Copper strip welding method and lithium cell adopting the copper polar ear

A welding method and technology for lithium batteries, which are applied in welding equipment, welding accessories, battery pack parts, etc., can solve the problems of difficult welding of copper electrodes and high production costs, and achieve the advantages of simple production process, resource saving and production cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

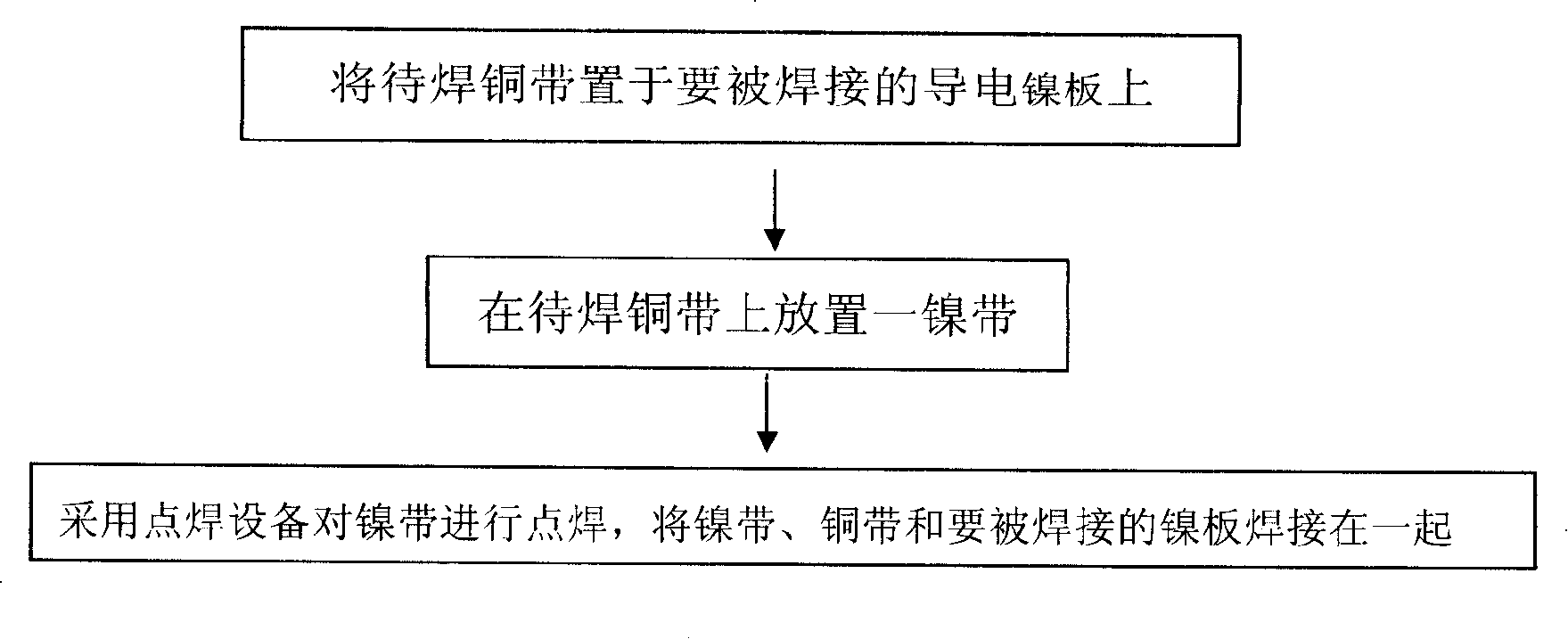

[0034] Embodiment 1, a kind of welding method of copper strip, as image 3 shown, including the following steps:

[0035] The first step: place the copper strip to be welded on the conductive metal piece to be welded;

[0036] The second step: place another nickel strip on the copper strip to be welded;

[0037] Step 3: use spot welding equipment to spot weld the nickel strip, and weld the nickel strip, copper strip and the metal parts to be welded together. The welding current for spot welding is 100-150KA, the welding time and pulse width are 1-2 3ms, preferably: welding current 115-135KA, welding time and pulse width 1.5-2.5ms.

[0038] Step 4: Cut off the excess nickel strip at the weld.

Embodiment 2

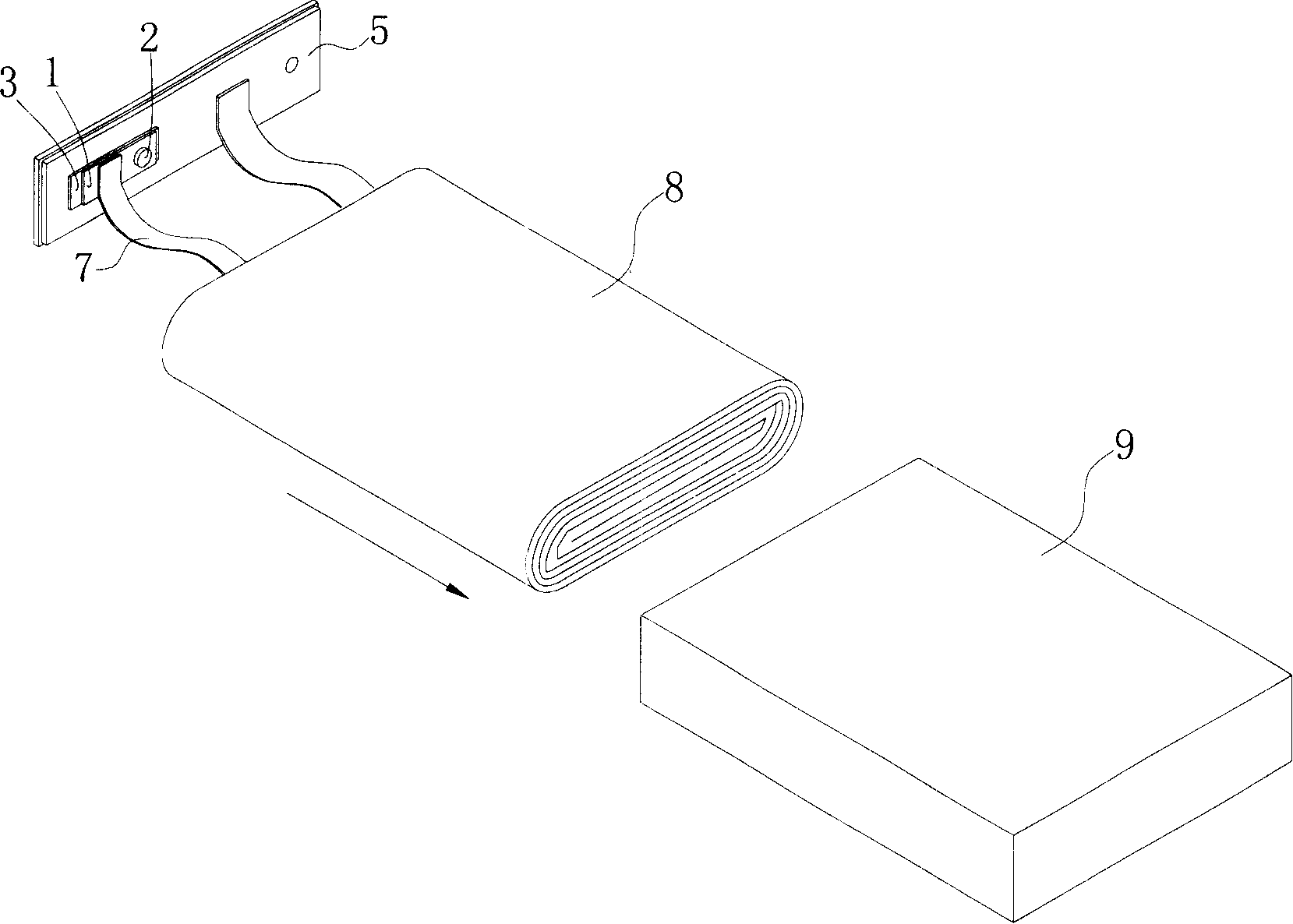

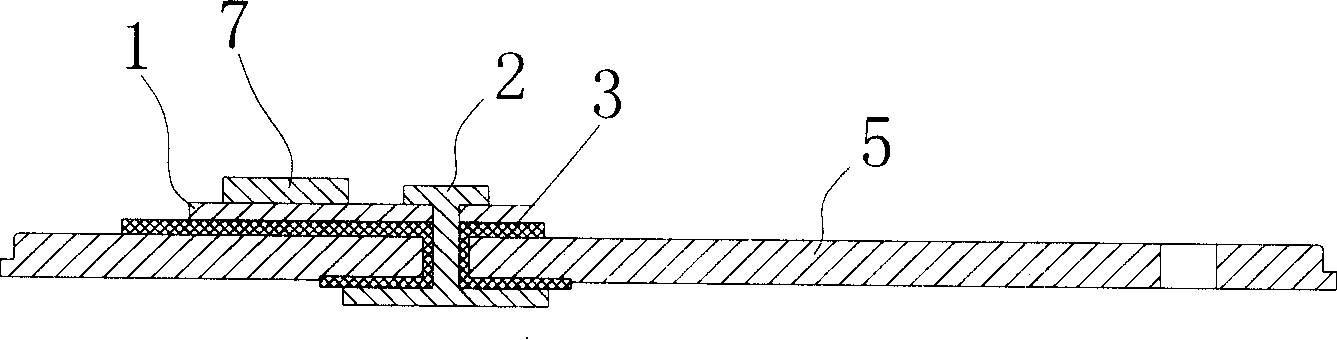

[0039] Embodiment 2, a lithium battery using copper tabs, such as Figure 4 and Figure 5 As shown, it includes a battery cover plate assembly, a battery case 9, an electrolyte (not labeled in the figure), and a cell unit 8 wound by positive and negative electrodes and separator paper, and a nickel sheet (or nickel strip) 4 . Wherein the battery cover plate assembly includes a pressure plate 1, a cover plate 5, a connector 2 and a sealing insulator 3. The pressure plate 1 can be a copper plate, a steel plate or a conductive alloy plate. One of the negative tabs, the positive tab or the negative tab uses copper tabs 7 , and the sealing insulator 3 is located between the cover plate 5 and the pressure plate 1 to insulate them. The welding method of the copper tab 7 is to overlap the pressing plate 1 located inside the cover plate 5 and the nickel sheet 4 of the copper tab 7 in order and weld them together by spot welding. The welding current of the spot welding is 100-150KA. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com