Box-shaped floating type dock gate with open bottomtank

A bilge and floating technology, applied in dry docks, ships, transportation and packaging, etc., can solve the problems of large displacement of box-shaped floating dock doors, difficult removal of sediment deposits, and poor water discharge from tidal chambers, etc., to improve The effect of sinking and floating stability, saving investment and daily equipment operation and maintenance costs, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

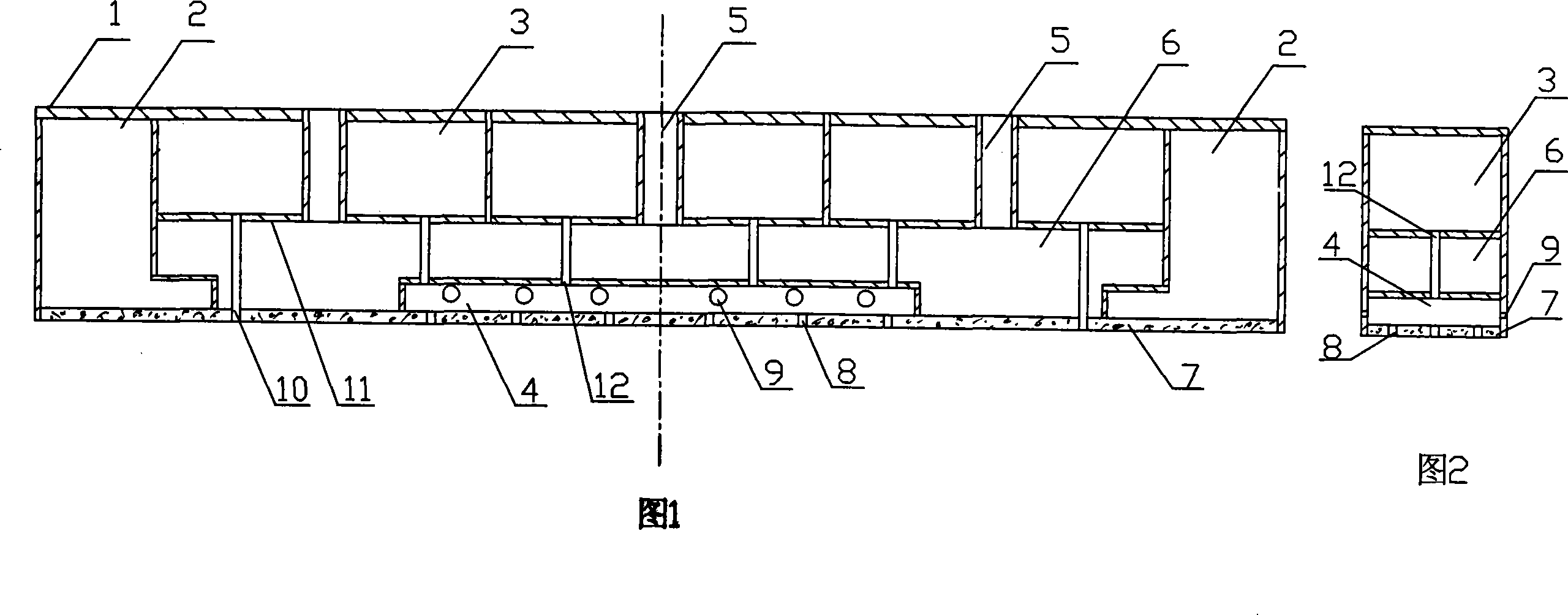

[0018] Referring to accompanying drawings 1-2, the present invention comprises door body 1 and ballast water tank 2, tidal chamber 3, bilge tank 4, pump valve cabin 6 that are arranged in door body 1, and door body 1 is the box body of rectangle, and it It is assembled and welded by panels, bottom plates and side plates. The bottom plate of the door body 1 is provided with solid ballast 7 of cast-in-place heavy aggregate concrete. The bottom surface of the solid ballast 7 is the same size as the bottom plate of the door body 1. Depending on the displacement, the two ends of the door body 1 and the solid ballast 7 are symmetrically provided with a ballast water tank 2 with an "L" shape in cross-section; the solid ballast 7 is in the form of a water collection well in the ballast water tank 2. There is a deck 11 between the two ballast water tanks 2. The deck 11 divides the door body 1 into upper and lower layers. The upper layer is divided into several tidal tanks 3 by a waterti...

Embodiment 2

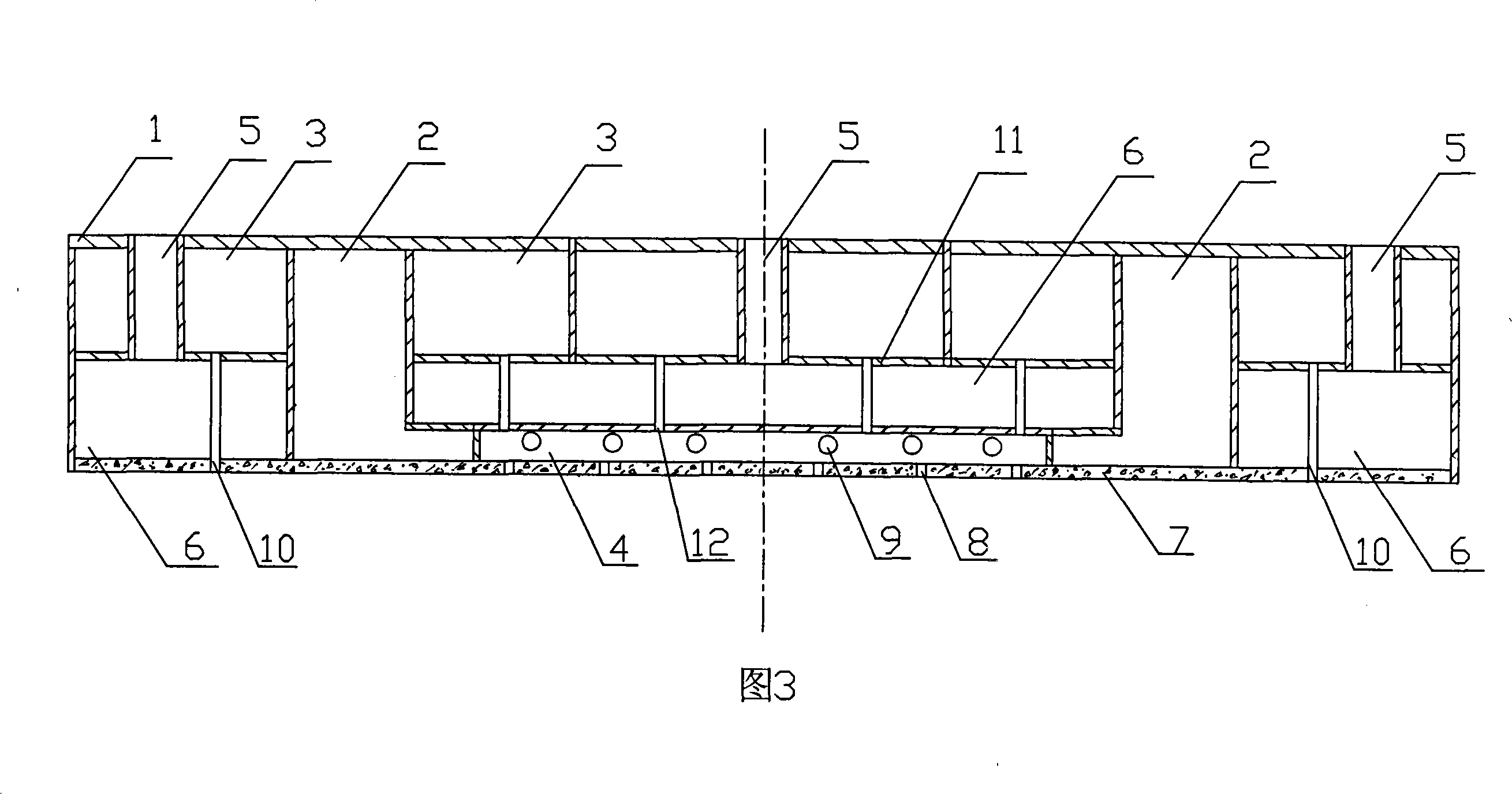

[0020] Referring to accompanying drawing 3, the present invention comprises door body 1 and the ballast water tank 2 that is arranged on door body 1, tidal tank 3, bilge 4, pump valve cabin 6, door body 1 is the box body of rectangle, and it is made of panel , bottom plate and side plate are assembled and welded. The bottom plate of the door body 1 is provided with solid ballast 7 of cast-in-place heavy aggregate concrete. The bottom surface of the solid ballast 7 is the same size as the bottom plate of the door body 1. Fixed, the middle part of the door body 1 and the solid ballast 7 are provided with a bilge 4, and the two ends of the bilge 4 and the solid ballast 7 are symmetrically provided with a ballast water tank 2 with an "L" shape in section, and the solid ballast 7 The ballast water tank 2 is in the form of a water collection well, and a deck 11 is provided between the two ballast water tanks 2. The deck 11 divides the door body 1 into upper and lower layers, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com