Loose-proof compacting mechanism used for foodstuff machinery

A technology of pressing mechanism and food machinery, applied in the direction of mechanical equipment, fixing devices, etc., can solve problems such as loosening, inconvenient disassembly and replacement of mechanisms, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

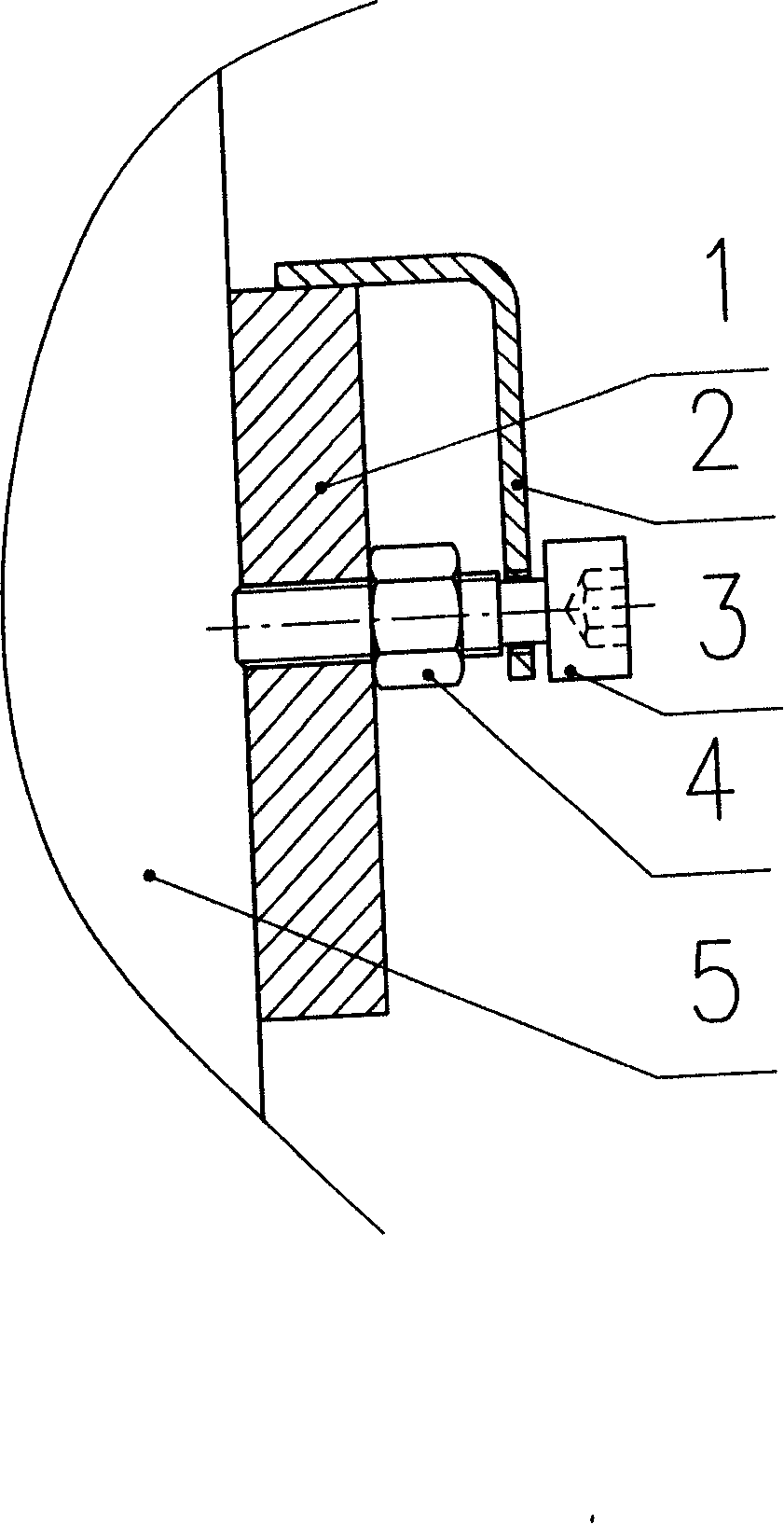

[0011] Such as figure 1 As shown, an anti-loosening compression mechanism for food machinery is composed of a pressing block, an anti-loosening plate, a compression screw, and a compression nut. The middle part of the briquetting block has a threaded hole, and the outer edge of the briquetting block is fixed with a loosening plate, and the compression screw compresses the pressed object and the briquetting block with a compression nut, and the locking plate is used to prevent loosening.

[0012] The compression screw 3 is screwed in from the anti-loosening plate 2, passes through the compression nut 4, and then unscrews the briquetting block 1 to compress the pressed part 5. The briquetting block 1 and the anti-loosening plate 2 are fixed together by methods such as welding. The compression screw 3 is not an ordinary hexagon socket head screw, and a small section of its head has no thread, and the outer diameter of the unthreaded part is processed to be slightly smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com