Lining system and method thereof

A direction conversion, reverse direction technology used in the field of scribing systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] First, the concept of the present invention will be described.

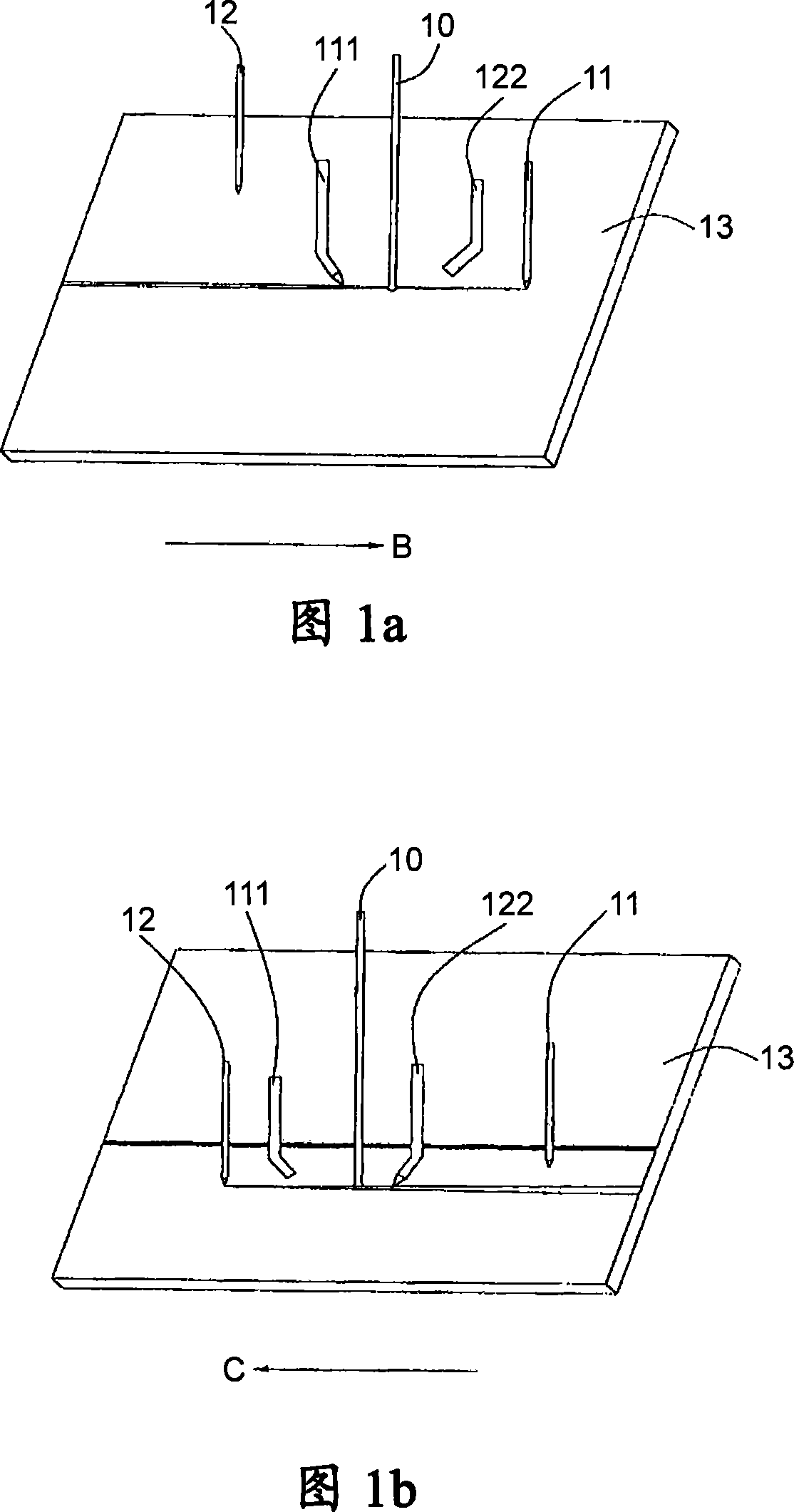

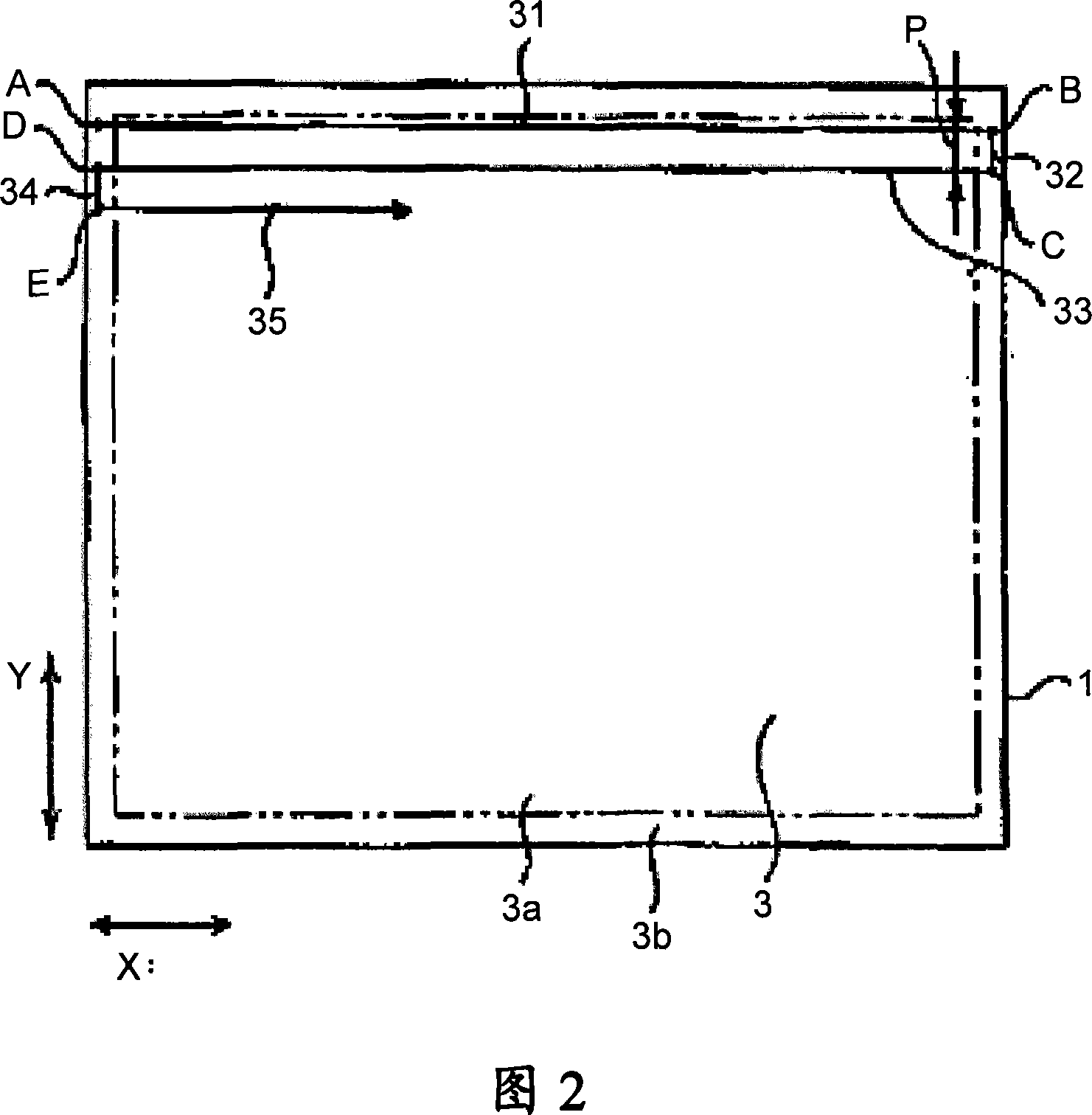

[0038] In the scribing system and method according to the present invention, a technique is provided in which the scribing process can be performed in the opposite direction without raising the wheel.

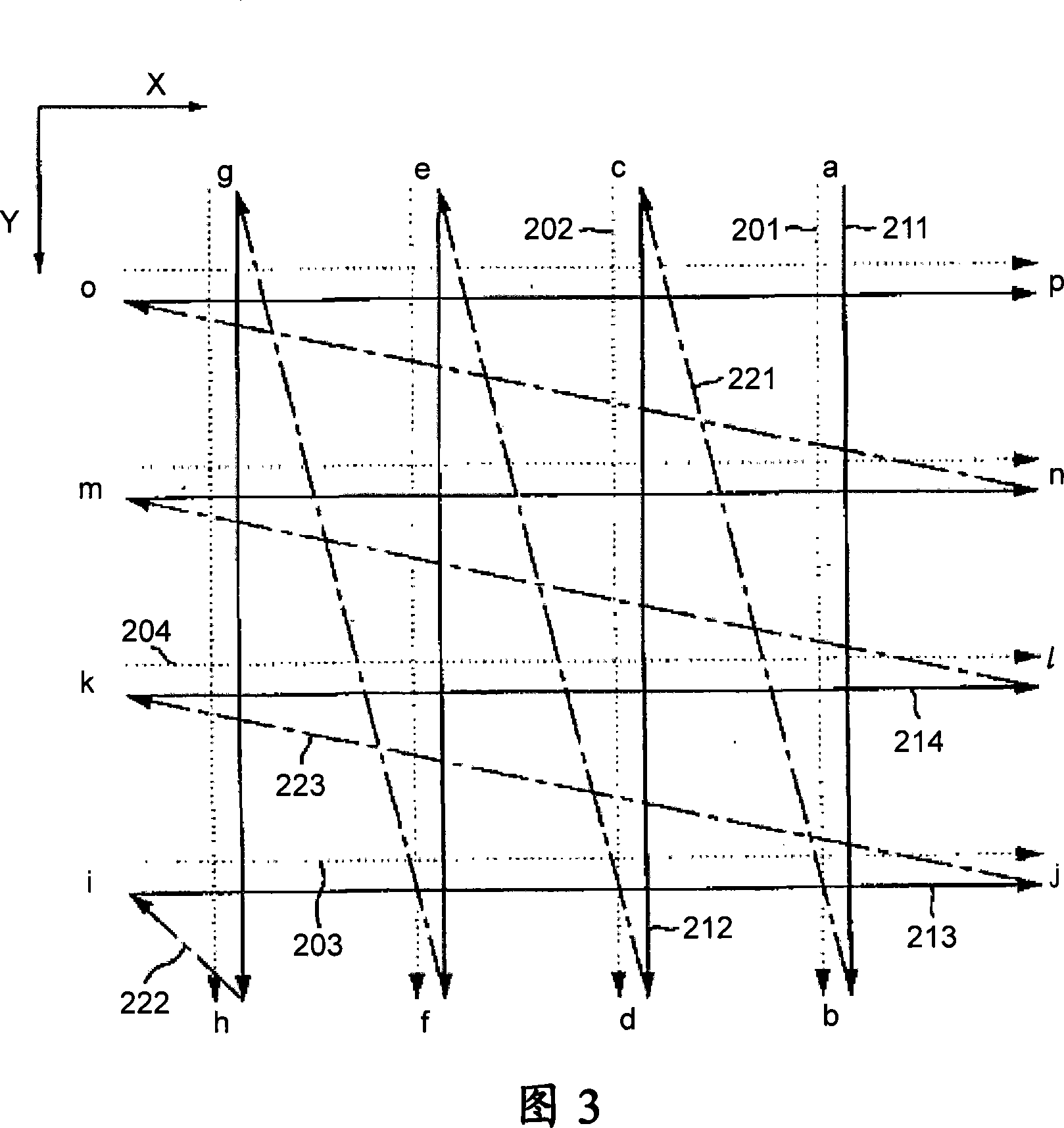

[0039] That is, in the scribe line forming method shown in FIG. The direction is preset for the Y scribe on the substrate. Next, for a second scribing operation along dotted line 202 , the wheel is raised and the head is moved from position b to position c in the direction indicated by dotted line 221 . The wheel then performs a second scribing operation from position c to position d in the Y direction shown by solid line 212 .

[0040]When the wheel reaches position h after repeating this operation, the head on which the wheel is mounted is raised and then moved to position i in the direction shown by dot-dash line 222 for marking in the X direction.

[0041] Next, the wheel mounted on the head performs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com