High performance overhead valvetrain assembly

An overhead valve, high-performance technology, applied in the direction of valve devices, mechanical equipment, engine components, etc., can solve problems such as the rocker arm is out of position, the rocker arm is out of the expected operating position, and the installation configuration is not satisfactory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

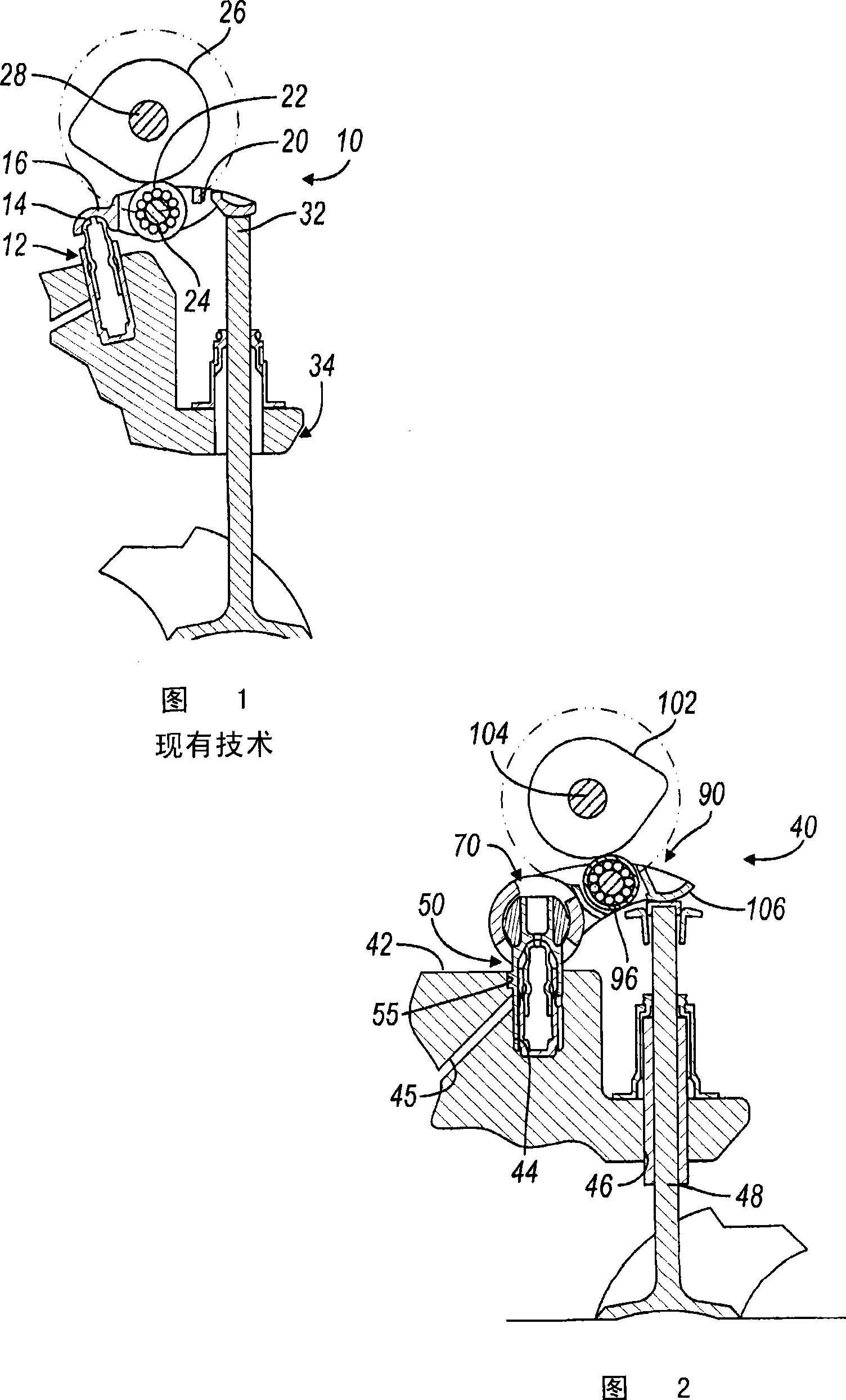

[0019] Referring now to FIG. 1 , a typical prior art valve train is shown and generally designated by the reference numeral 10 . The prior art valve train 10 includes a hydraulic lash adjuster 12 having a hemispherical end portion 14 received in a complementary hemispherical socket 16 provided at one end of a rocker arm 20 . Rocker arm 20 also includes a cam follower 22 supported by antifriction bearings such as roller or ball bearings 24 . According to a conventional embodiment, the cam follower 22 engages a cam 26 on an overhead camshaft 28 . Stem portion 32 of valve 34 is located at the end of rocker arm 20 opposite lash adjuster 12 and contacts rocker arm 20 . It should be understood that in this prior art valve configuration, the rocker arm 20 is primarily constrained within its run location. This mounting configuration limits the speed of the engine and limits valve travel or lift.

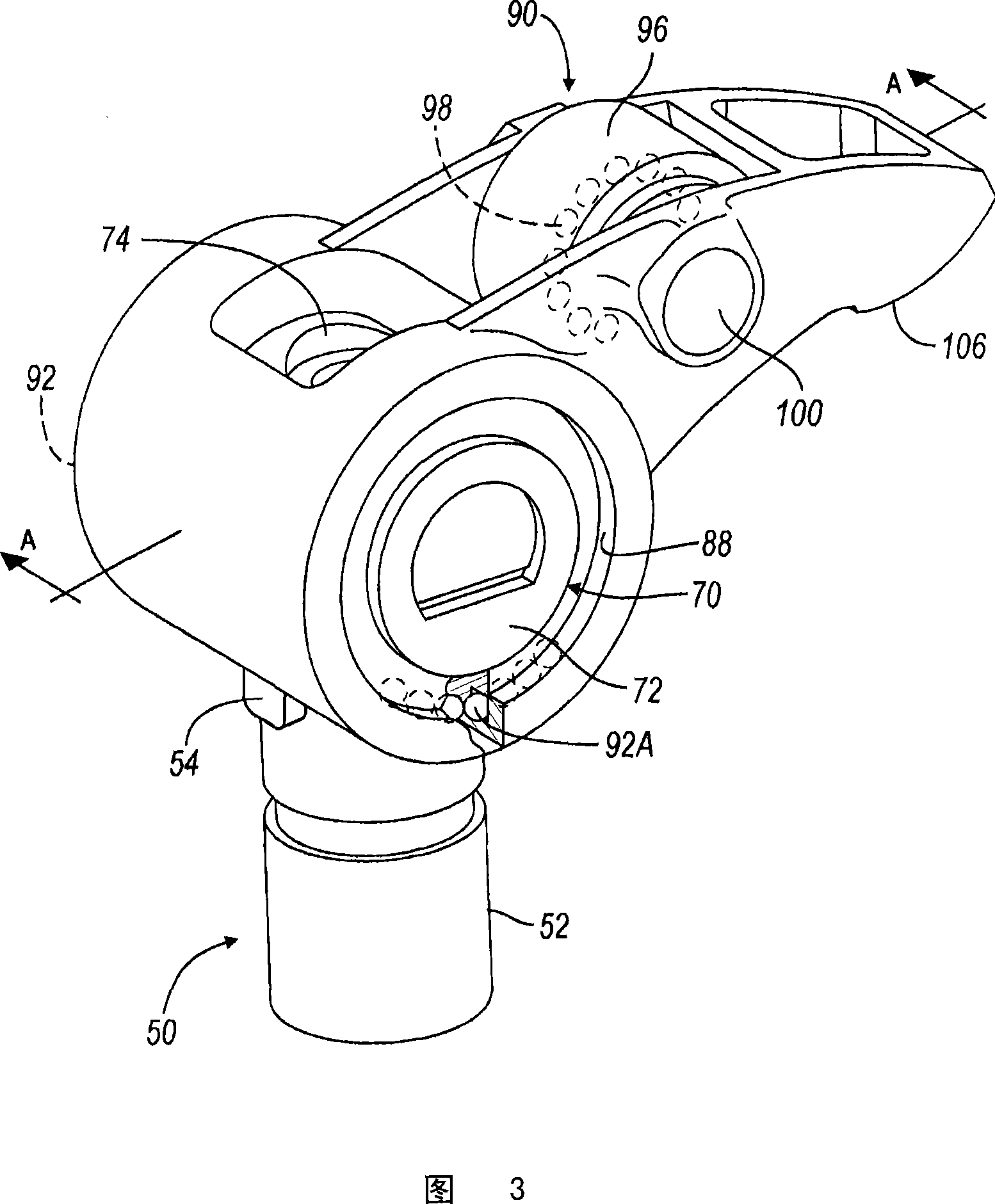

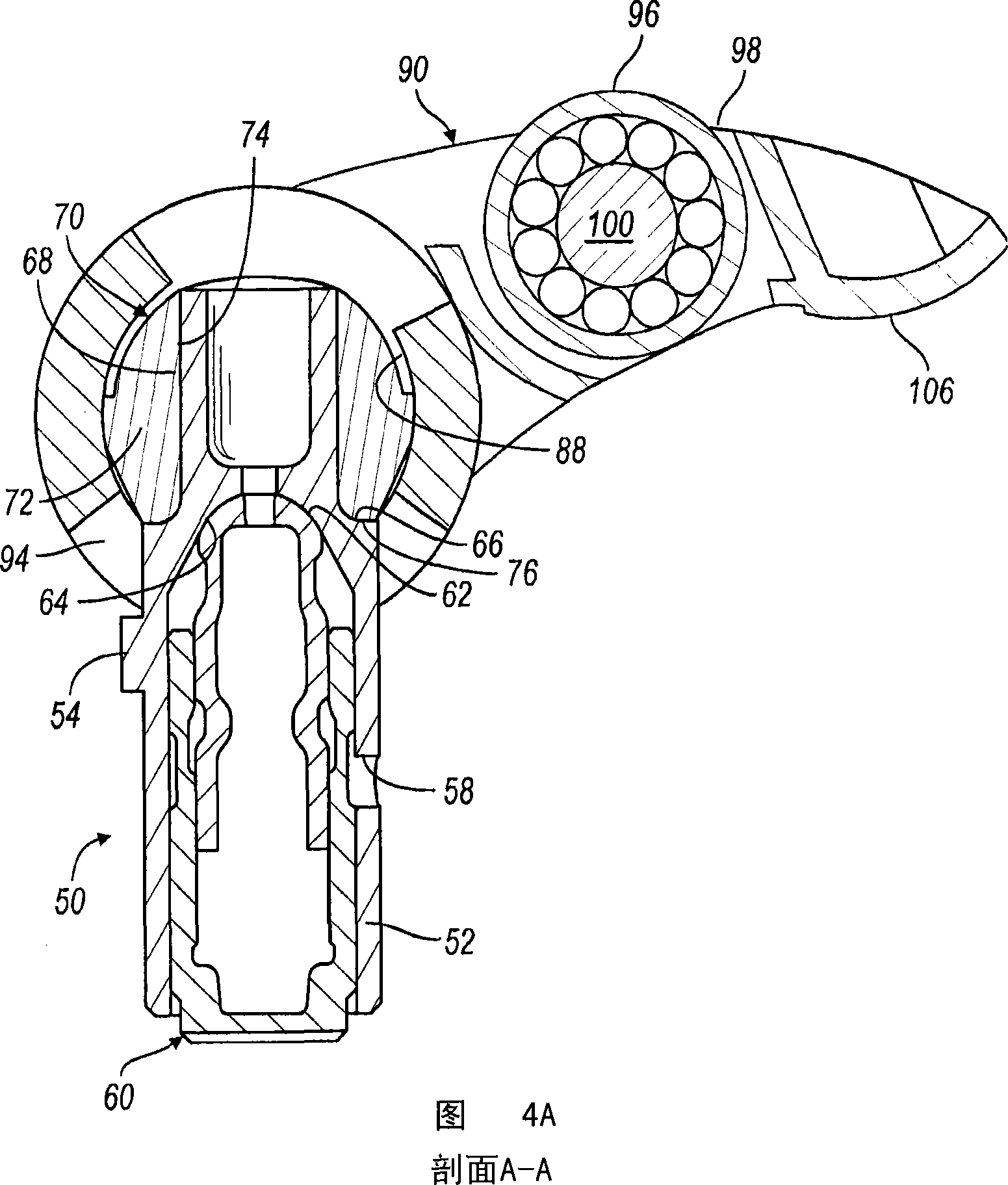

[0020] Referring now to FIG. 2 , a first embodiment of an overhead valve train 40 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com