Color-separation color-combination device for superelevation lightness digital cineprojector

A technology for digital movies and projectors, applied in the field of color separation and color combiners, can solve the problems of heat generation, heat dissipation problems and high difficulty of color separation and color combiners, and achieve the effect of excellent image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

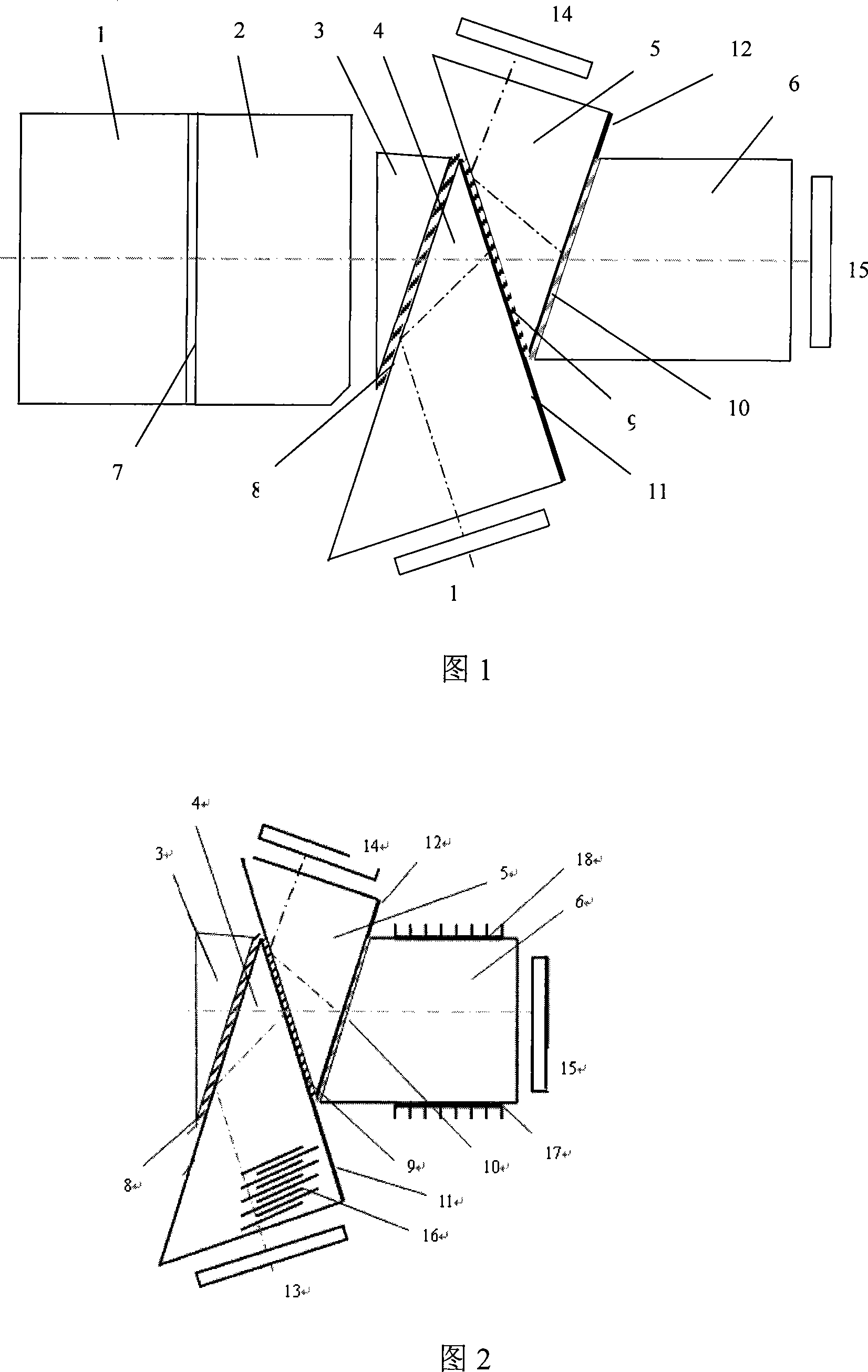

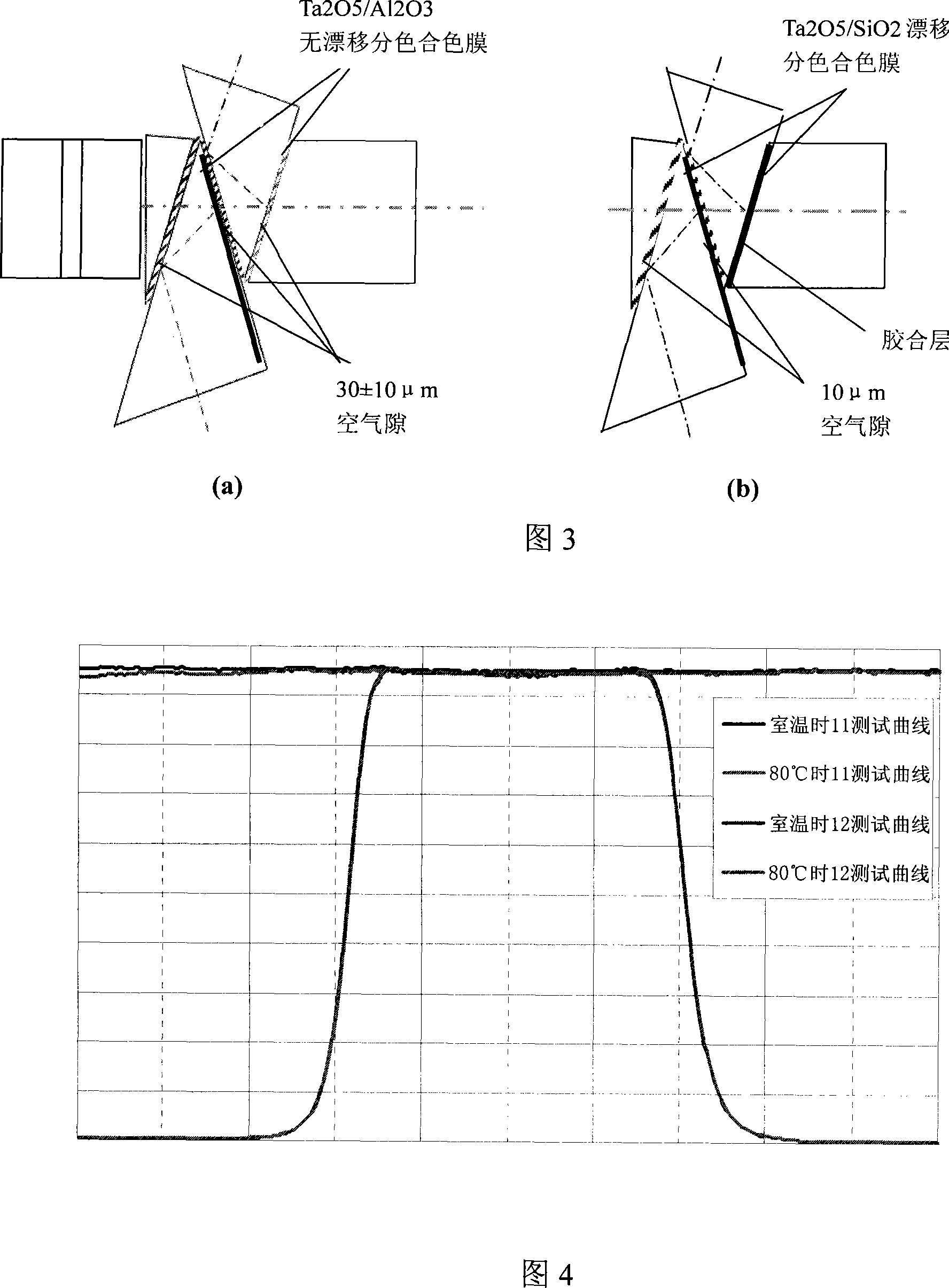

[0016] As shown in Figure 1, the color separation and color combiner for ultra-high-brightness digital cinema projectors is characterized in that the white light is completely reflected by the first total internal reflection prism 1 and then passes through the total internal reflection second prism 2, Phillips compensation Prism 3, Philips prism first air gap 8, after Philips anti-red prism 4, anti-red transparent blue-green color separation film 11 divides white light into two beams of light, red and blue-green, and one of them reflects red light Through the total reflection of the first air gap 8 of the Philips prism, it reaches the image chip 13 of the red light path, and the blue-green light transmitted by another beam passes through the Philips anti-blue prism 5 and is reflected by the blue-transparent-green color separation film 12 and then Divided into two beams of blue and green light, wherein one beam of reflected blue light is totally reflected by the second air gap 9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap