Exhaust structure of vacuum cleaner

A technology for vacuum cleaners and discharge pipes, applied in cleaning equipment, suction filters, vacuum cleaners, etc., can solve problems such as air leakage, increased shielding force at the suction opening, and reduced vacuum force, so as to prevent air leakage and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

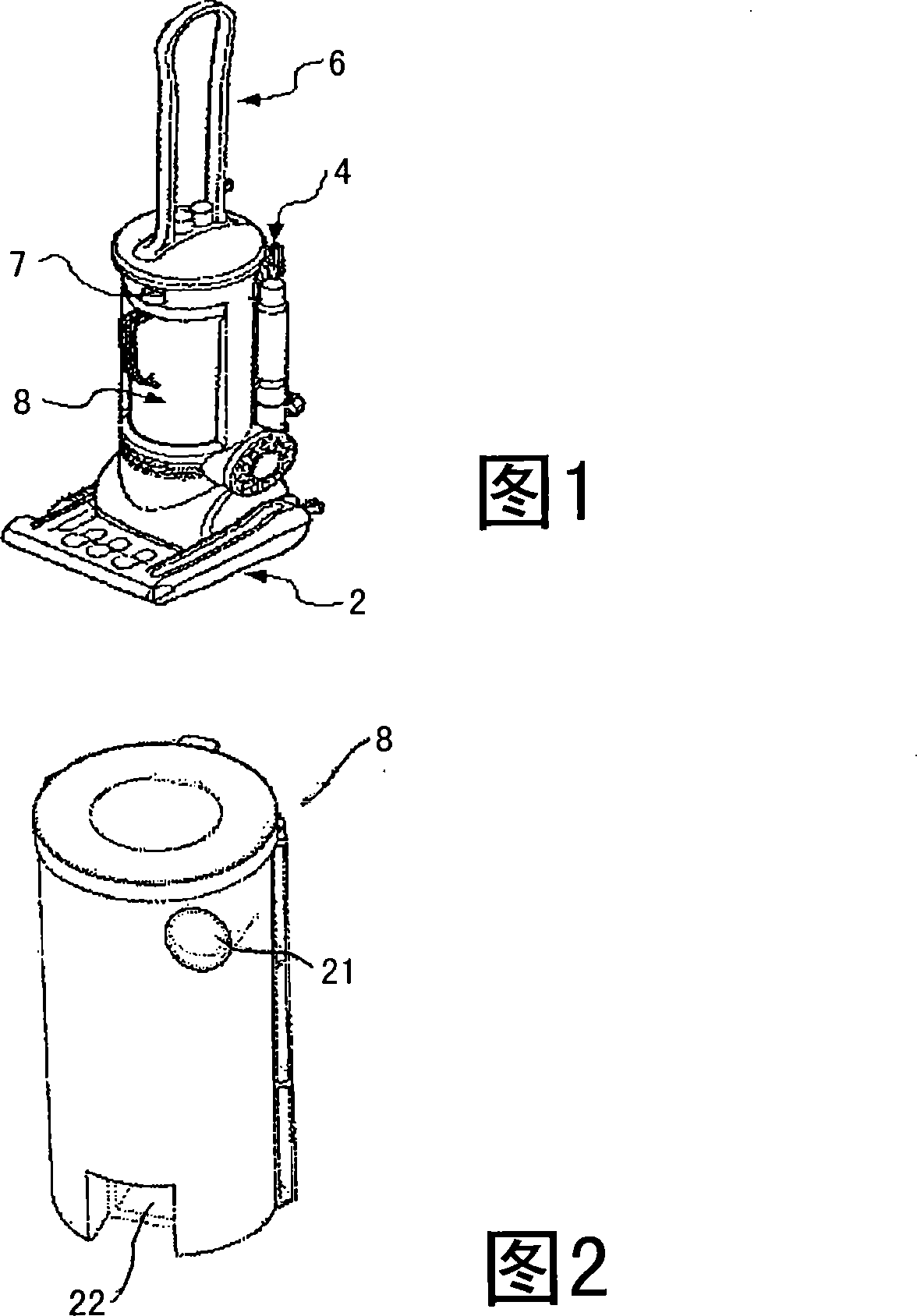

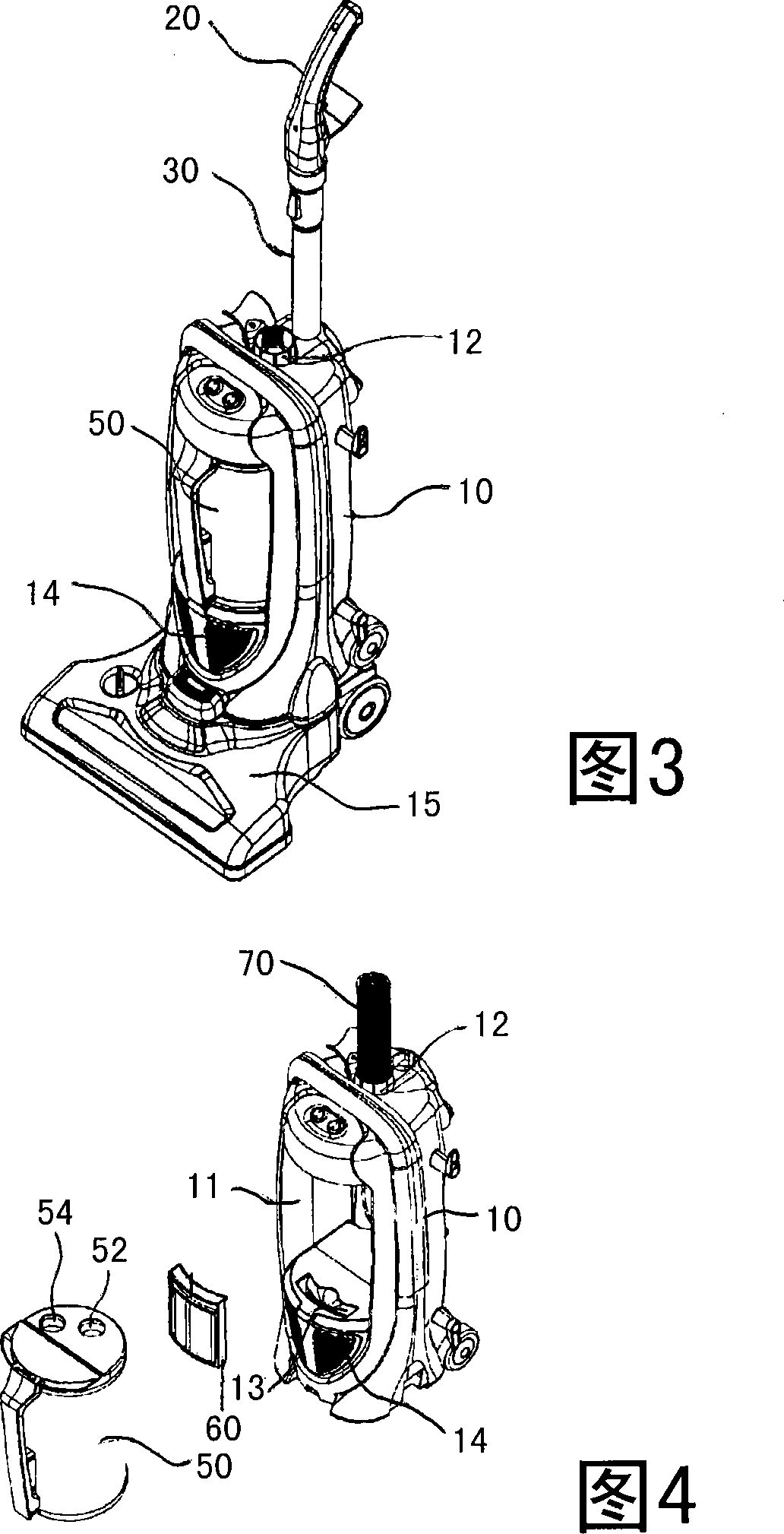

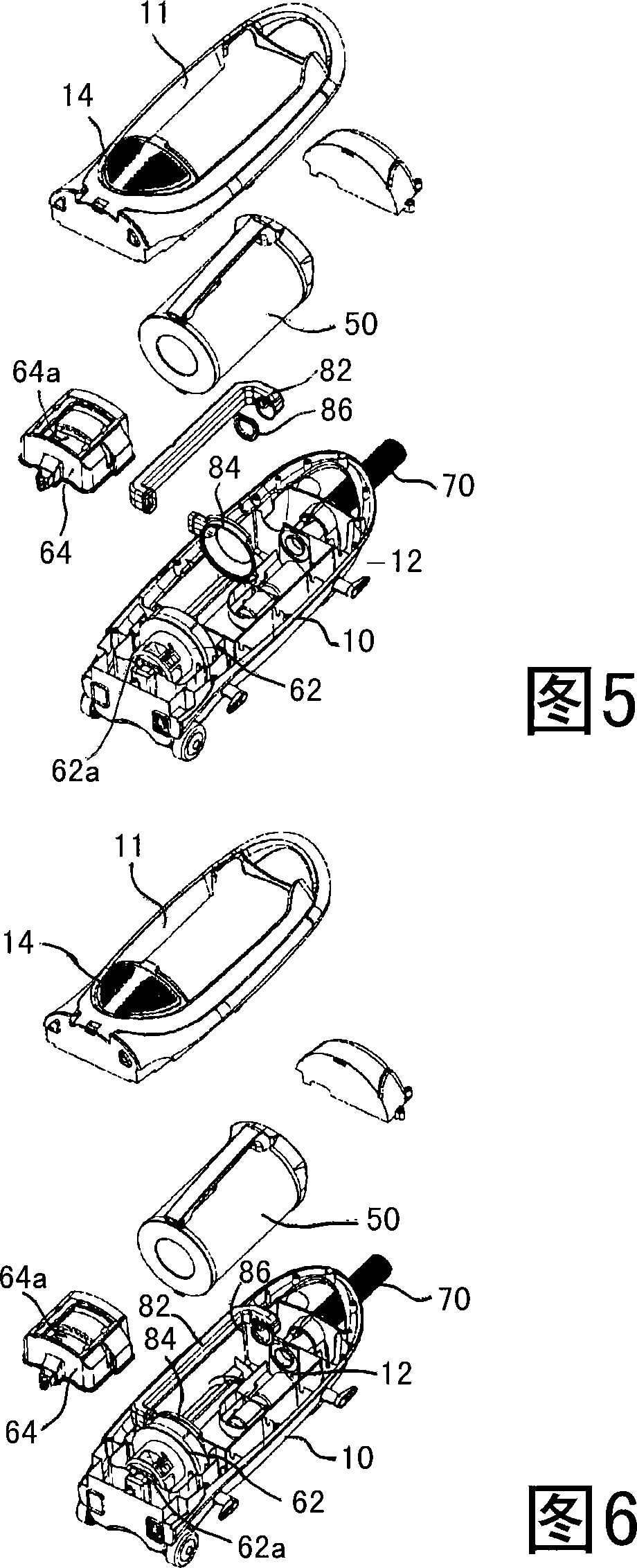

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] 3 is a perspective view illustrating a vacuum cleaner according to the present invention; and FIG. 4 is an exploded perspective view illustrating a dust collector of the vacuum cleaner according to the present invention.

[0039] The vacuum cleaner according to the present invention includes: a main body 10 having a predetermined space therein and having a suction port 12 and a discharge port 14 thereon; a suction unit 15 detachably mounted on the lower side of the main body 10 to The main body 10 is made upright, and has a dust collection port (not shown) and a discharge opening 18; a suction hose 70, located between the suction port 12 and the discharge opening 18; an extension pipe 30, detachably installed on the main body 10 , and the interior is hollow so as to define the flow channel along which the dust is sucked; the handle 20 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com