Method for detecting abnormality of temperature sensor in machine tool

一种温度传感器、工作机械的技术,应用在温度计测试/校准、温度计、用直接对热敏感的电/磁性元件的温度计等方向,能够解决成本上升、温度传感器或温度测定装置数量增加等问题,达到成本上升抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

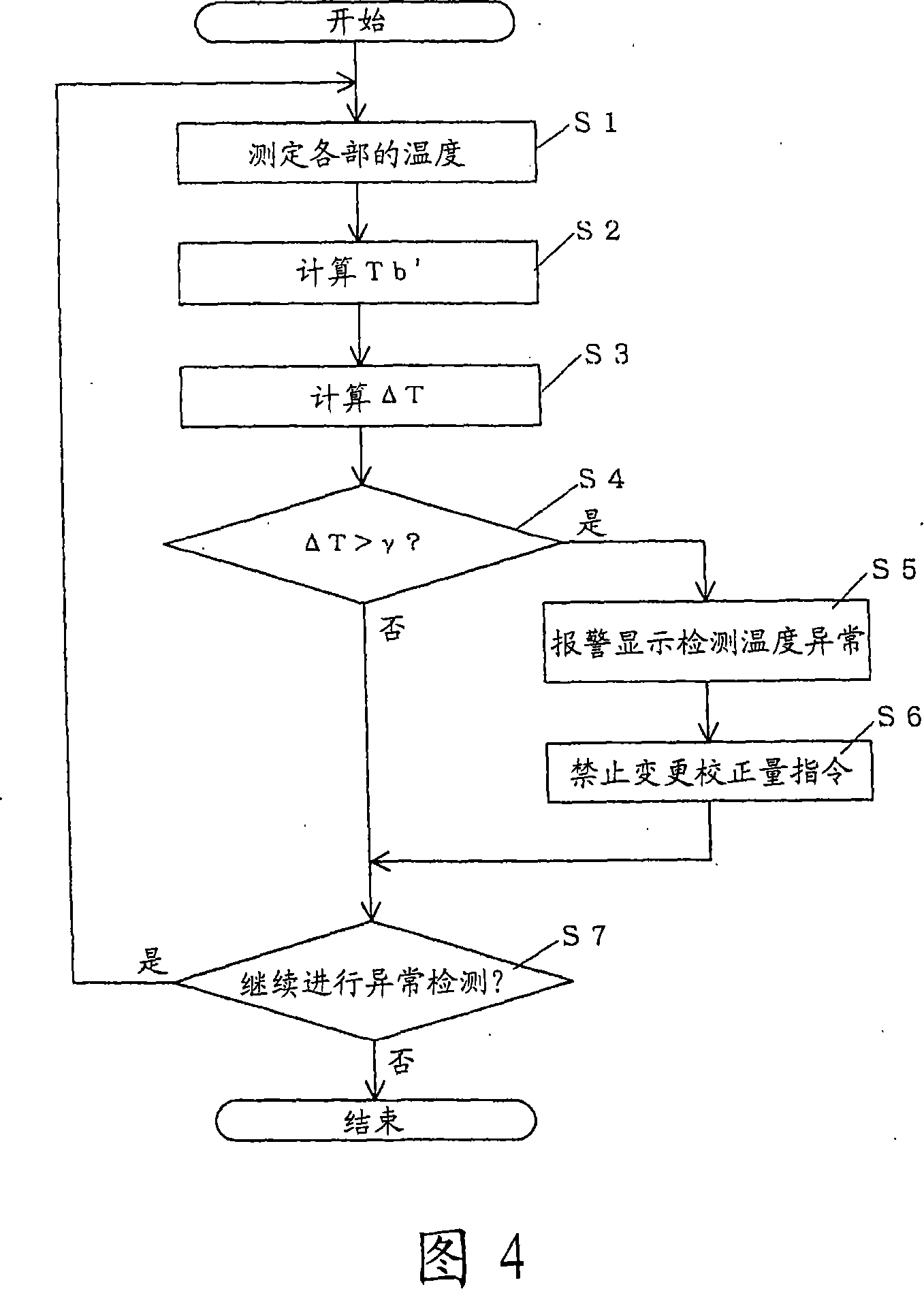

[0019] Embodiments of the present invention will be described below with reference to the drawings.

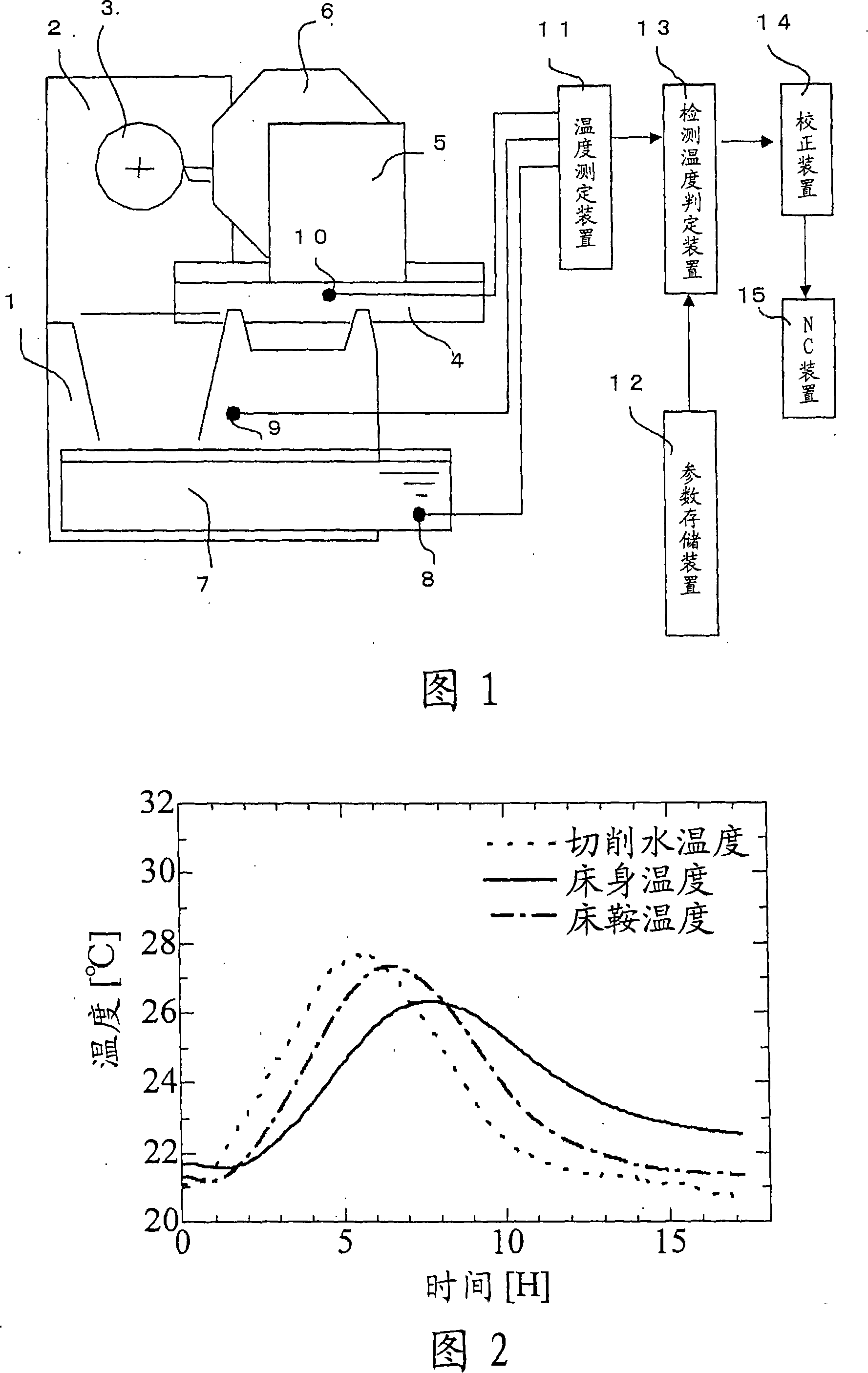

[0020] FIG. 1 is a schematic view of a lathe as an example of a machine tool viewed from the axial direction of a spindle. A headstock 2 is fixedly installed on the left upper surface of the bed 1 , and a chuck 3 is fixedly installed on the spindle protruding from the headstock 2 to hold a workpiece. A bed saddle 4 is placed on the guide rail on the upper surface of the bed 1 on the right side of the headstock 2, and a tool rest 5 is placed on the bed saddle 4 in a manner that can slide radially toward the main shaft. The cutting tool can be fixed on the outer peripheral surface of the turret (turret) 6 which is arranged in the manner of rotating the side of the side of 5 .

[0021] On the other hand, the bed 1 below the headstock 2 has holes for discharging chips and cutting water, and the discharged chips and cutting water are collected into the cutting water tank 7 .

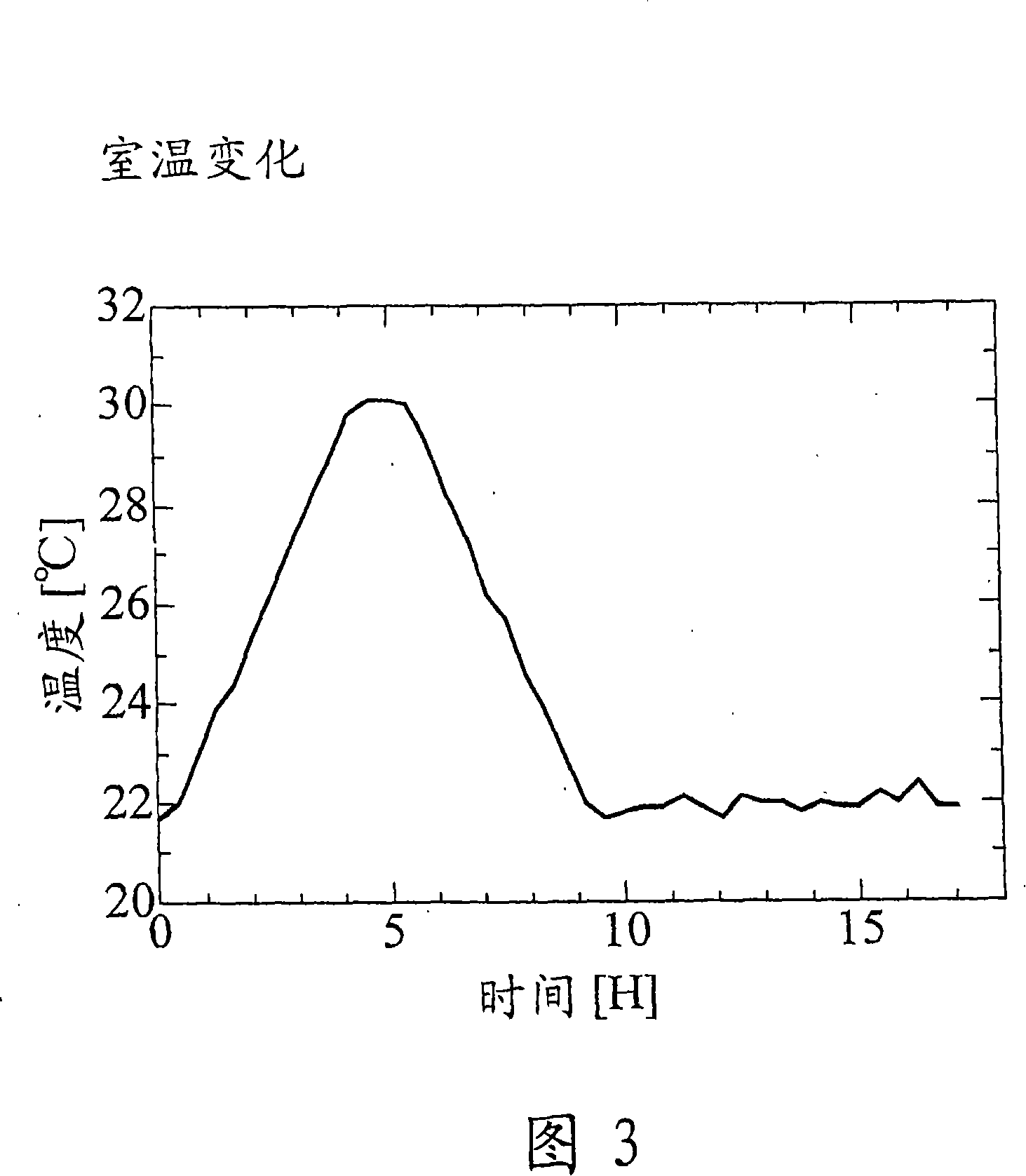

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com