Hot-water air conditioner and control method

A control method and air conditioner technology, which is applied to heating methods, air conditioning systems, heating and ventilation control systems, etc., can solve problems such as damaged compressors, insufficient refrigerant, and reduced work efficiency, so as to facilitate mass production, popularization and application, Increased hot water heating function and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

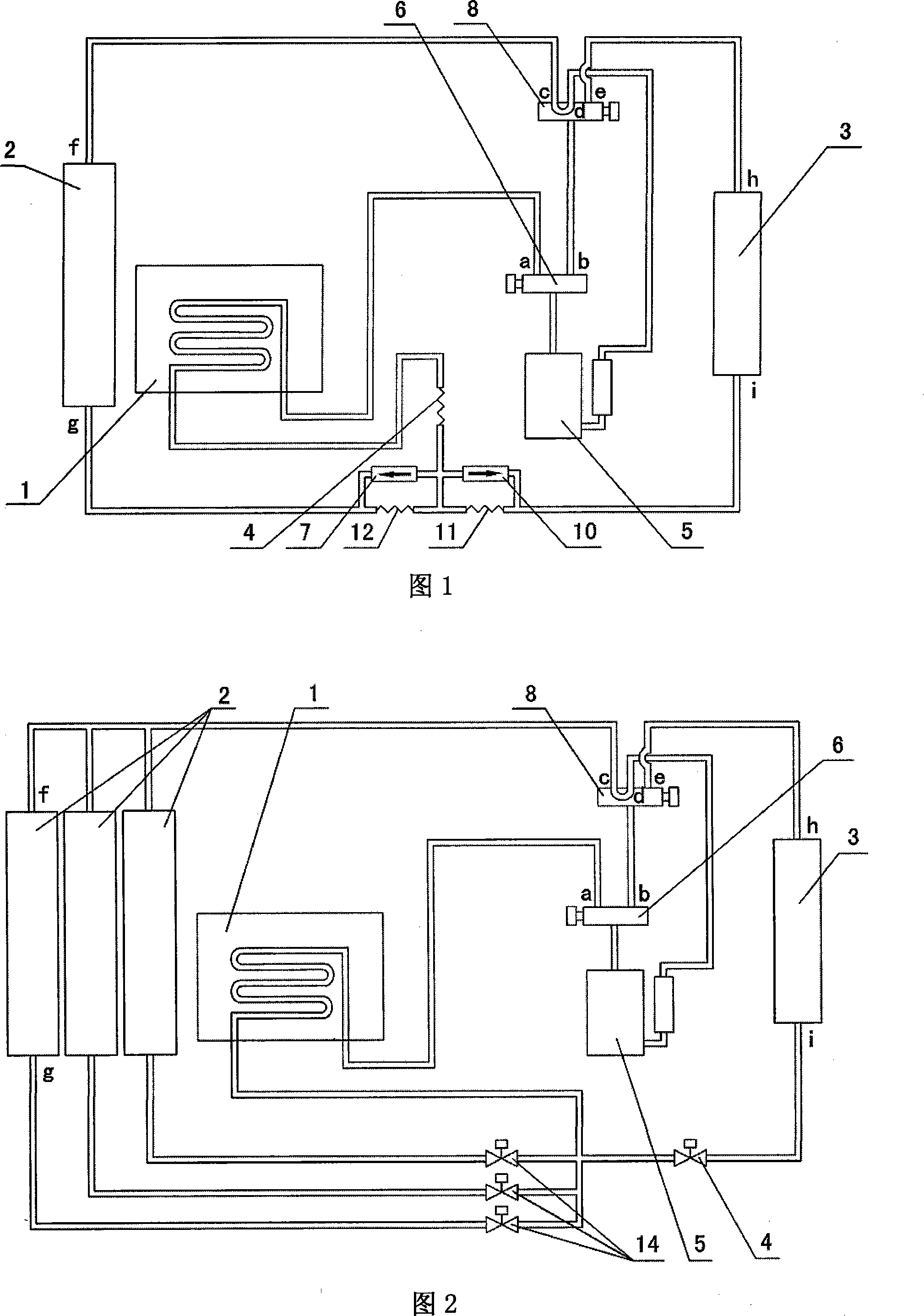

Embodiment 1

[0039] Embodiment 1 As shown in Figure 1, it includes: a water condenser 1, an inner heat exchanger unit 2, an outer heat exchanger unit 3, a throttling component 4, a compressor 5, a hot water switching valve 6, and a refrigeration check valve 7. The heating and cooling reversing valve 8, the control system 9, the heating one-way valve 10, the cooling capillary 11, the heating capillary 12 and the connecting pipeline; in the hot water air conditioning unit, the outlet of the compressor 5 is connected to the hot water switching valve The inlet of 6, the a port of the hot water switching valve 6 is connected to the inlet of the water condenser 1, the outlet of the water condenser 1 is connected to the inlet of the throttling component 4, the b port of the hot water switching valve 6 is connected to the inlet of the cooling and heating reversing valve 8, The d port of the cooling and heating reversing valve 8 is connected to the air return port of the compressor 5, the c port of ...

Embodiment 2

[0045] Embodiment 2, as shown in Figure 2, includes: a water condenser 1, an inner heat exchanger unit 2, an outer heat exchanger unit 3, a throttling component 4, a compressor 5, a hot water switching valve 6, and a heating and cooling reversing Valve 8, control system 9, cooling and heating electronic expansion valve 14 and connecting pipelines; in the hot water air conditioning unit, the outlet of compressor 5 is connected to the inlet of hot water switching valve 6, and the a port of hot water switching valve 6 is connected to water condensation The inlet of the device 1, the b port of the hot water switching valve 6 is connected to the inlet of the cooling and heating reversing valve 8, the d port of the cooling and heating reversing valve 8 is connected to the air return port of the compressor 5, and the e port of the cooling and heating reversing valve 8 is connected to the external heat exchanger The h port of unit 3, the i port of the external heat exchanger unit 3 are...

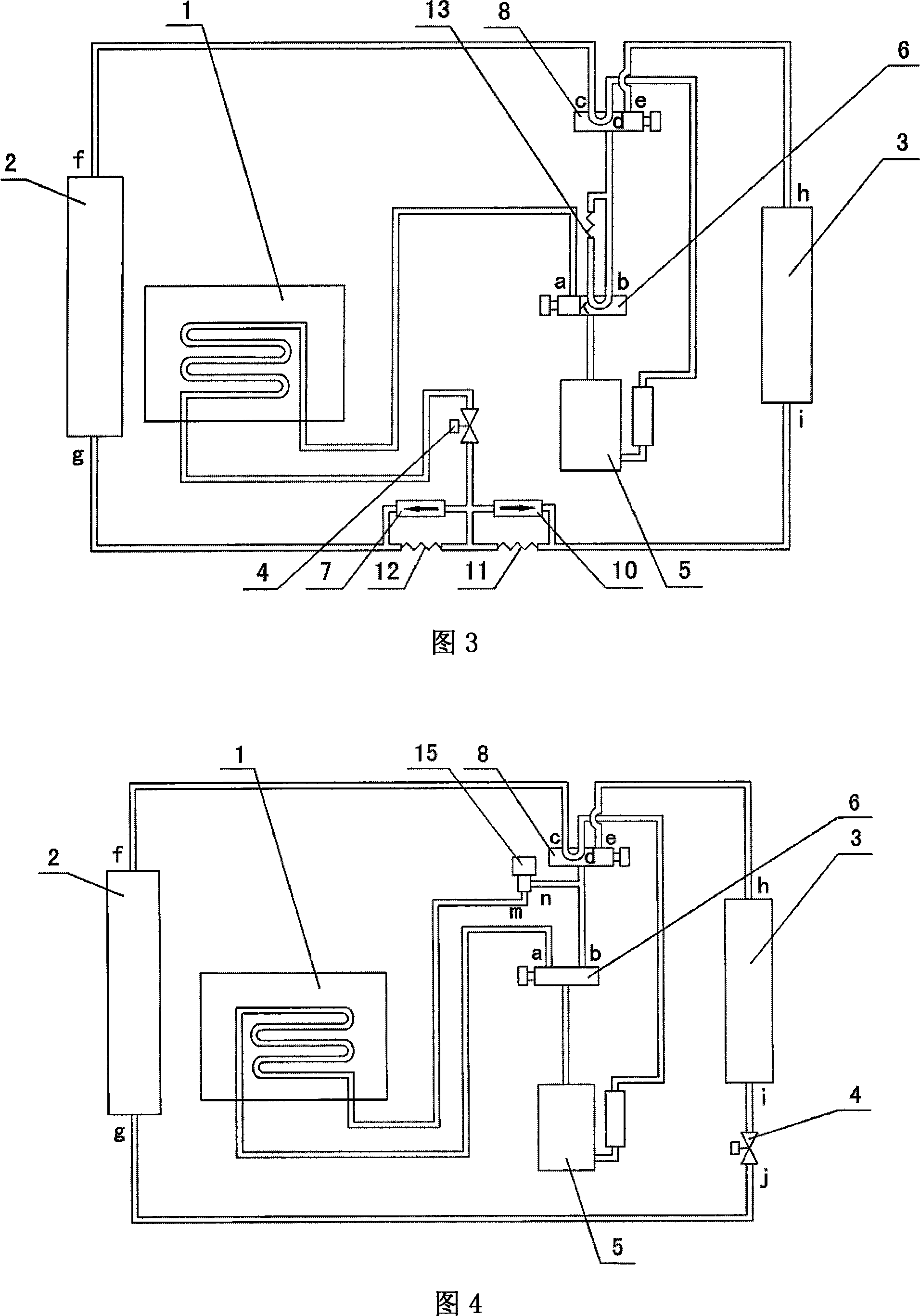

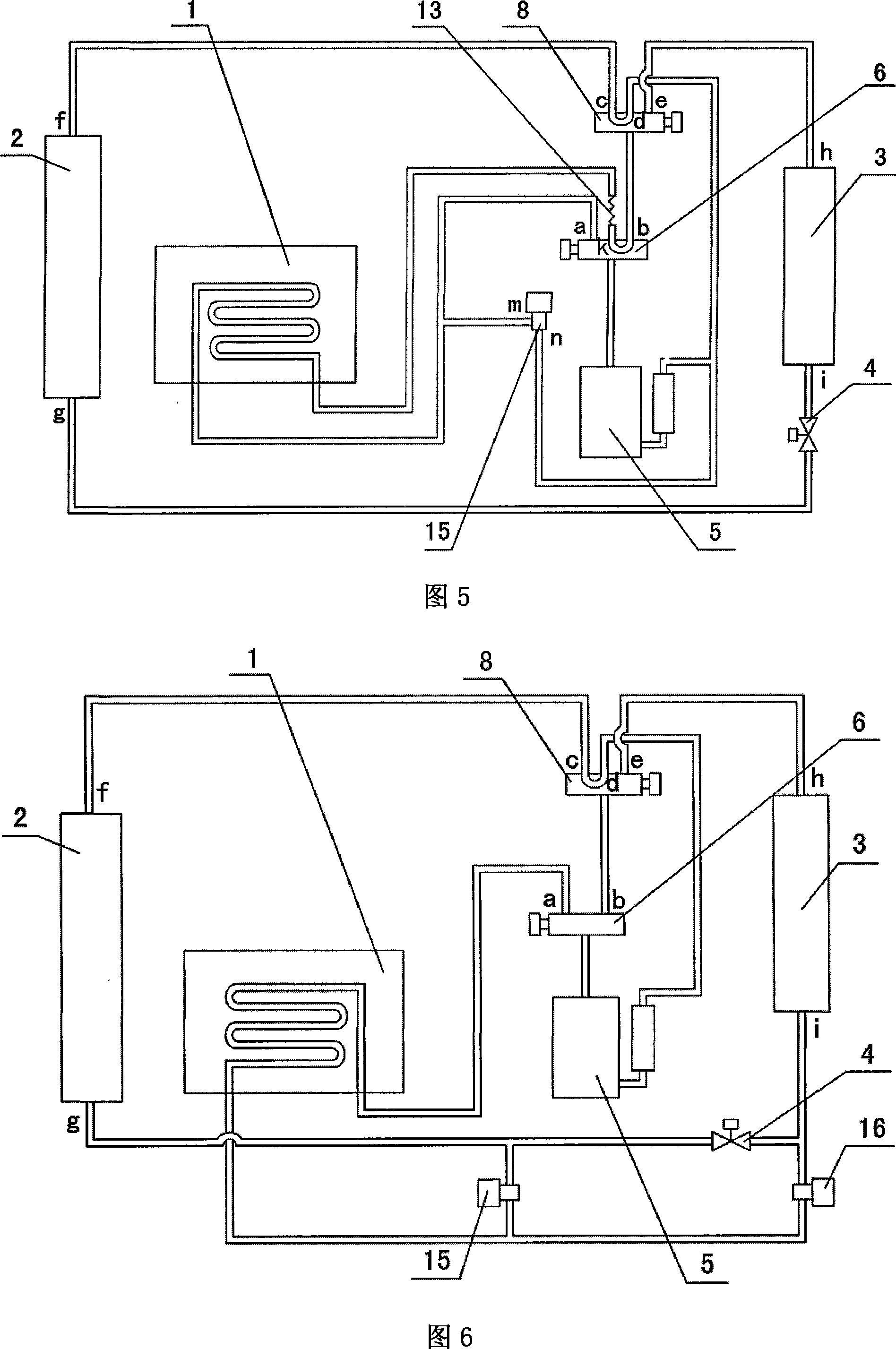

Embodiment 3

[0051]Embodiment 3, as shown in Figure 3, includes: a water condenser 1, an inner heat exchanger unit 2, an outer heat exchanger unit 3, a throttling component 4, a compressor 5, a hot water switching valve 6, and a cooling one-way Valve 7, heating and cooling reversing valve 8, control system 9, heating check valve 10, cooling capillary 11, heating capillary 12, throttling capillary 13 and connecting pipelines; The outlet is connected to the inlet of the hot water switching valve 6, the a port of the hot water switching valve 6 is connected to the inlet of the water condenser 1, the k port of the hot water switching valve 6 is connected to the throttling capillary 13, and the b port of the hot water switching valve 6 is connected to the The inlet of the cooling and heating reversing valve 8 is connected with the other port of the throttling capillary 13, the outlet of the water condenser 1 is connected to the inlet of the throttling part 4, the d port of the cooling and heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com