A radiation crosslinked high temperature resistant low smoke halogen free flame retardant insulated wire

An insulated wire, cross-linked insulation technology, applied in insulated cables, insulated conductors, circuits, etc., can solve the problems of wire aging, aggravated fire, poor processing fluidity, etc., to achieve convenient installation and maintenance, improve production efficiency, and temperature resistance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

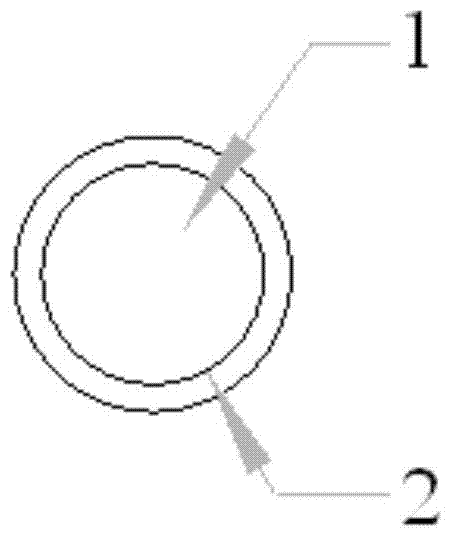

[0030] A radiation crosslinked high temperature resistant low smoke halogen free flame retardant insulated wire, its structure is as follows figure 1 As shown, it consists of an annealed oxygen-free copper conductor 1 and an irradiation cross-linked insulating layer 2 wrapped outside the annealed oxygen-free copper conductor 1 .

[0031] Among them, the radiation cross-linked insulating layer 2 is based on the EVA / HDPE blend system, and the resin-based modifier MPOE, the cross-linking auxiliary agent DPS, the compatibilizer PPA masterbatch and the flame retardant Mg(OH) are added. 2 , wherein, the weight ratio of EVA / HDPE is 70:30, the weight ratio of EVA / HDPE blending system and resin-based modifier is 80:20, the above two components constitute the compound, crosslinking aid and mixing The weight ratio of the materials is 2:100, the content of the compatibilizer in the mixture is 0.05wt%, and the content of the flame retardant in the mixture is 0.15wt%.

[0032] A special lo...

Embodiment 2

[0034] A radiation-crosslinked high-temperature-resistant, low-smoke, halogen-free, flame-retardant insulated wire is composed of an annealed oxygen-free copper conductor and a radiation-crosslinked insulating layer wrapped around the annealed oxygen-free copper conductor, wherein the radiation-crosslinked insulating layer is composed of The EVA / HDPE blend system is used as the base material, and the resin-based modifier MPOE, the cross-linking aid DPS, the compatibilizer fluoropolymer and the flame retardant Al(OH) are added 3 , wherein, the weight ratio of EVA / HDPE is 70:30, the weight ratio of EVA / HDPE blending system and resin-based modifier is 80:20, the above two components constitute the compound, crosslinking aid and mixing The weight ratio of the materials is 2:100, the content of the compatibilizer in the mixture is 0.05wt%, and the content of the flame retardant in the mixture is 0.15wt%.

[0035] A special low-smoke and halogen-free extruder is used to prepare the ...

Embodiment 3

[0037] A radiation-crosslinked high-temperature-resistant, low-smoke, halogen-free, flame-retardant insulated wire is composed of an annealed oxygen-free copper conductor and a radiation-crosslinked insulating layer wrapped around the annealed oxygen-free copper conductor, wherein the radiation-crosslinked insulating layer is composed of The EVA / EPDM blend system is used as the base material, and the resin-based modifier MPOE, the cross-linking aid DPS, the compatibilizer fluoropolymer and the flame retardant Al(OH) are added 3 , wherein, the weight ratio of EVA / EPDM is 70:30, the weight ratio of EVA / HDPE blending system and resin-based modifier is 80:20, the above two components constitute the mixture, and the crosslinking aid and the mixing The weight ratio of the material is 2:100, the content of the compatibilizer in the mixture is 0.05wt%, and the content of the flame retardant in the mixture is 0.16wt%. Copper agent, ammonium octamolybdate, clay and nano calcium carbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com