Cutter

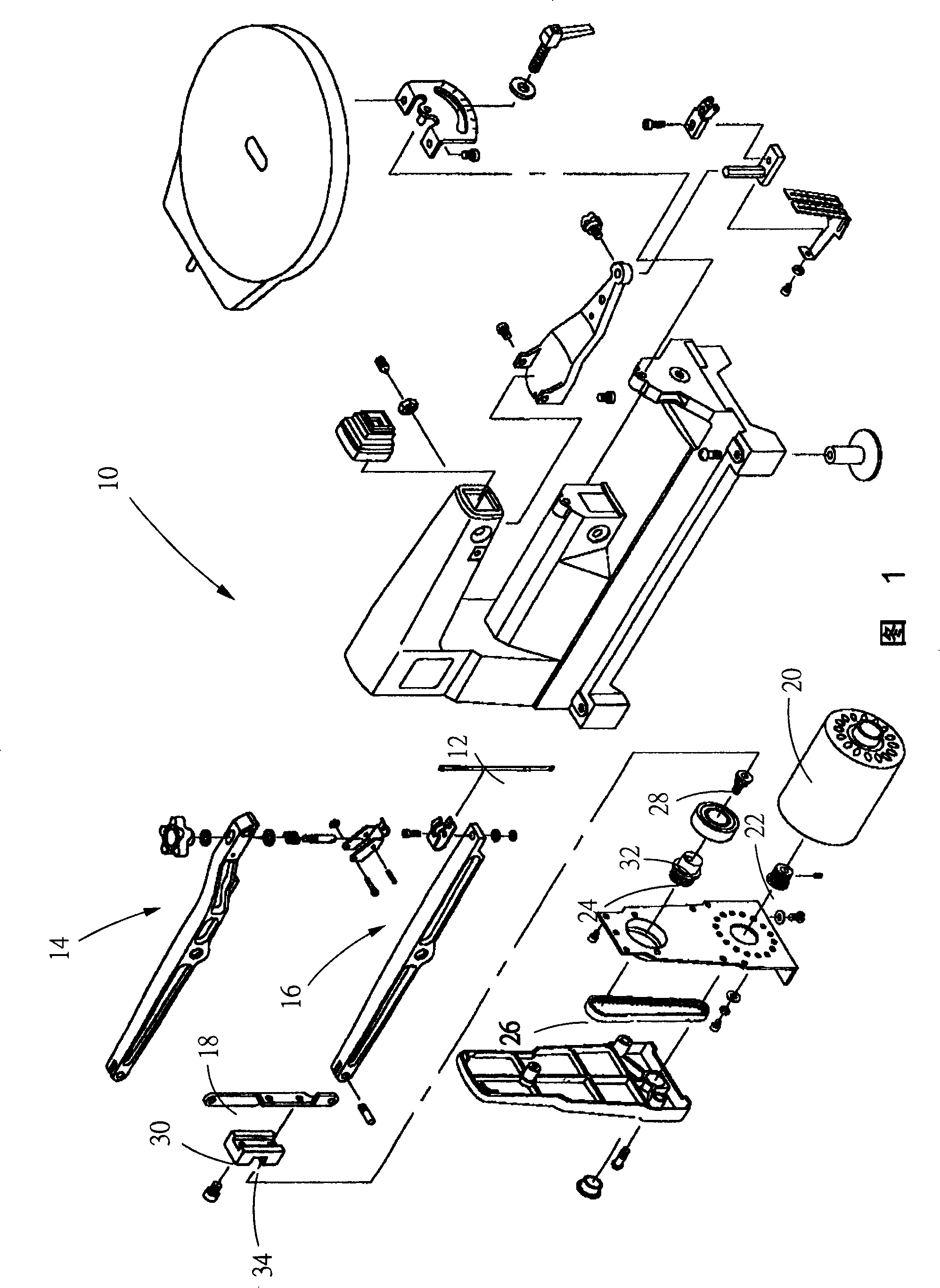

A cutting machine and base technology, applied in metal processing and other directions, can solve the problems of operator inconvenience, vibration and noise of the wire saw machine 10, and troubles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

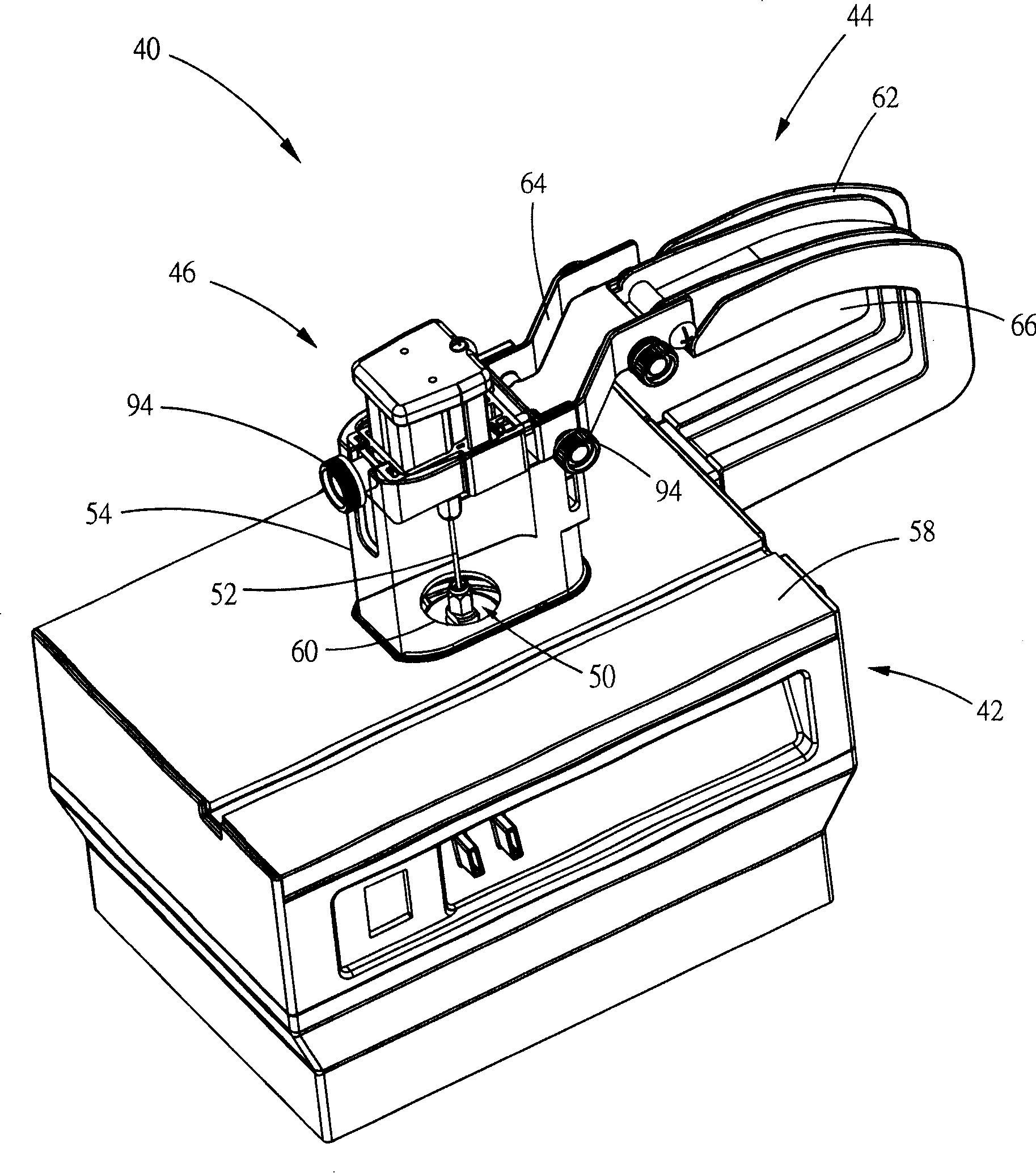

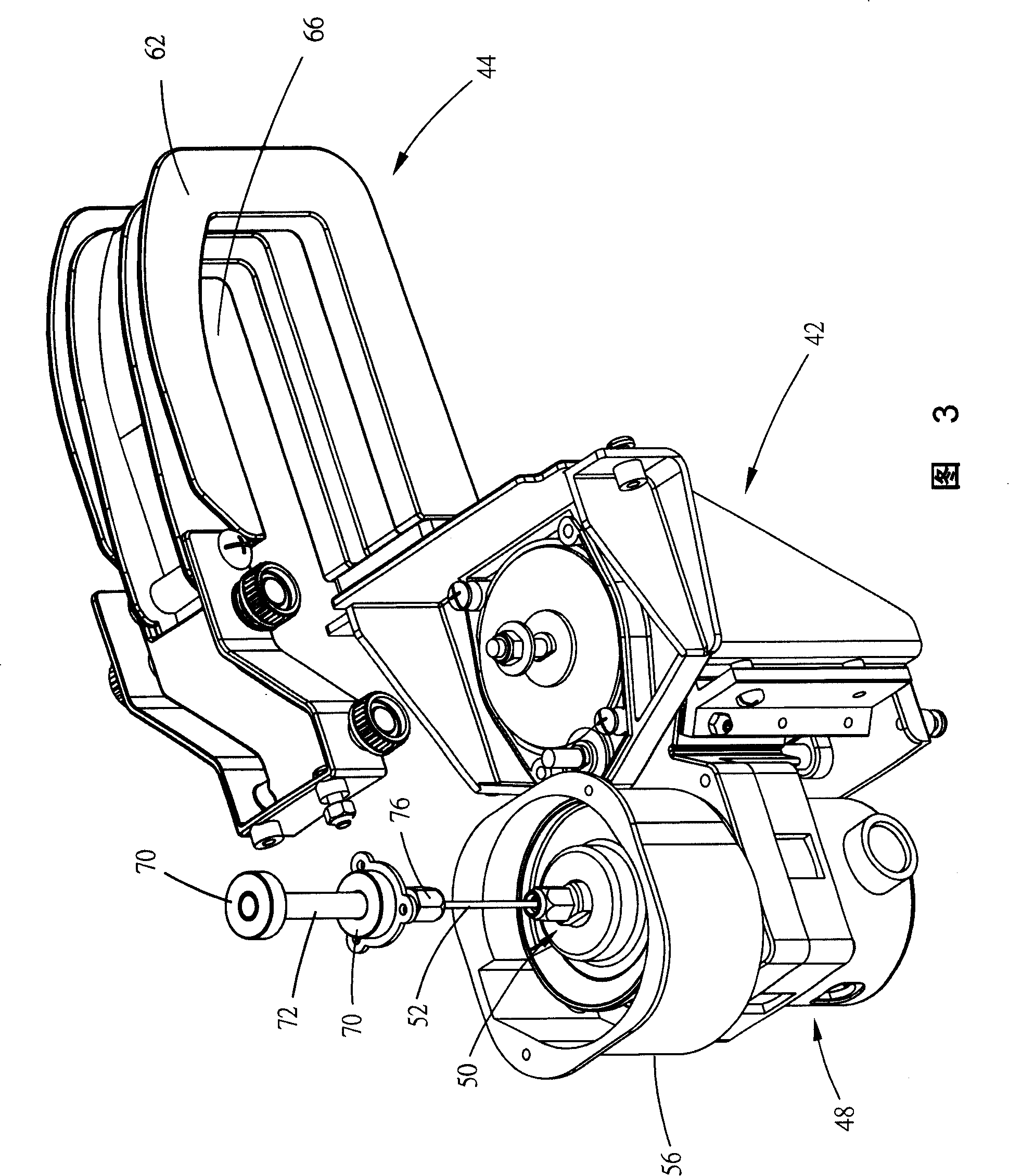

[0013] see figure 2 and Figure 3, figure 2 It is a perspective view of the cutting machine of the present invention, and FIG. 3 is an internal structure diagram of the cutting machine of the present invention. The present invention provides a cutting machine 40. In this embodiment, the cutting machine 40 includes a base 42, an arm 44, a first clamping device 46, a driving device 48, a second clamping device 50, A hob 52 , a limiting member 54 and a dust cover 56 .

[0014] see figure 2 , the top of the base 42 is a working platform 58, the working platform 58 is used to carry a workpiece (not shown) to be cut by the cutting machine 40, and a hole 60 is opened at about its center.

[0015] Support arm 44 has a bow-shaped body 62 and a pivoting part 64, and bow-shaped body 62 forms a throat space 66, can extend wherein when this workpiece changes position on the working platform 58, one end of bow-shaped body 62 is fixed. Connected to one side of the top of the base 42, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com