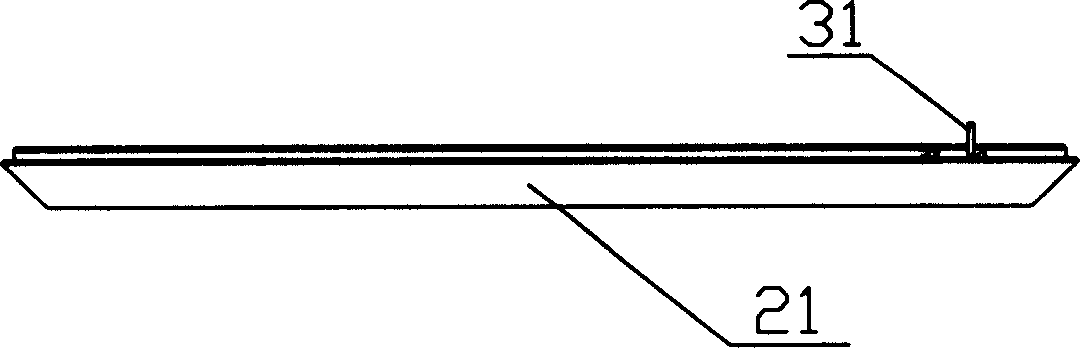

[0024] Such as figure 1 As shown, the push-pull glass door for a shower room of the present invention comprises a door leaf and a door frame, and the main body of the door leaf has a rectangular toughened glass 1 with wrapping around it, and a sealing ring is embedded between the wrapping 2 and the toughened glass 1 (in the figure Not shown), the inner side of the switch edge wrapping 23 is provided with a sealing strip 25, Figure 5 As shown, there is a sealing strip 55 corresponding to the sealing strip 25 on the outside of the switch side door frame, figure 1 Among them, the water retaining plate 26 is horizontally fixed on the inner side of the bottom edge wrapping 24, and the water retaining plate (not shown in the figure) is arranged axially on the inside of the rotating side door frame.

[0025] Among them, the door leaf is made of imported thin high-strength tempered glass (thickness is about 3 mm), and it is made of special polished aluminum alloy profiles; the overa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com