Device for sucking ray flower of carding machine

A technology of carding machine and air suction device, which is used in deburring devices, fiber processing, textiles and papermaking, etc., can solve the problems of long downtime, high cleaning work intensity, and inability to operate normally, and achieve the effect of ensuring work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

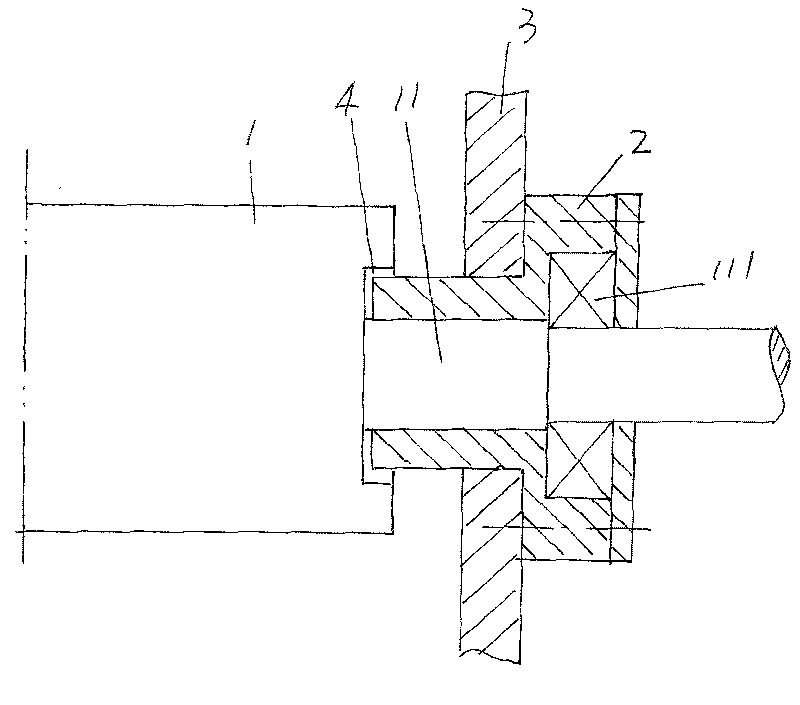

Embodiment 1

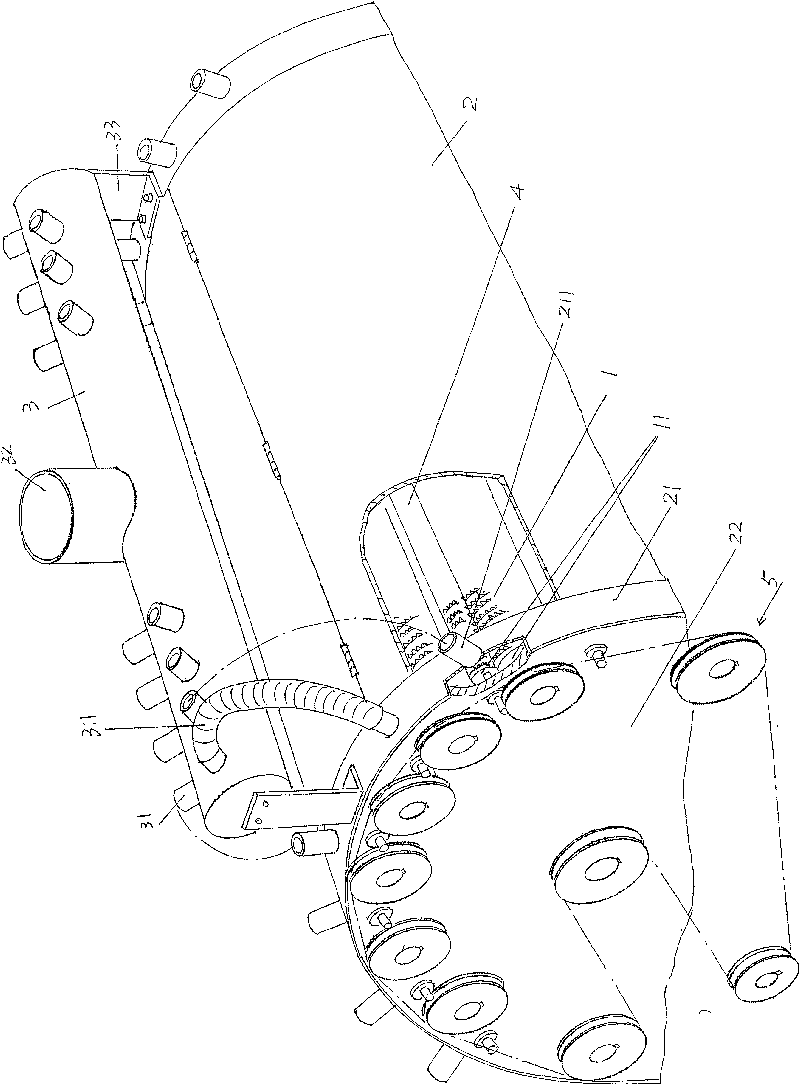

[0017] please see figure 2 , provides a specific embodiment in which the edge suction device is indirectly arranged on the roller cover 2 of the carding machine, the air collecting pipe 3 is arranged along the length direction of the roller cover 2, specifically: the air collecting pipe The two ends of 3 are fixed with the edge banding plates 21 at the two ends of the roller cover 2. A group of suction nozzles 31 (also called suction nozzles) are respectively extended at both ends of the air collecting pipe 3, and the suction nozzles 31 can directly extend to the upper part of the end of the carding cylinder 1; A connecting pipe 311 transitions, one end of the connecting pipe 311 is connected to the suction nozzle 31, and the other end of the connecting pipe 311 is connected to the corresponding suction nozzle 211 (also called the corresponding suction nozzle) extending on the edge sealing plate 21. The position of the suction nozzle 211 corresponds exactly to the top of the...

Embodiment 2

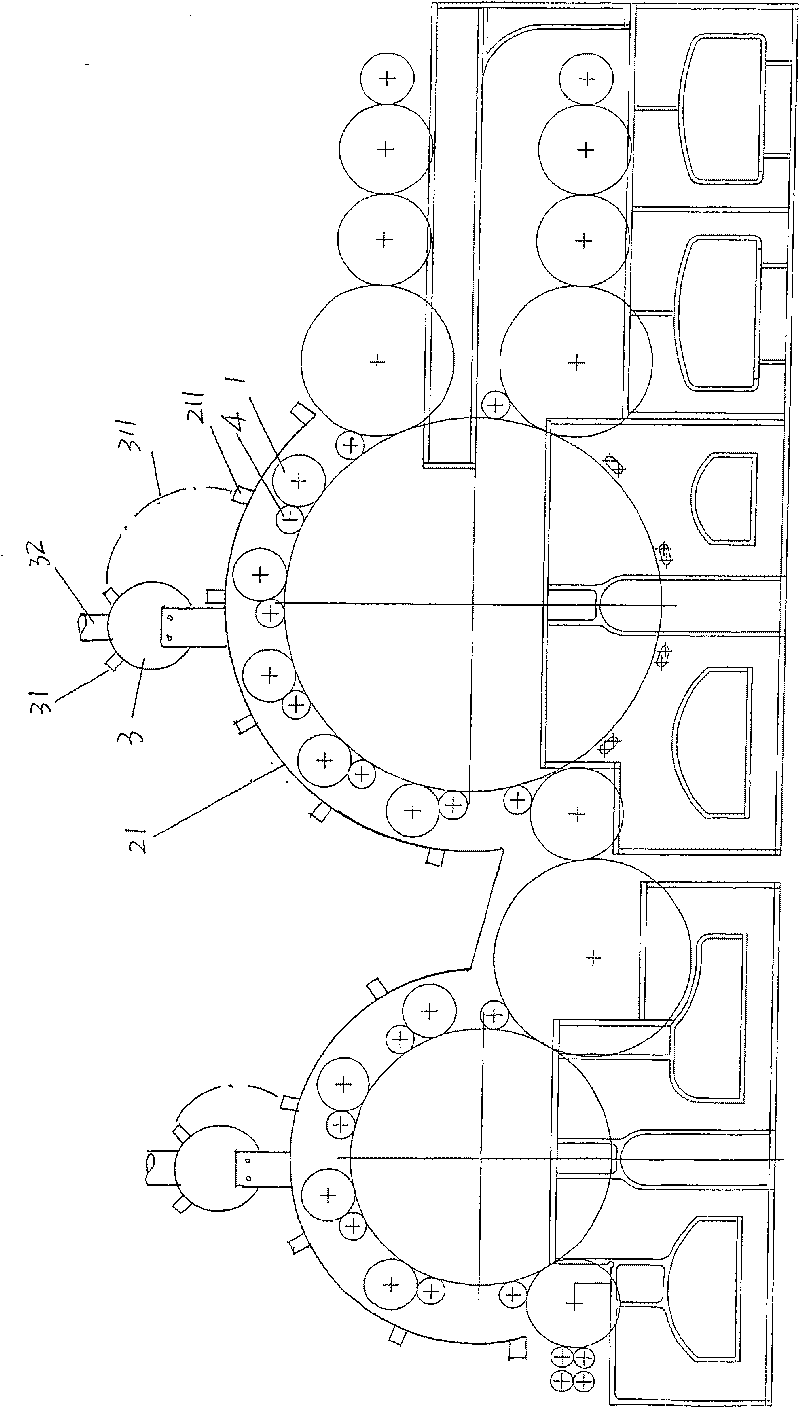

[0021] please see Figure 4 , it is provided that the air collecting pipe 3 of the edge suction device is directly arranged on the two ends of the roller cover 2 of the carding machine, and is fixed with the side plates 22 at both ends of the roller cover 2, and the suction nozzle 31 on the air collecting pipe 3 is directly probed. Into the carding cylinder 1 and above, in this case it is not necessary to be equipped with a connecting pipe 311 and a suction nozzle 211 as in Embodiment 1. All the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com