Device for automatically removing protective film of building partition wall slat made by extrusion forming of light-weight aggregates and film removing method thereof

A technology of extrusion molding and light aggregate, which is applied in the field of automatic membrane separation device, which can solve the problems of physical exertion, manual injury, and damage to slats, etc., and achieves the effect of short time, not easy to damage, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

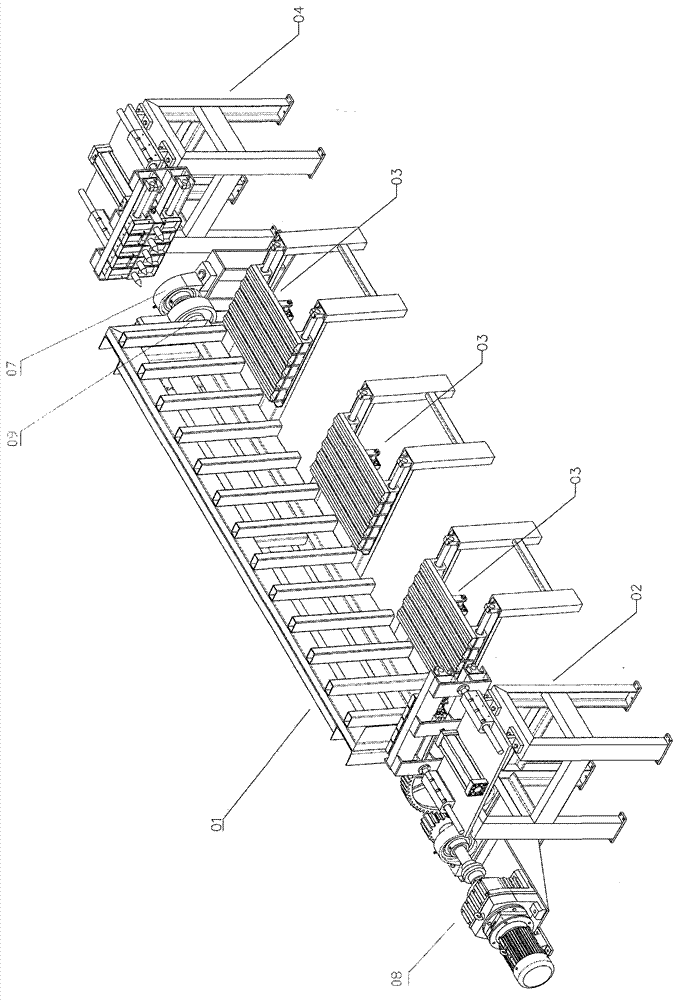

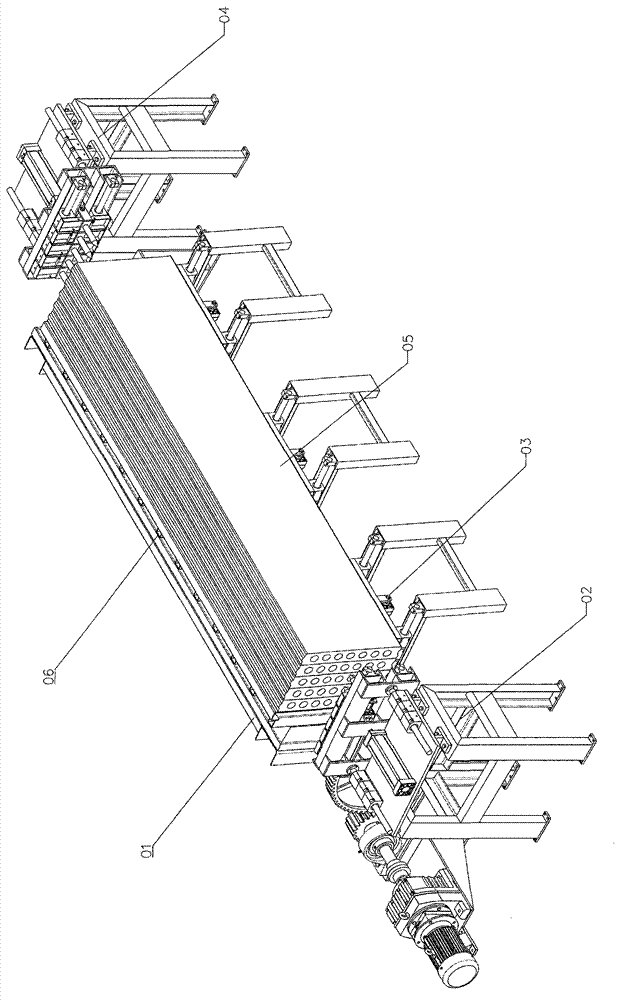

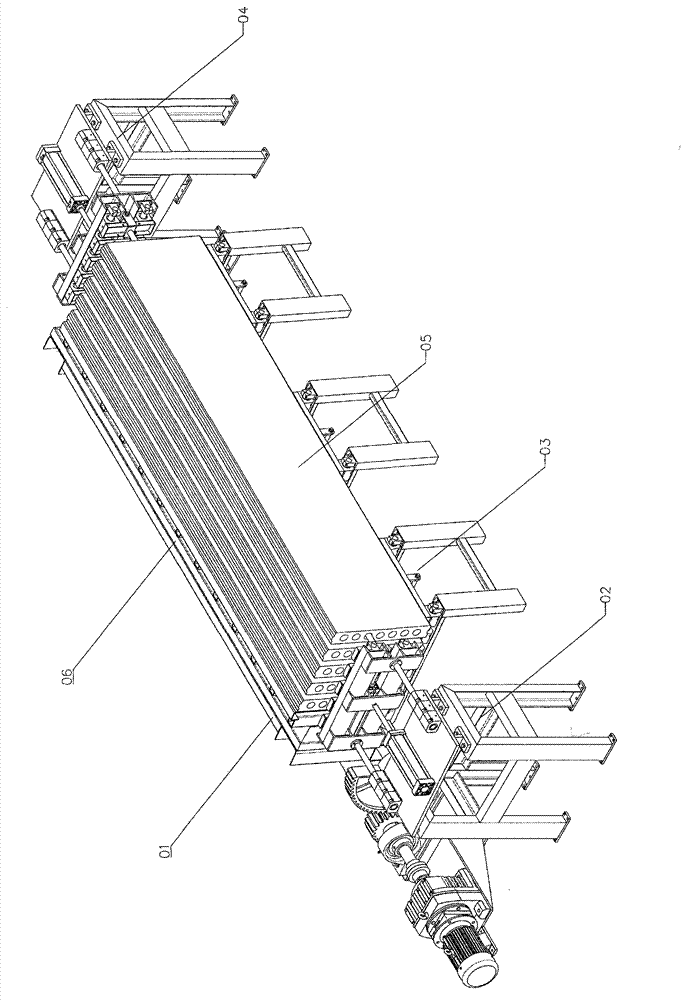

[0032] Such as figure 1 As shown, the automatic splitting film device for extruding and forming the protective film of building partition walls with light aggregates, including turning machine 01, left automatic inserting board splitting machine 02, convex air pressure pallet strip automatic splitting machine 03, right Automatic inserting board splitting machine 04 and operating table, in which the turning machine 01 and the convex air pressure pallet automatic splitting machine 03 are integrated structure, the bearing platform of the flipping machine 01 and the convex air pressure pallet automatic splitting machine 03 The carrying platform is at an angle of 90°, the left automatic plate opening and closing machine 02 and the right automatic plate opening and closing machine 04 are distributed on both sides of the convex air pressure pallet automatic opening and closing machine 03, and the operation console is used to output instructions. Control the movement of the whole devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com