Store cabinet discharging gauging method

A measurement method and technology of a wire storage cabinet, which are applied in the field of discharge measurement of the wire storage cabinet, can solve the problems of not being able to know the weight of the cut tobacco in a timely and accurate manner, errors, and manually judging the amount of the cut tobacco, so as to facilitate production scheduling and eliminate downtime. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

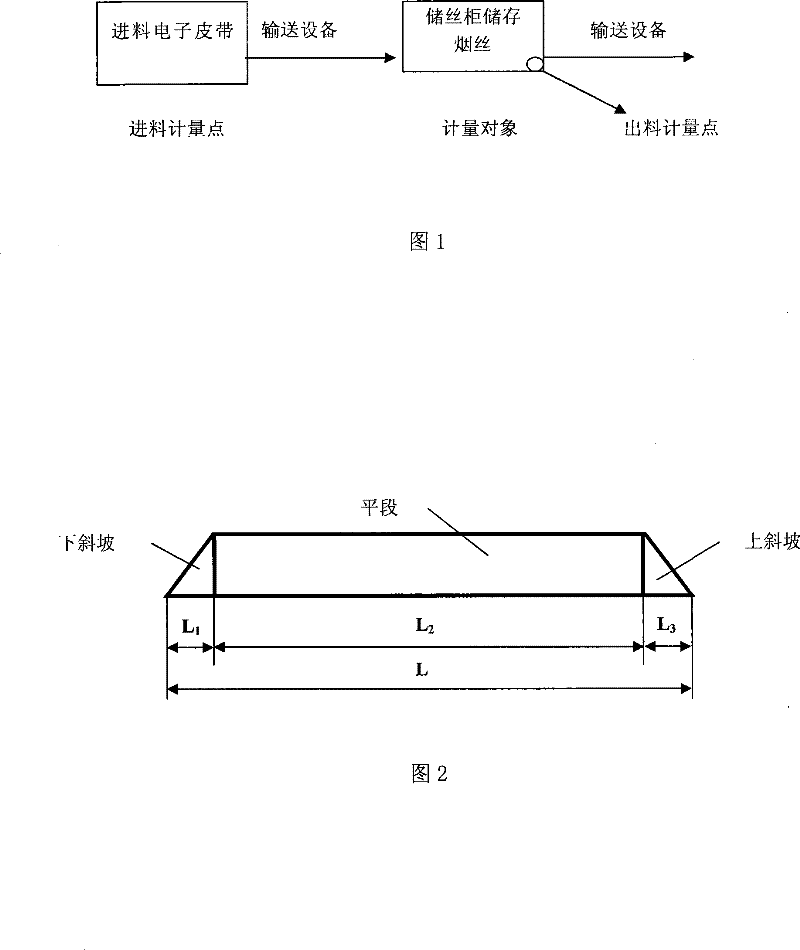

[0024] Through the technical transformation of hardware and software, the wire storage cabinet is enhanced into a new storage cabinet with automatic discharge metering function based on its own storage function, which expands the functionality of the wire storage cabinet. The metering process of incoming and outgoing materials is as figure 1 Shown.

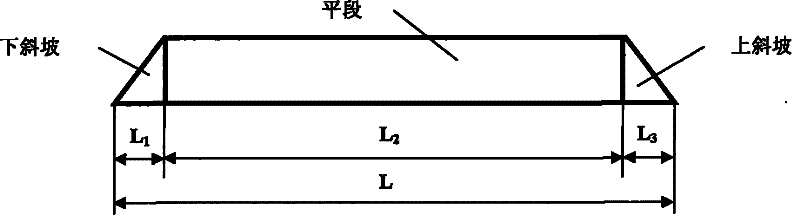

[0025] The equipment and mechanical characteristics of the wire storage cabinet are fixed, that is, the wire storage cabinets are all double-layer cabinets and work in the same way. After pouring, the weight of tobacco in the lower cabinet is equal to the weight of tobacco in the upper cabinet. The volume and shape of the shredded tobacco poured into the lower cabinet is slightly different, but it is basically trapezoidal. Moreover, the unit length of the bottom belt in each wire storage cabinet is consistent and measurab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com