Method for producing high water absorption resin

A manufacturing method and water-absorbing technology, which is applied in the field of manufacturing water-absorbing resins, can solve problems such as reducing production efficiency, achieve the effects of improving product quality, stabilizing the polymerization reaction process, and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

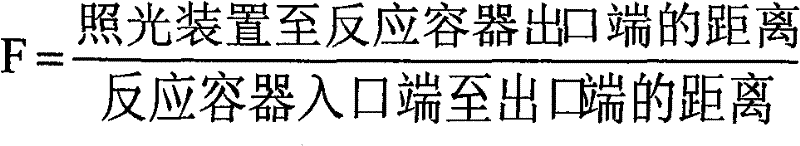

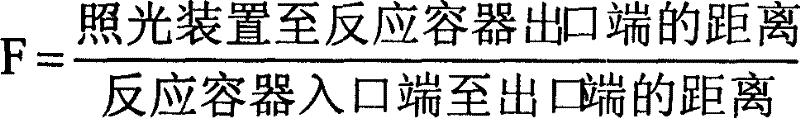

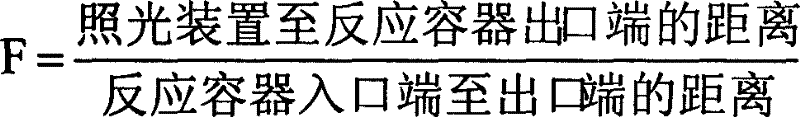

Image

Examples

Embodiment 1

[0058] 1) Add 1984g of acrylic acid and 2685.3g of water into a 6000c.c nitrogen-substituted container; in addition, weigh 1528.6g of 49% sodium hydroxide aqueous solution, and slowly add the sodium hydroxide aqueous solution into the acrylic acid aqueous solution under ice-cooling Neutralization is carried out; at this time, an aqueous solution with an acid group-containing monomer concentration of 38.6 wt% is obtained, in which 68 mol% of acrylic acid is neutralized into sodium acrylate.

[0059] 2) Add the above-mentioned neutralized acid group-containing monomer aqueous solution and 0.1 g of potassium persulfate: sodium sulfite = 1: 1 (weight ratio) into a horizontal cylindrical prepolymerization reactor equipped with a jacket for mixing and prepolymerization reactions. The reaction temperature was 20° C., the reaction time was 60 minutes, and the viscosity of the obtained prepolymer was 100 cps.

[0060] 3) Add the viscous prepolymer and 9.98g N, N'-bis(2-propenyl)amine ...

Embodiment 2

[0065] Repeat Example 1, but N, N'-bis(2-propenyl)amine is reduced to 0.2 parts by weight for monomer addition. The rest is the same as in Example 1 to obtain a superabsorbent resin, the measured retention force is 29.87g / g, and the residual monomer is 42.6ppm.

Embodiment 3

[0067] Example 1 was repeated, but the degree of neutralization was increased to 75 mol%. The rest is the same as in Example 1 to obtain a superabsorbent resin, the measured retention force is 30.24g / g, and the residual monomer is 53.9ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com