Construction method for large bearing capacity pile and pile foundation and inner hole deposition device

A construction method and technology of bearing capacity, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high pile foundation cost and low pile bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

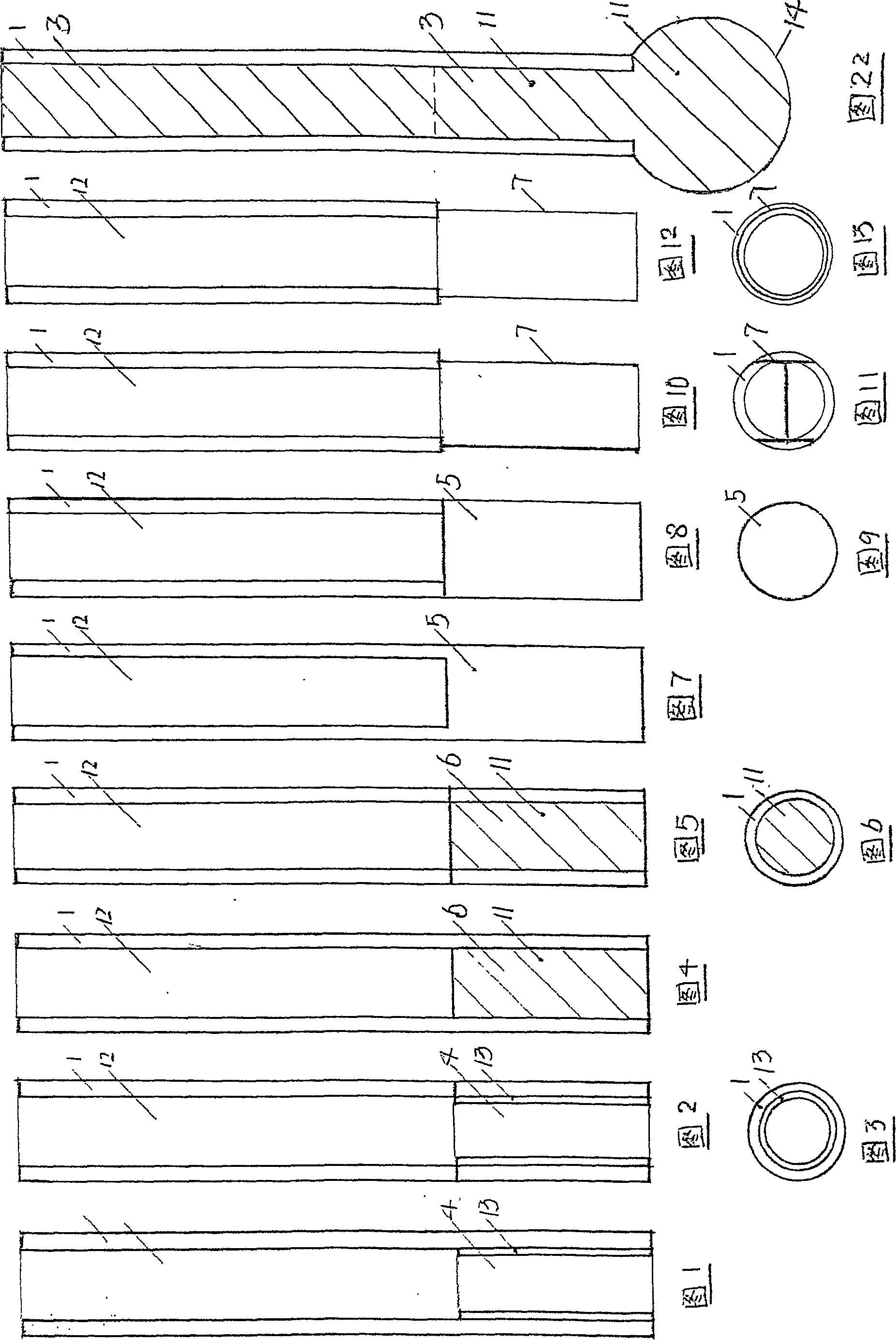

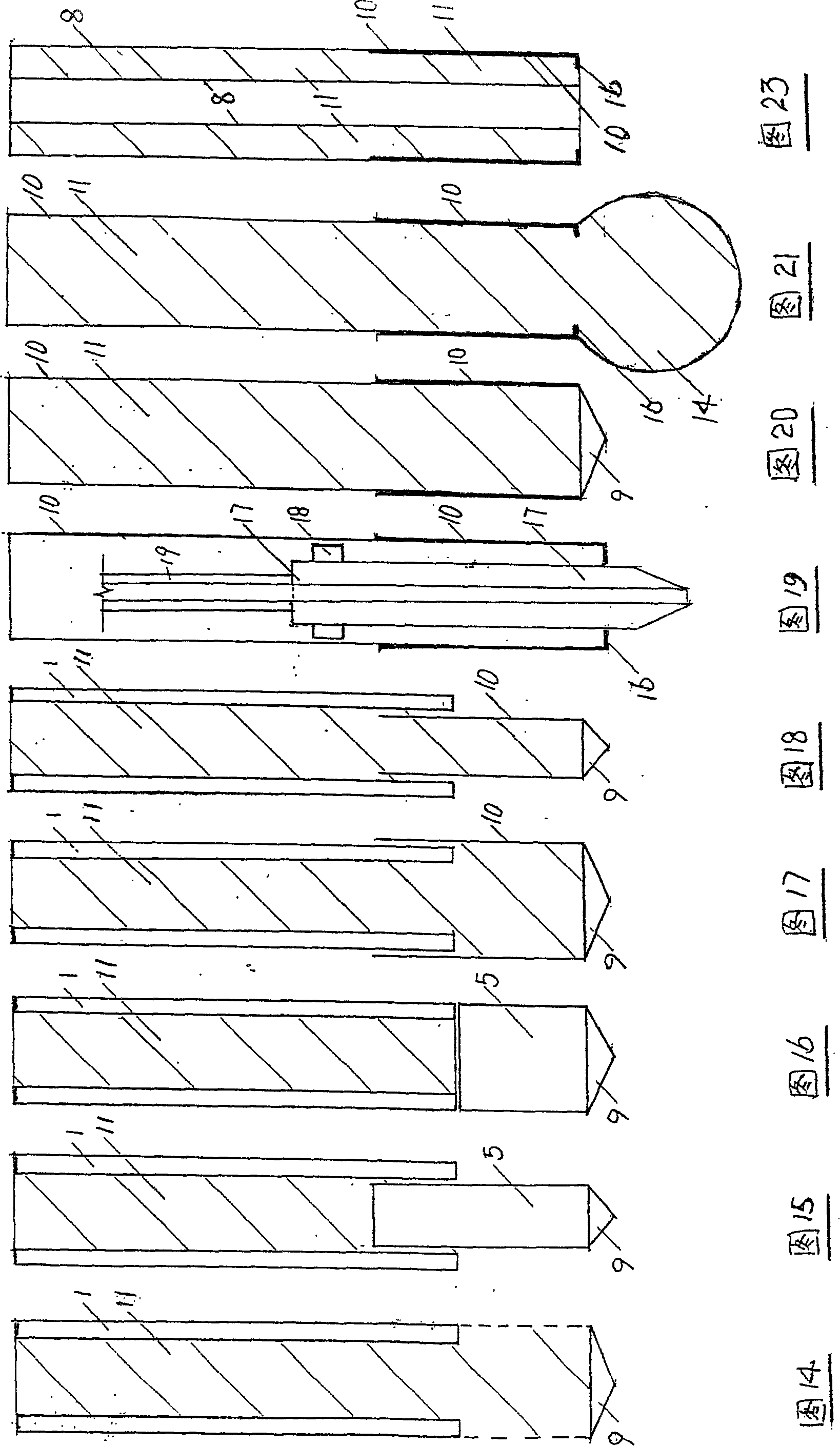

[0154] Example 1. It can be seen from Fig. 1 and Fig. 3 that this embodiment 1 is a concrete hollow pile with a large bearing capacity and an anti-softening section.

[0155] product features. It comprises hollow pile body (1), pile core (12), pile point (9) (not drawing), is characterized in that: also comprises anti-softening section, and anti-softening section is hollow pile section (4), and hollow pile section (4) and the hollow pile body (1) are the same joint and body. The hollow pile section (4) is arranged at the lower end of the hollow pile; the length of the hollow pile section (4) is not less than the length of the pile body entering the bearing layer; the optimum length of the hollow pile section (4) is between 1-4 meters. The hollow pile section (4) includes a layer of sealing layer (13), and the sealing layer (13) is arranged on the inner wall position of the hollow pile body (1), or is arranged on the inner wall and the end face position; the most sealing laye...

Embodiment 2

[0157] Example 2. It can be seen from Fig. 2 and Fig. 3 that the present embodiment 2 is also a concrete hollow pile with a large bearing capacity with an anti-softening section.

[0158] product features. The hollow pile section (4) serving as the anti-softening section is an independent body; the concrete hollow pile is formed by connecting one section of the independent body hollow pile section (4) and another section or several sections of the concrete hollow pile body (1).

[0159] Construction method characteristics. The concrete hollow pile adopts A-prefabrication process, B-assembly process, and P-connection process. The semi-finished products (segmentation and fragmentation) are manufactured in the factory, and different piles and components are connected and assembled at the construction site, and then sinking into the underground rock and soil layer. The connection method adopts one or more of welding and mechanical connection. The sealing layer (13) of the holl...

Embodiment 3

[0161] Example 3. As can be seen from Fig. 4 and Fig. 6, the present embodiment 3 is a concrete hollow pile with a large bearing capacity of a core-filled pile section (6) with the same joint and body.

[0162] product features. The anti-softening section is the core-filled pile section (6). It includes a hollow pile body (1) and a pile core (12), and is characterized in that: the core-filling pile section (6) is arranged at the lower end of the hollow pile; the length of the core-filling pile section (6) is not less than the pile body entering the holding The length of the force layer; the optimal length of the core-filling pile section (6) is between 1-4 meters; the core-filling pile section (6) is the same section and body as the concrete hollow pile body (1). The pile is composed of a hollow pile body (1) and a filling body (11) filled in the pile core (12). The filling body (11) includes a rigid waterproof material, and the rigid waterproof material is made of a liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com