Drag chain coverage method for movable workbench of press machine

A technology for moving worktables and presses, applied in presses, manufacturing tools, etc., can solve the problems of reducing equipment life, increasing impact force, and complex structure, reducing on-site noise, avoiding jams, and improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

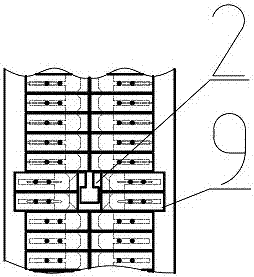

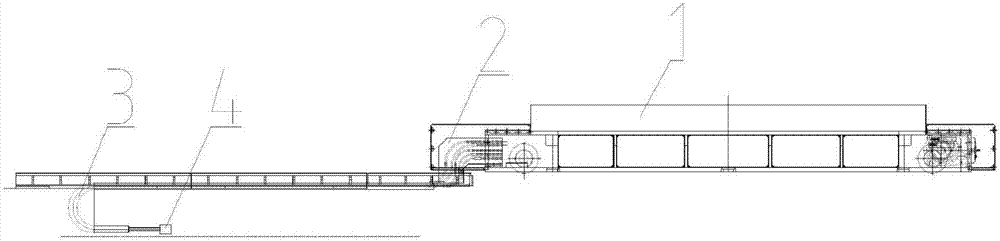

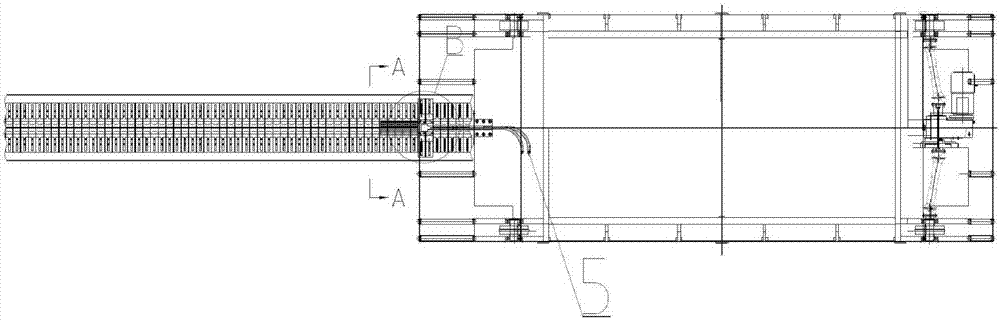

[0024] According to the first embodiment of the present invention, a drag chain covering method for a press mobile workbench is proposed, with Figure 1-4 Disclosed is a drag chain covering structure used in a drag chain covering method for a press mobile workbench of the present invention, the structure includes a movable workbench 1, a push head 2, a drag chain 3, pipelines and / or cables on the equipment foundation Interface 4, pipeline and / or cable interface 5 on the mobile workbench, equipment foundation 6, I-beam 7, bracket 8, cover plate 9, movable plate 10, spring 11, through this structure, the drag chain is covered by the cover The lateral opening and closing of the board in the horizontal plane is done.

[0025] Specifically, a push head 2 is fixed on the movable workbench 1 of the press, and the push head can move along with the moveable workbench. The pipeline and / or cable interface 4 on the equipment foundation is fixed on the equipment foundation 6. The pipeline...

Embodiment 2

[0029] In this embodiment, as an improvement to Embodiment 1, a vibration-damping layer is arranged on the contacting surface of the cover plates 9 on both sides. Other structures are the same as Embodiment 1. Generally speaking, the two The side cover plate 9 can prevent a large collision by controlling its closing gap during design, but by arranging a damping layer on the contacting surface of the cover plate 9 on both sides, the cover plate 9 is further eliminated. Noise that may be generated during reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com