Touch panel

一种触摸板、薄膜的技术,应用在仪器、计算、电数字数据处理等方向,能够解决劣化显示器视觉辨认度等问题,达到视觉辨认度良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

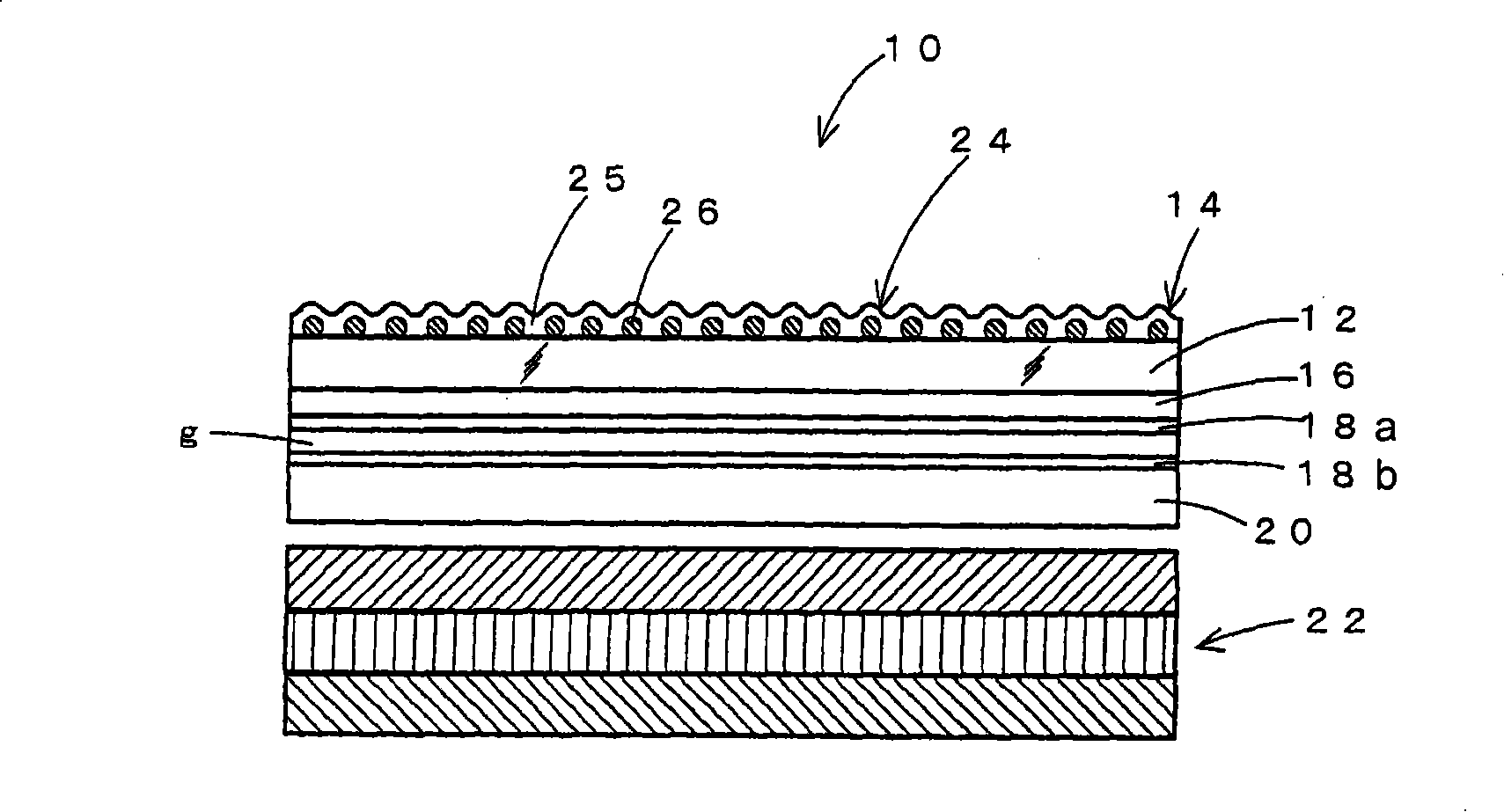

[0029] Embodiments of the present invention will be described below with reference to the drawings. figure 1 This shows the first embodiment of the present invention, and a touch panel 10 of this embodiment includes a touch panel film 14 formed of a transparent film base material 12 such as PET of about 180 to 200 μm, for example. On the back surface of the film 14 for a touch panel, a transparent electrode film 18 a such as an ITO film is formed in a predetermined pattern from the anchor layer 16 . The film 14 for the touch panel is fixed on the opposite surface of the catalyst plate substrate 20, and the transparent electrode film 18b is provided opposite to the transparent electrode film 18a on the catalyst plate substrate with a slight gap g. The touch panel substrate 20 is made of glass or transparent resin, and is fixed to the image surface of a display 22 such as liquid crystal.

[0030] For the film substrate 12 of the film 14 for a touch panel, for example, in additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com