Abnormality detection device for step and passenger conveyor

An anomaly detection and cascade technology, which is applied in escalators, transportation and packaging, etc., can solve the problems of increased cost and failure to detect the damage of the front wheel roller 14, and achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] Hereinafter, embodiments of a step abnormality detection device and a passenger conveyor having the step abnormality detection device according to the present invention will be described with reference to the drawings. The drawings are not reduced or enlarged according to the scale, but only show the outline of the embodiment. And, it is not a diagram intended to illustrate a detailed part of the configuration of the embodiment. These figures can be arbitrarily determined by those skilled in the art from the information presented here.

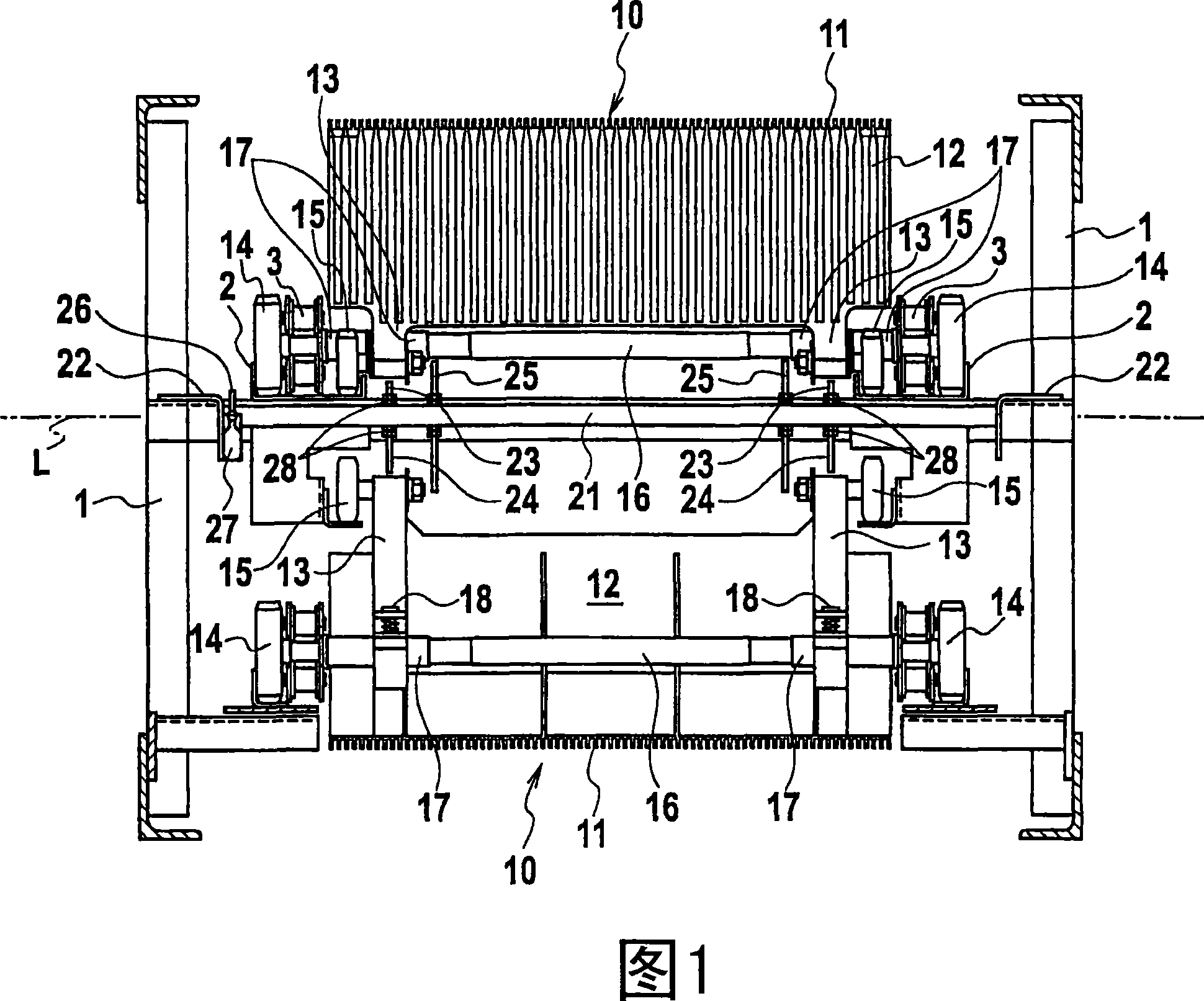

[0022] Fig. 3 is a front cross-sectional view showing the vicinity of a landing of a truss of an escalator which is an example of a passenger conveyor provided with a step abnormality detection device according to the present invention. In FIG. 3 , the upper half of the dashed-dotted line L indicates the outbound route, and the lower half indicates the return route.

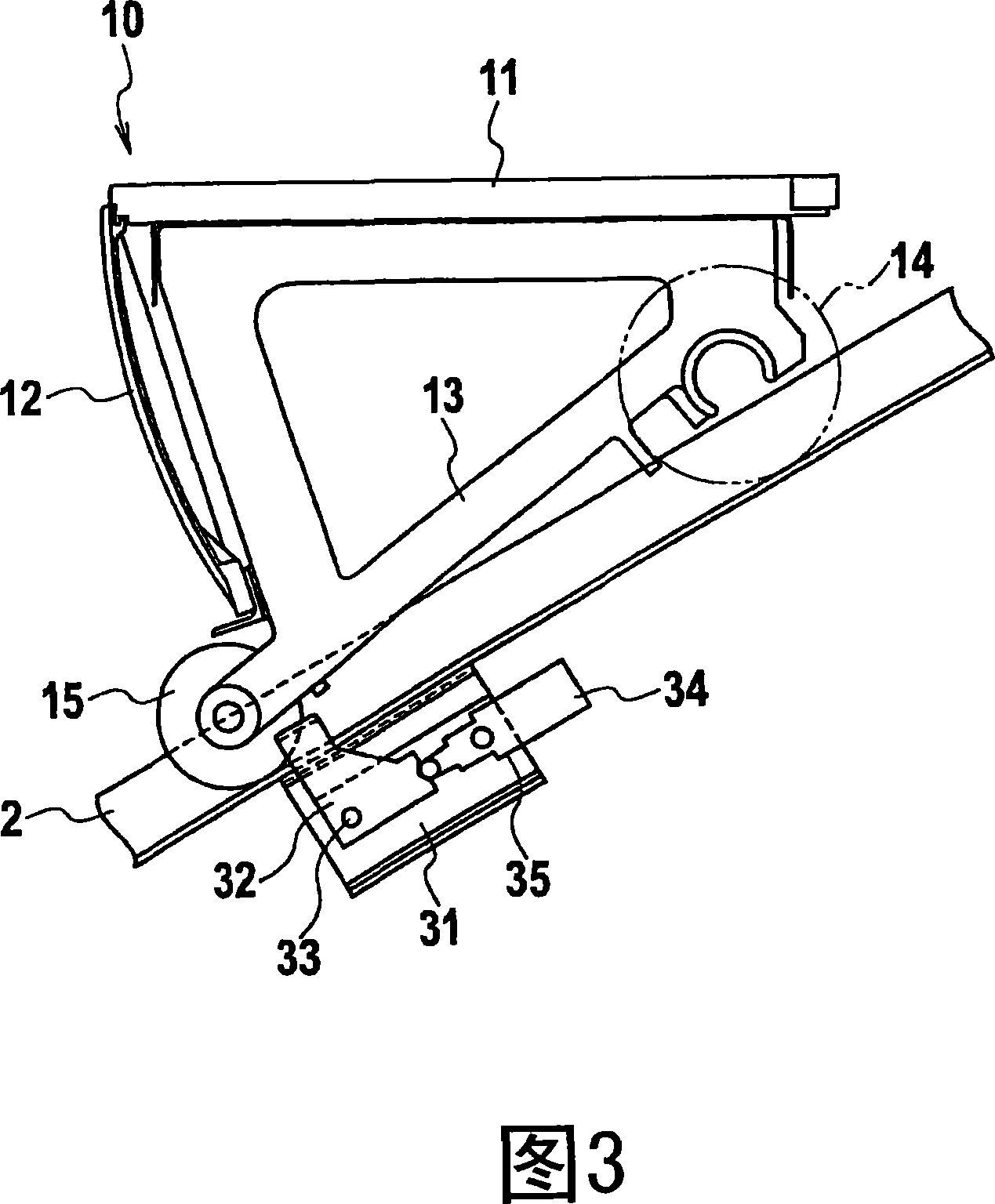

[0023] The steps 10 on which passengers ride have steps 11 and rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com