Guide pin triangular adjusting mechanism for computer flat knitting machine

A technology of guide needle triangle and adjustment mechanism, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as time-consuming, heavy adjustment workload, and influence on knitting efficiency, so as to reduce workload and save adjustment the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

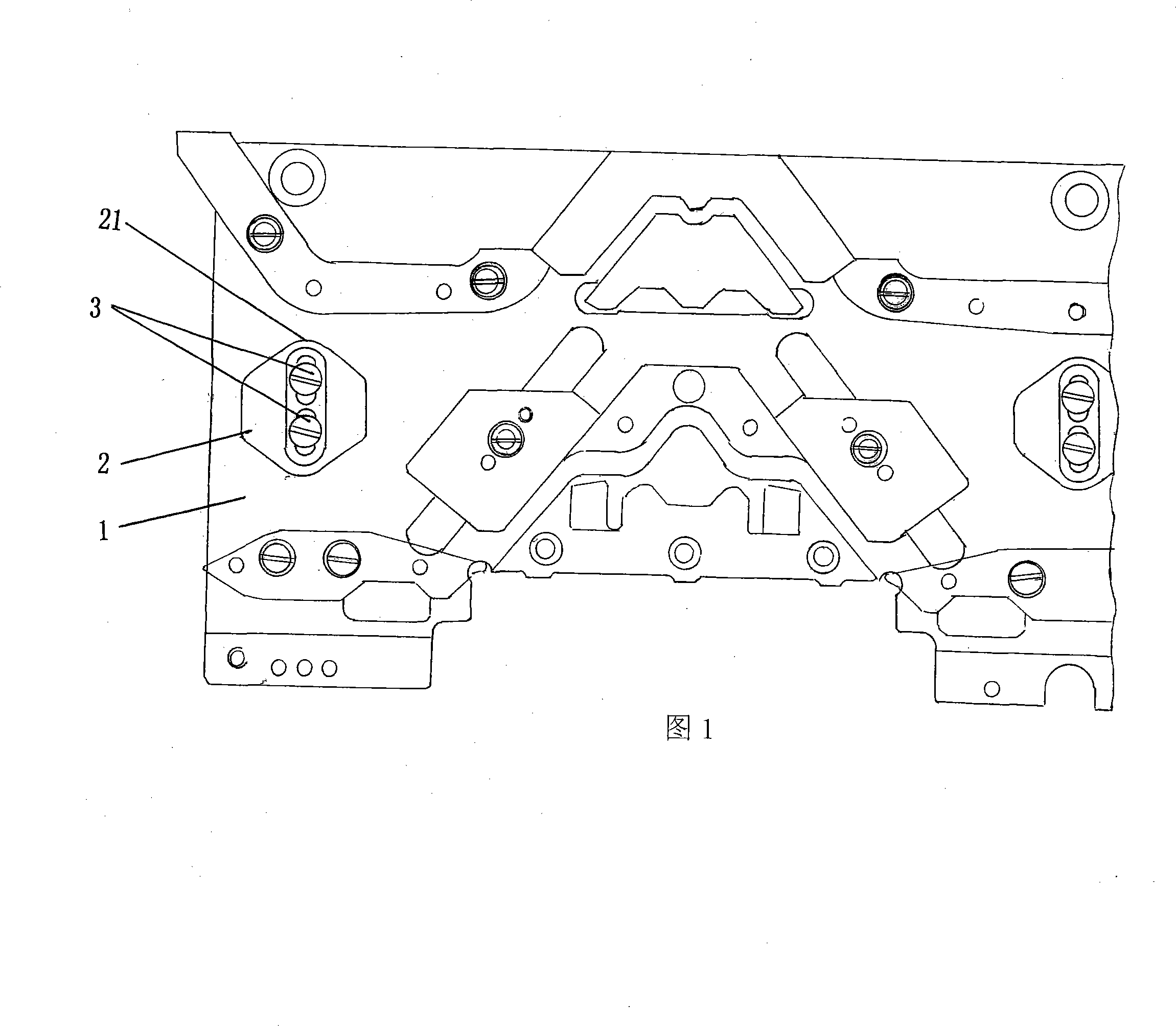

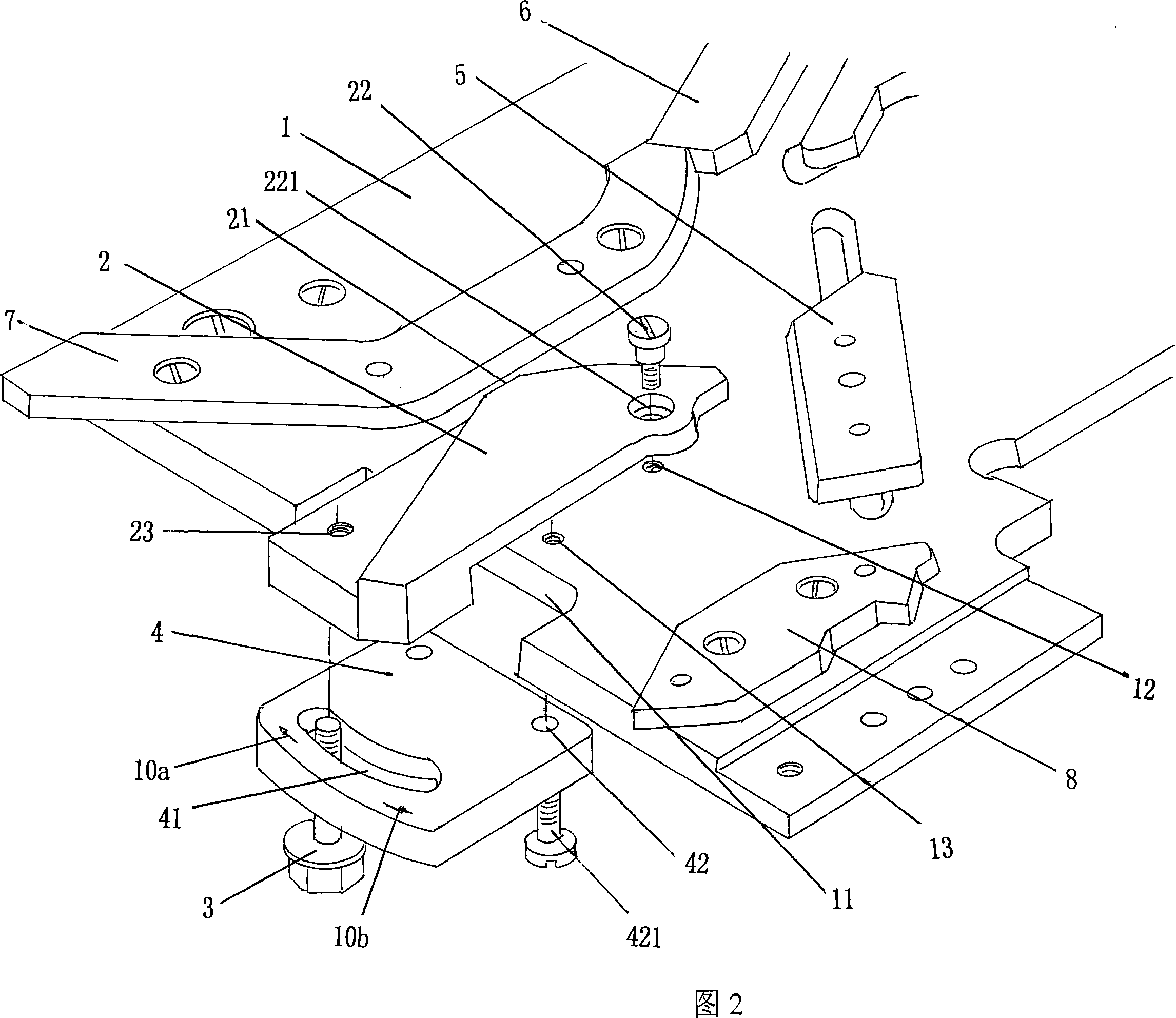

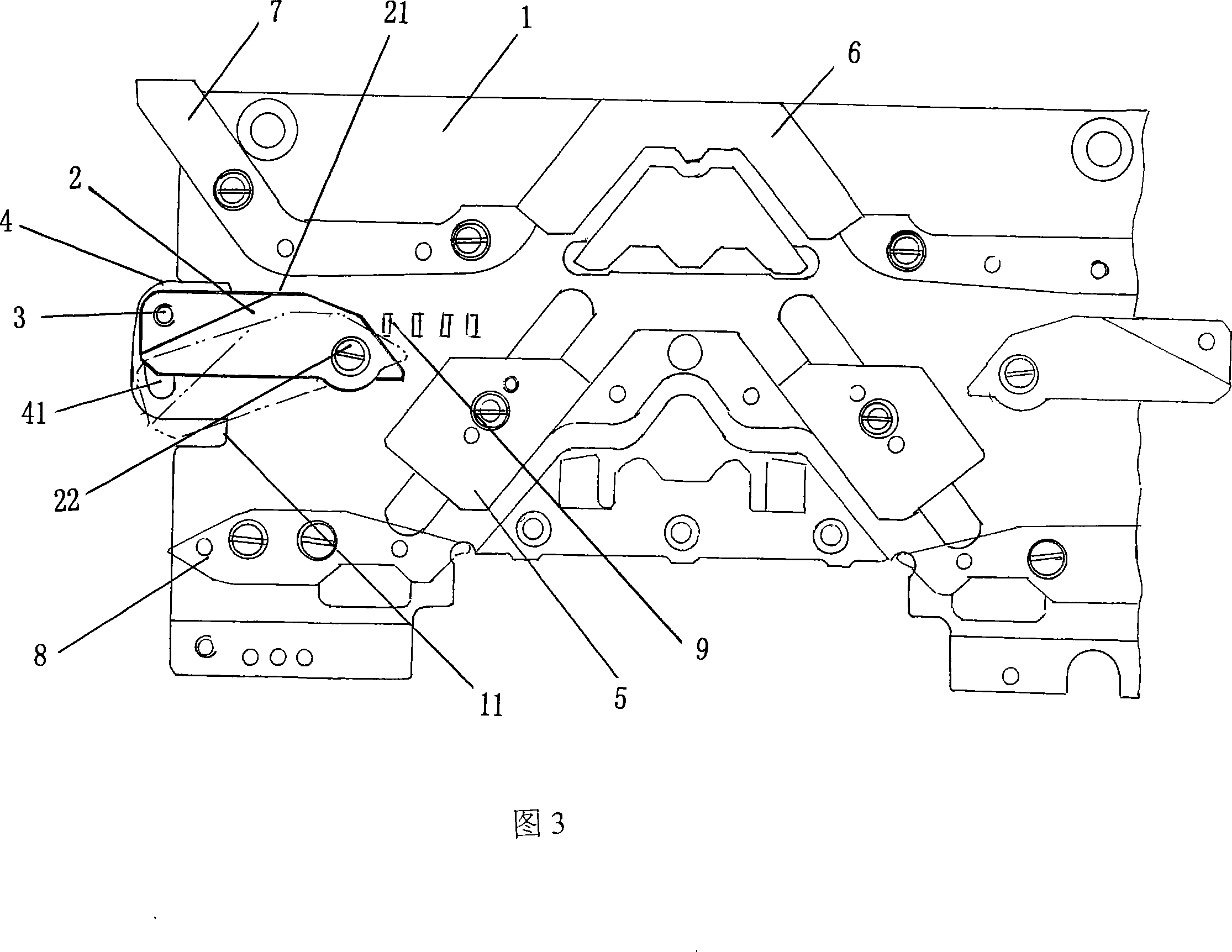

[0014] Please refer to Fig. 2, as the applicant claims in the above background technology column, the triangular bottom plate 1 is fixed on the machine head of the computerized flat knitting machine, and there is a pair in quantity, which is installed at the front and rear of the machine head side. One of the triangular bottom plates 1 is shown in the figure, and the triangular bottom plate 1 is equipped with a guide pin cam 2, a density cam 5, a herringbone cam 6, a first and a second guide cam 7 in the same way as in the prior art. , 8 and other triangles. As a feature of the technical solution of the present invention: a gap 11 is formed on both sides of the triangular base plate 1 corresponding to the position of the guide pin cam 2. In the figure, although the applicant only shows the gap 11 on the left side of the triangular base plate 1, However, it is completely understandable that the right side also has a notch 11, and the following statements are all for one of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap