Method for manufacturing microphone diaphragm

A manufacturing method and microphone technology, applied to electrical components, sensors, etc., can solve problems such as low production efficiency, inconsistent product performance parameters, film damage, etc., and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

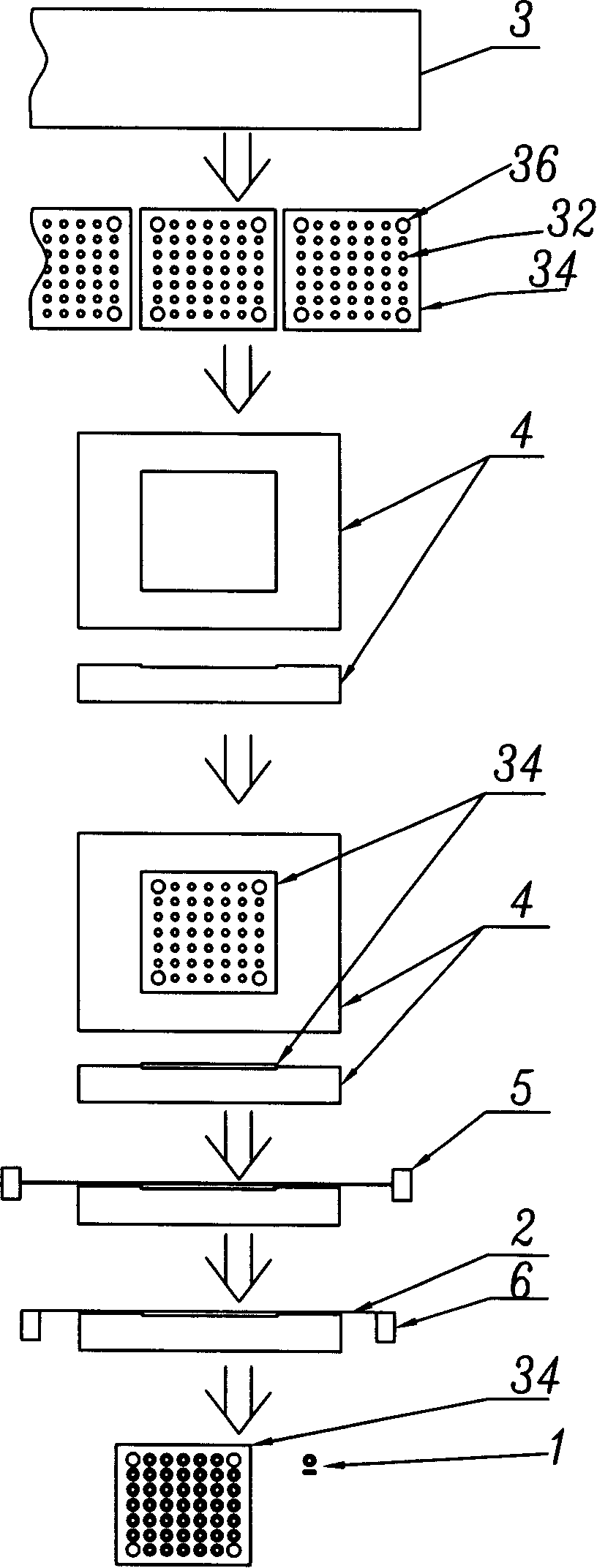

[0027] see figure 1 and figure 2 , the microphone diaphragm 1 of the present invention comprises a film ring (not shown in the figure) and the film 2 that is stuck on the film ring, and the film 2 is pasted on the metal diaphragm plate by a specific process method (see below for details), and then The film ring with the film 2 attached is punched out from the metal film plate. The diaphragm 1 requires good electrical conductivity and adhesive strength between the diaphragm 2 and the metal diaphragm plate, so as to ensure a high flatness of the diaphragm 2 and realize array formation and high-efficiency production. The specific steps of manufacturing the above diaphragm 1 are as follows:

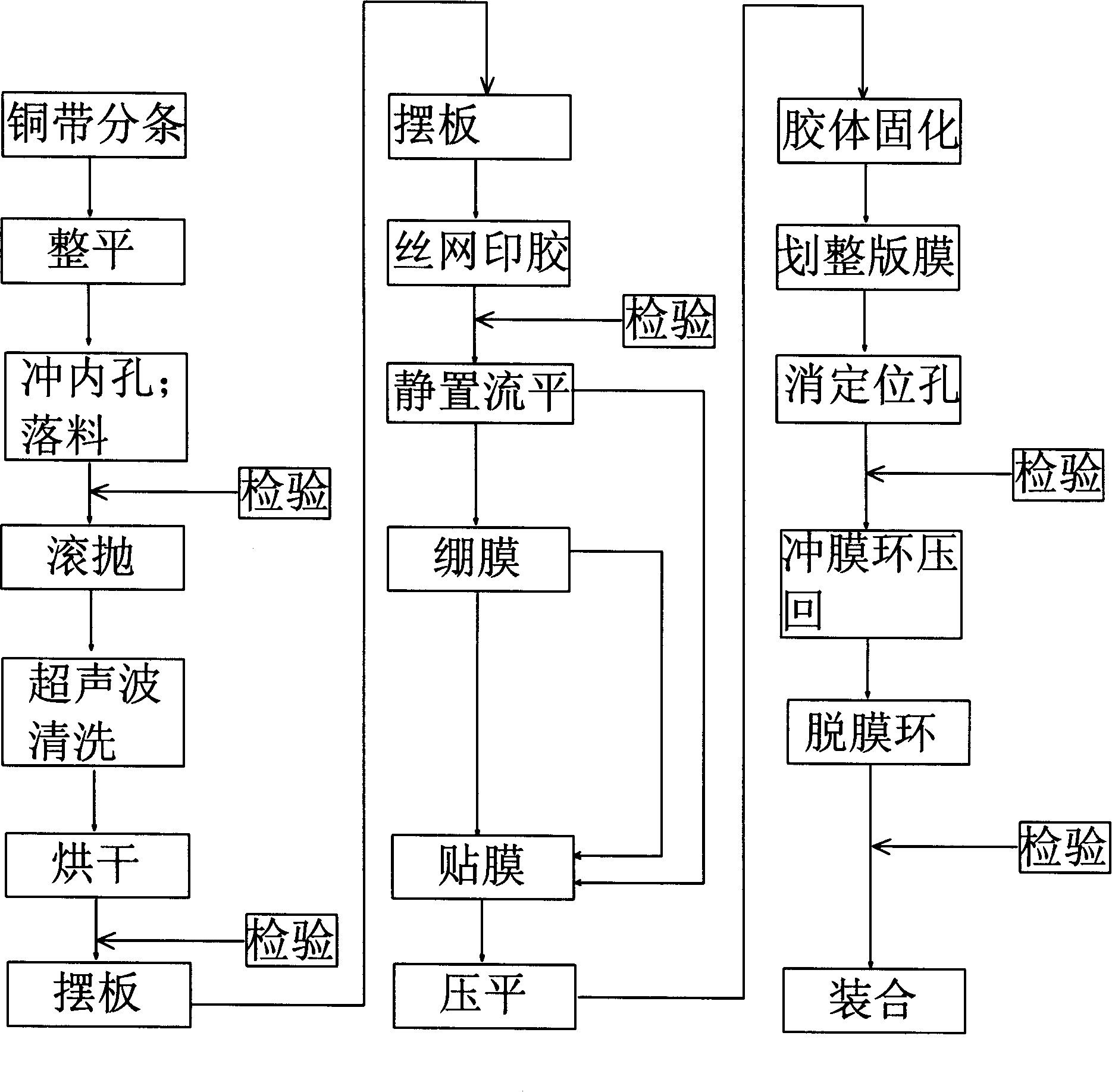

[0028] (1) Firstly, the metal strip 3 with a certain thickness that can be used to make the film ring is properly slit to be divided into metal strips of a certain size (not shown in the figure), and then precisely leveled.

[0029] (2) Slitting the metal strip into strips, punching out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com