Self-tight-sealing high voltage introduction bar

A self-tightening sealing, high-voltage technology, applied in the direction of electric/magnetic refining, electric/magnetic dehydration/demulsification, etc., can solve the problems of arc ablation service life, inconvenient installation, easy leakage, etc. High pressure leakage resistance, high temperature resistance, easy installation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

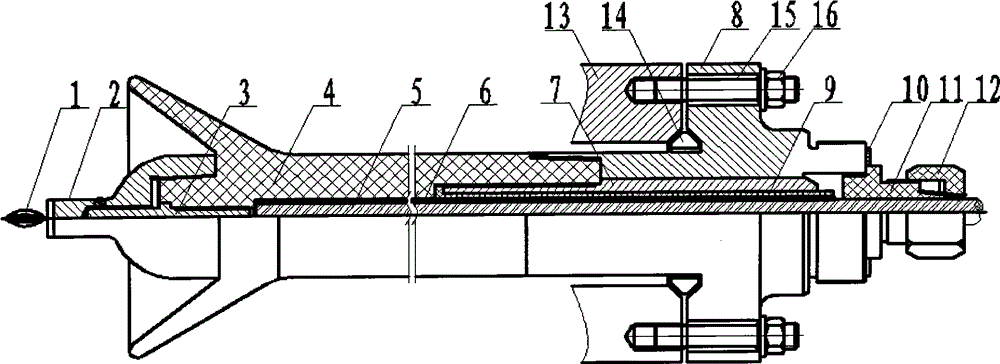

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

[0023] The self-tight sealing type high-voltage electric introduction rod includes a rod cap (2), a rod body (4) and a connecting seat (8), and a screw plug (3) is arranged inside the rod cap (2), rod body (4) and ), cables (5), high-pressure heat-shrinkable tubes (6), inner liners (7) and inner bushings (9), the structure also includes self-tightening joints (8), and connecting flanges matching the joints (13), seal (14) and connecting bolt (15), nut (16). The screw plug (3), the inner lining (7) and the rod body (4) are connected by tapered threads, the inner lining (7) is inserted with an inner bushing (9), and the high-pressure heat-shrinkable tube (6) is placed in the inner bushing Inside (9), there is a copper core inside the cable (5), through which high voltage electricity can be introduced into the tank, and a layer of high-voltage resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com