Duplicating cutting machine

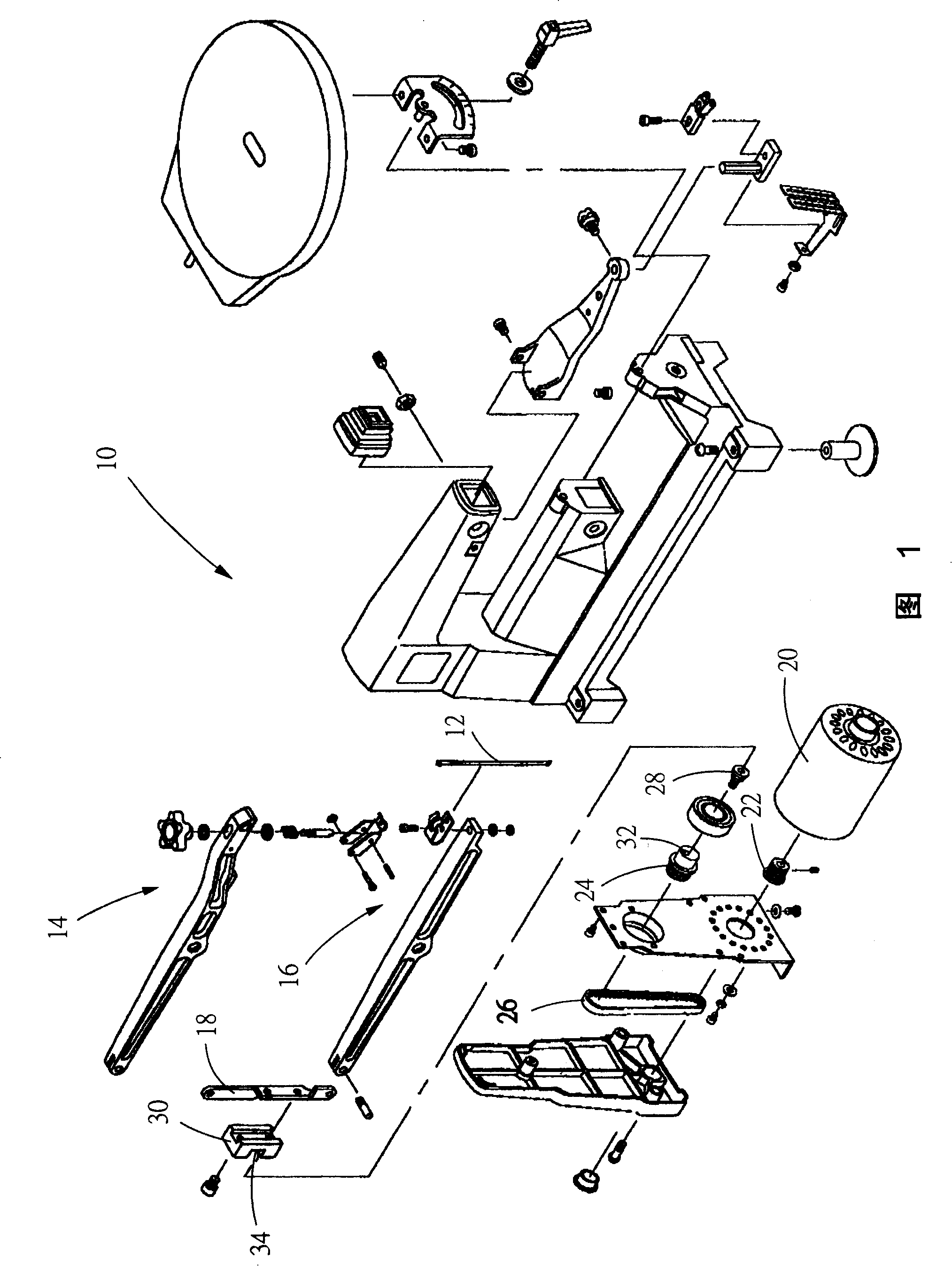

A cutting machine and sliding technology, applied in the direction of copying process control system, manufacturing tools, metal processing, etc., can solve the problems of operator inconvenience, vibration, noise and trouble of wire saw machine 10

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

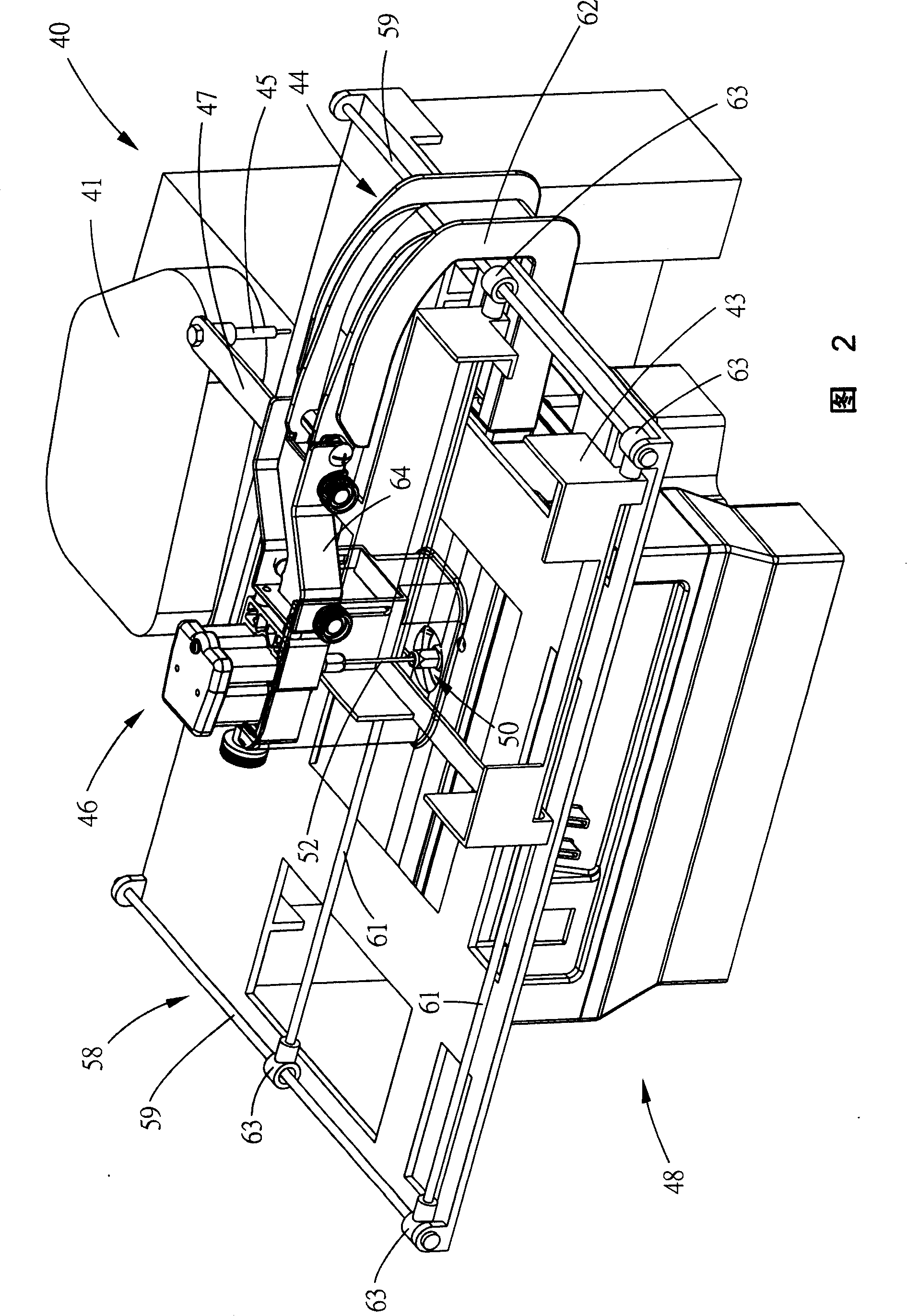

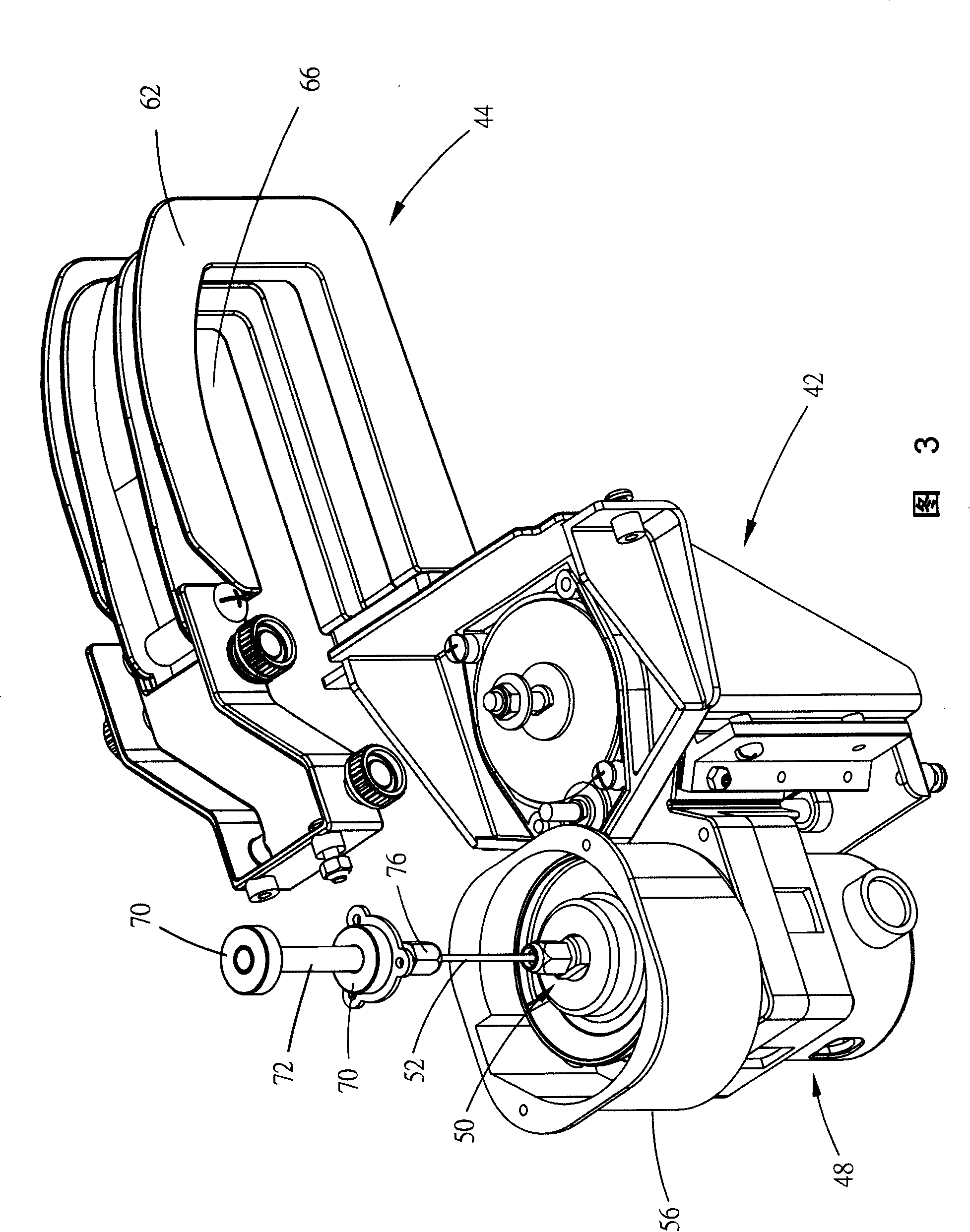

[0011] Please refer to FIG. 2 and FIG. 3 , FIG. 2 is a perspective view of the duplicating cutting machine of the present invention, and FIG. 3 is an internal structure diagram of the duplicating cutting machine of the present invention. The present invention provides a replica cutting machine 40 for cutting a workpiece according to a pattern 41 separate from the workpiece. The pattern 41 can be represented by a sample or drawn on a plane. In this embodiment, the replica cutting machine 40 includes A base 42, a storage frame 43, an arm 44, a pointer 45, a first clamping device 46, a connecting rod 47, a driving device 48, a second clamping device 50, a hob 52, A limiting member 54 and a dust collecting cover 56 .

[0012] Referring to Fig. 2, the storage frame 43 is used to accommodate the workpiece; the top of the base 42 has a working platform 58, and the working platform 58 has two fixed rods 59 and two moving rods 61, and the two fixed rods 59 are respectively fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com