Lever clip mechanism

A technology of levers and substrates, applied in file folders, printing, binding, etc., can solve the problems of hindering the pressing down of the ring parts, the ring part cannot be fully closed, and the cover is damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

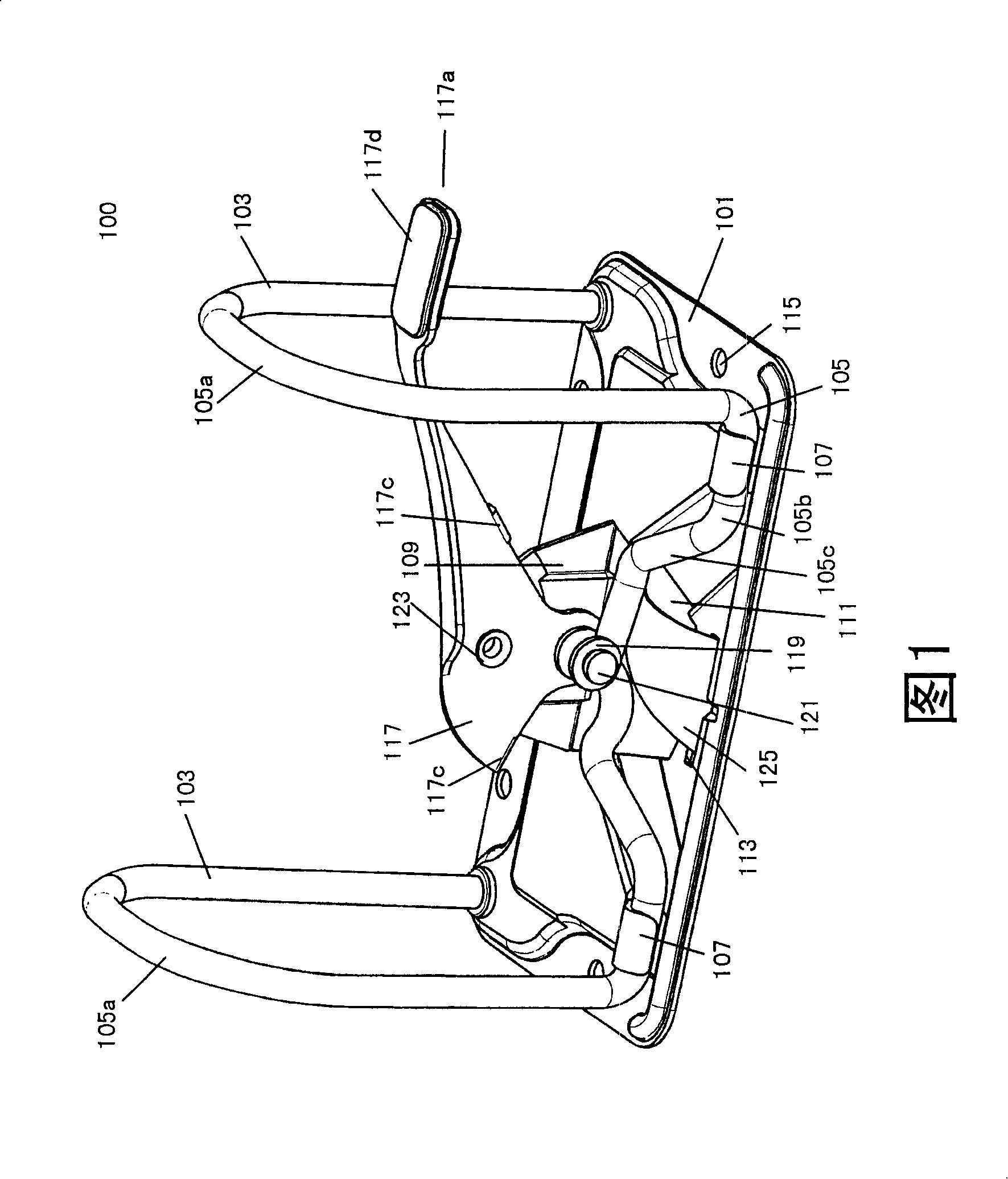

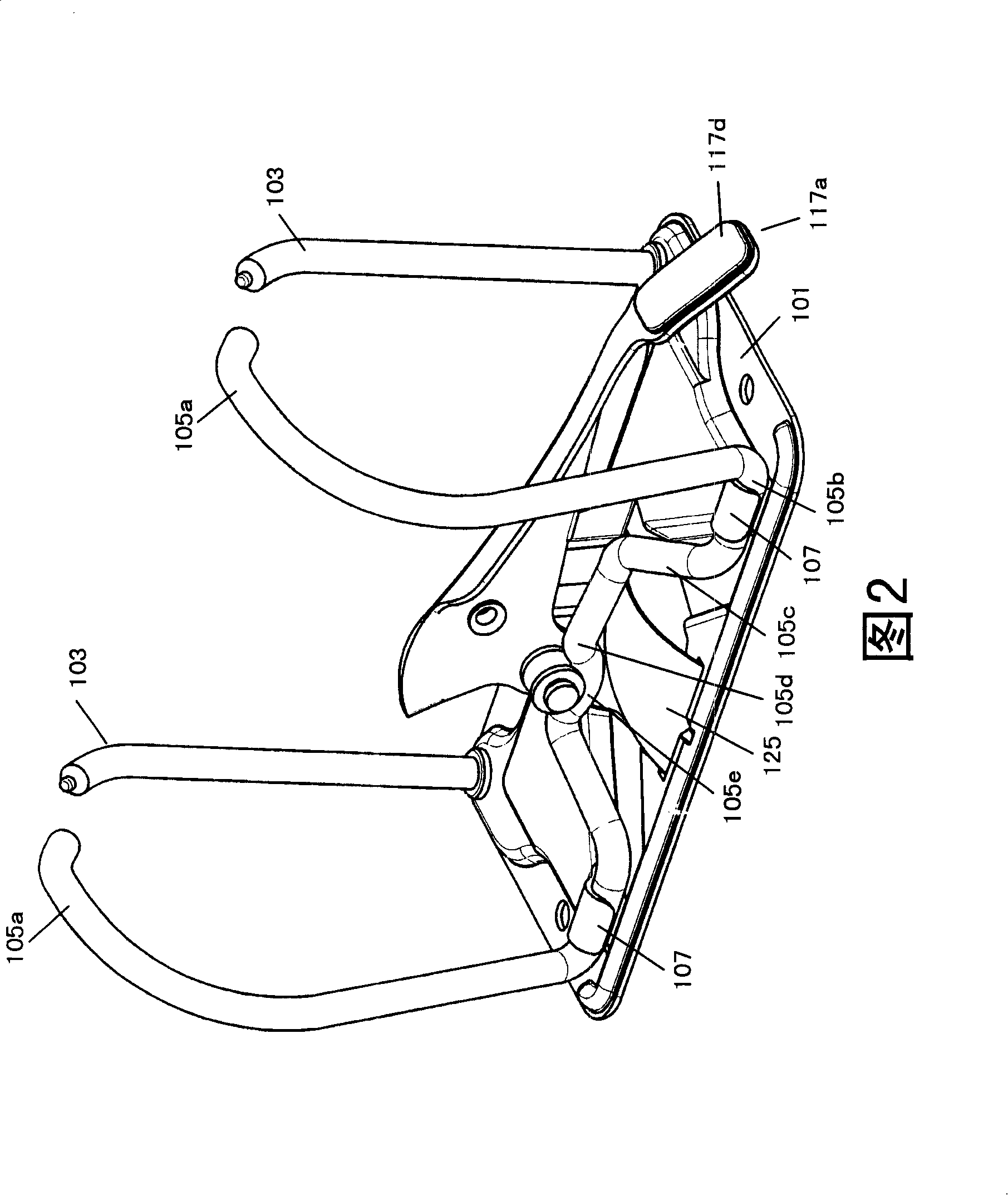

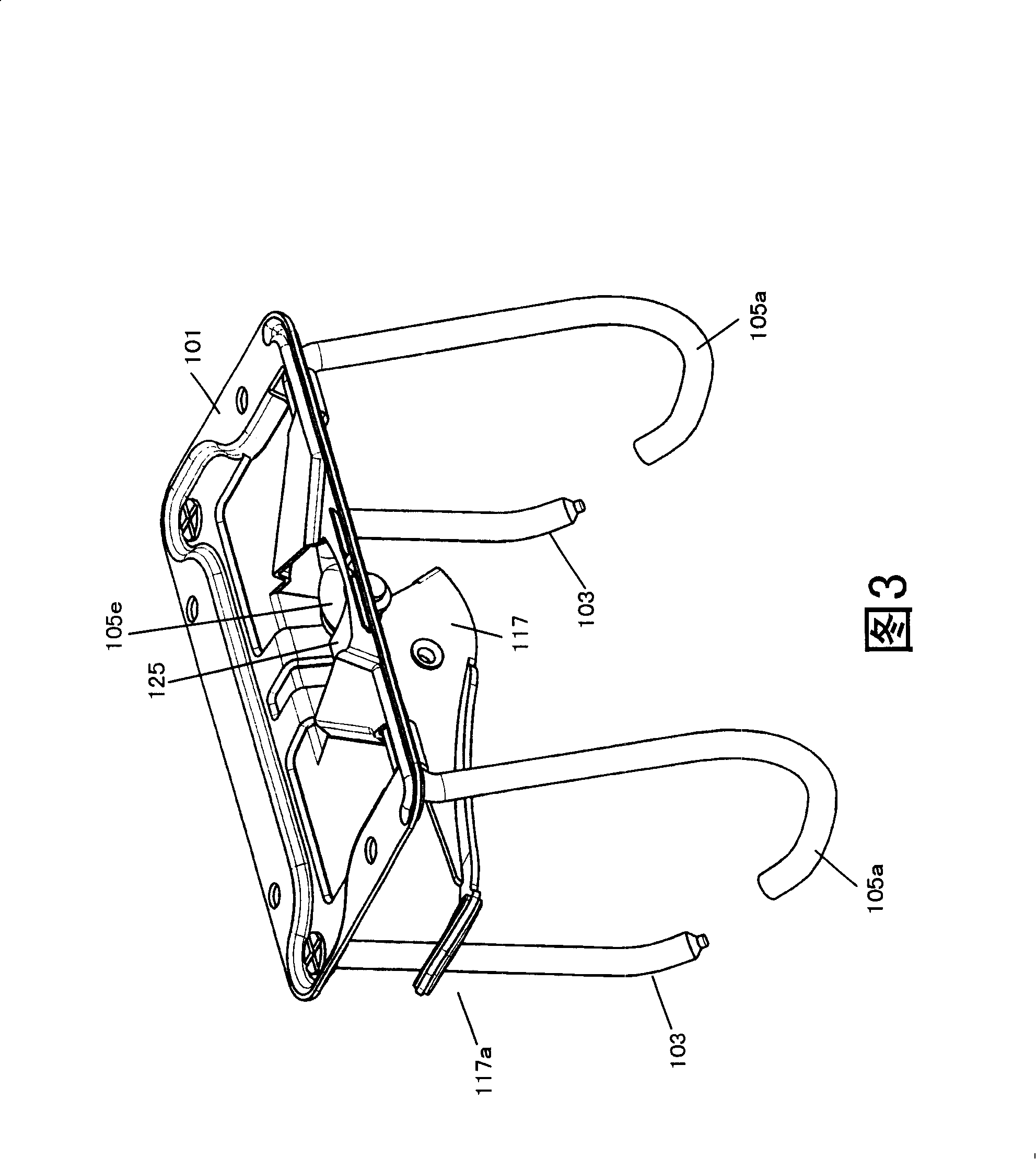

[0030] 1-4 show a lever clamp mechanism 100 according to a first embodiment of the present invention. The lever clamp mechanism 100 according to the first embodiment of the present invention includes a substantially flat base plate 101 . On one longitudinal side of the base plate 101 are fixedly mounted two mutually spaced apart and parallel first ring portions 103 extending substantially vertically upward from the base plate 101 and slightly bent at their free ends to form a bend. A ring member 105 is movably mounted on the other longitudinal side of the base plate 101 . The ring member 105 includes two second ring parts 105a spaced apart from each other and parallel to each other, and a connecting part 105b connecting the two second ring parts 105a into one body. Each second ring portion 105a is respectively formed with a bent portion at its free end, so that the two second ring portions 105a of the ring member 105 can cooperate with the corresponding opposite first ring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com