Compressor capable of directly gettering through impacting air suction port by spring

A technology of spring compression and suction port, which is used in liquid variable volume machinery, parts of pumping devices for elastic fluids, and parts of rotary piston type/swing piston type pumps, etc., which can solve the problem of easy deformation of bellows. Aging, affecting the efficiency of the whole machine, short service life and other problems, to avoid the hidden danger of fracture quality, reduce startup noise, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

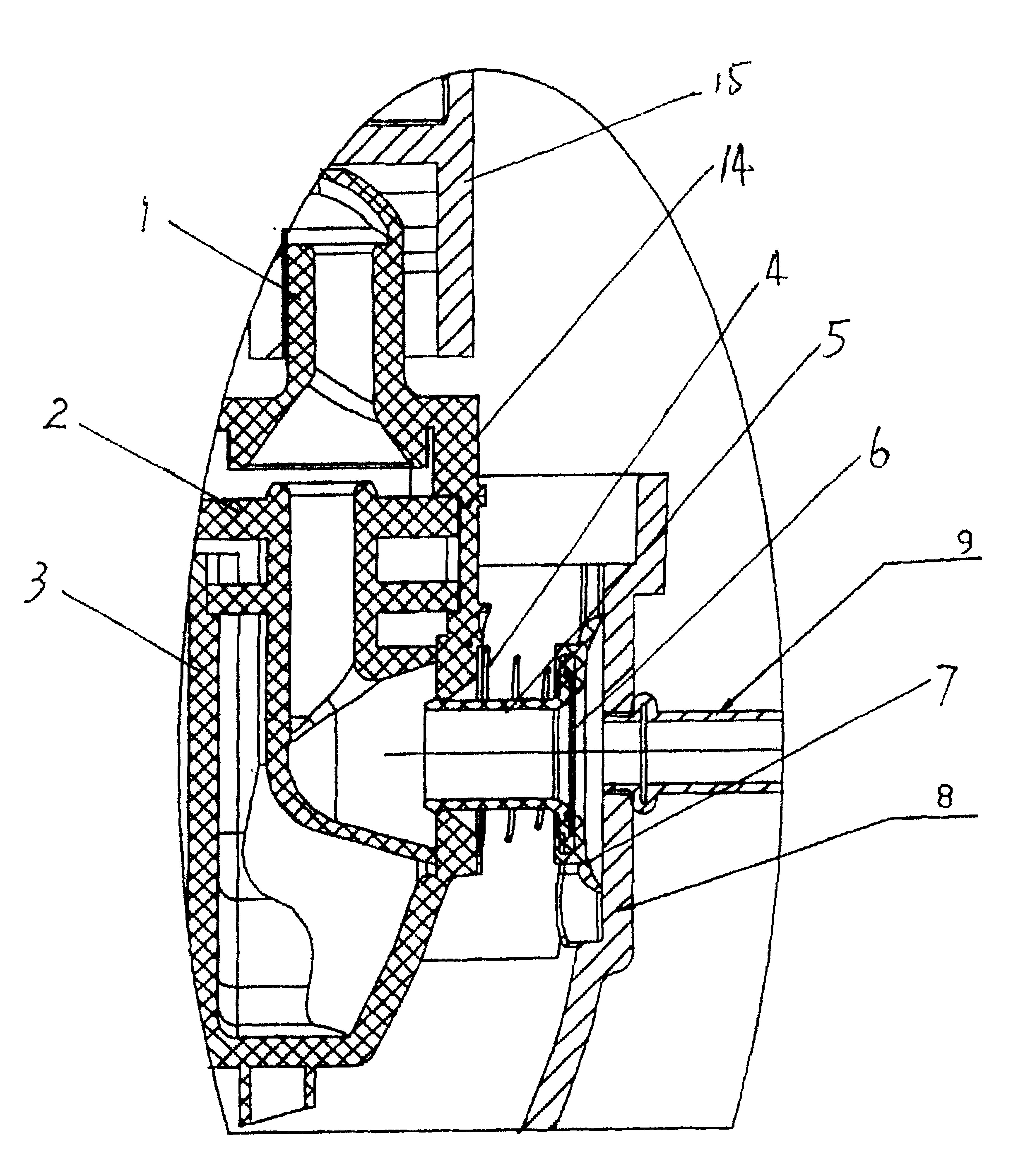

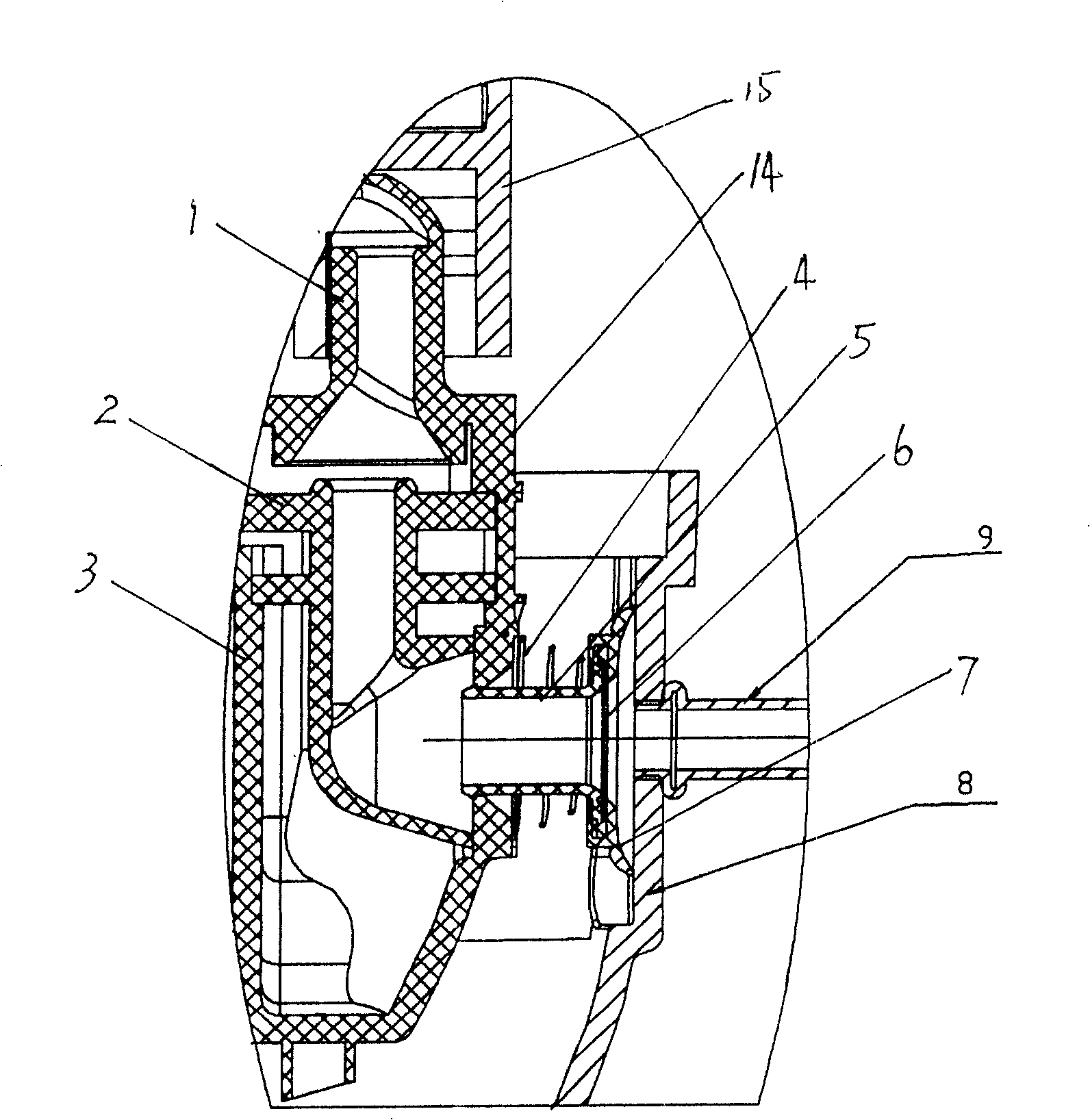

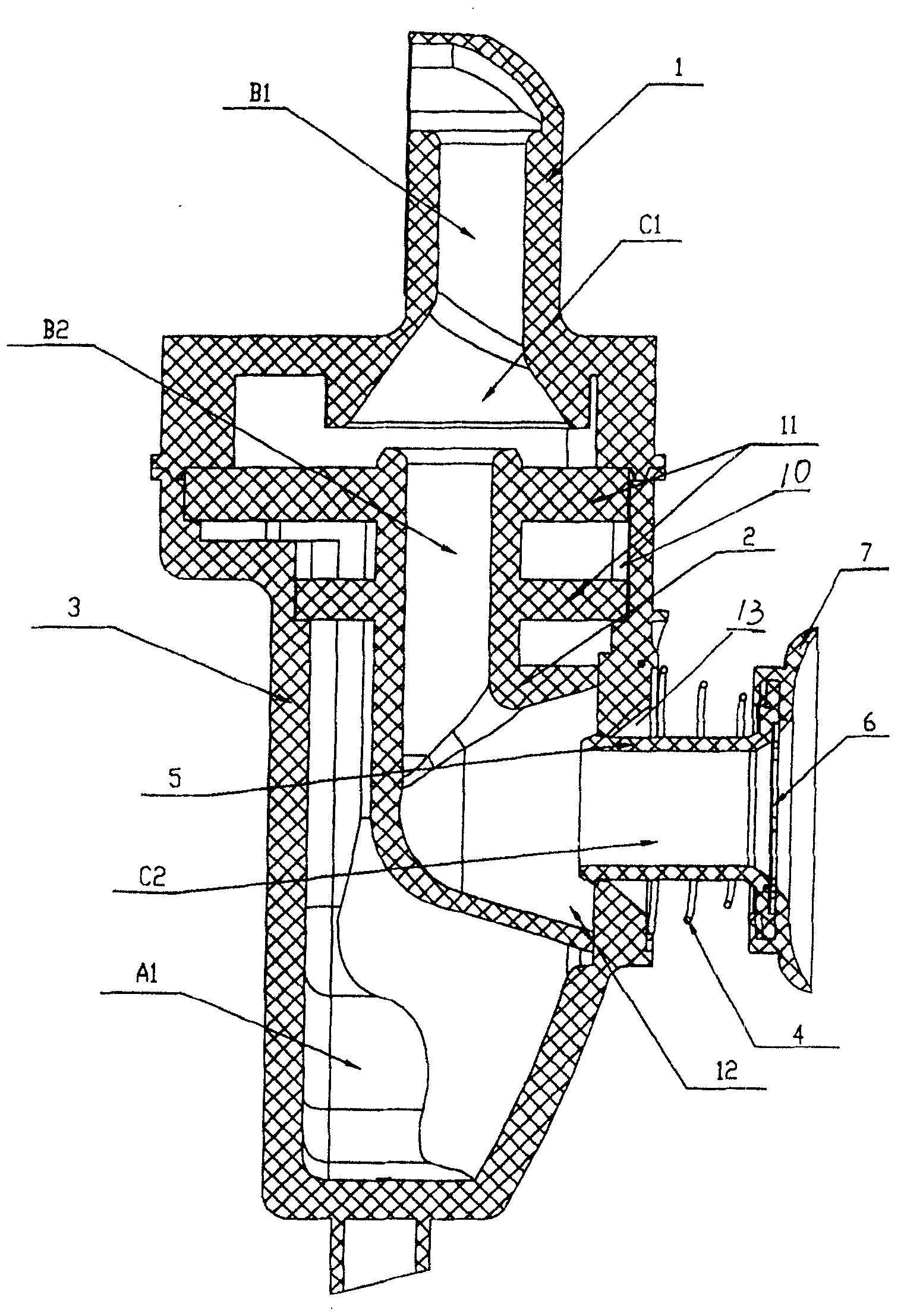

[0020] Referring to Fig. 1, the present invention has housing 8, and compressor movement assembly 15 is housed in housing 8, includes a muffler chamber 14, and the outer wall of housing 8 is connected with suction pipe 9, and the pipe of suction pipe 9 The mouth opens into the housing 8 and faces the suction port 13 of the muffler cavity 14 . Especially in the utility model, a connecting pipe 5 is used to connect the mouth of the suction pipe 9 and the suction port 13 of the muffler cavity. The right end of the connecting pipe 5 is a flanging mouth, on which a Sealed collection port 7, the sealed collection port 7 covers the mouth of the suction pipe 9, and is closely attached to the inner wall of the housing 8; the left end of the connecting pipe 5 is inserted into the suction port 13 of the muffler chamber (move-fit connection), The docking of connecting pipe 5 and the suction port 13 of muffler cavity can also design a shorter suction pipe on suction port 13, and connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com