Tower crane rotation process state control method

A control method and technology of process status, applied in the directions of load hanging components, transportation and packaging, etc., can solve the problems of construction progress impact, adverse impact on the service life of tower cranes, tower crane safety accidents, etc., and achieve the effect of ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings:

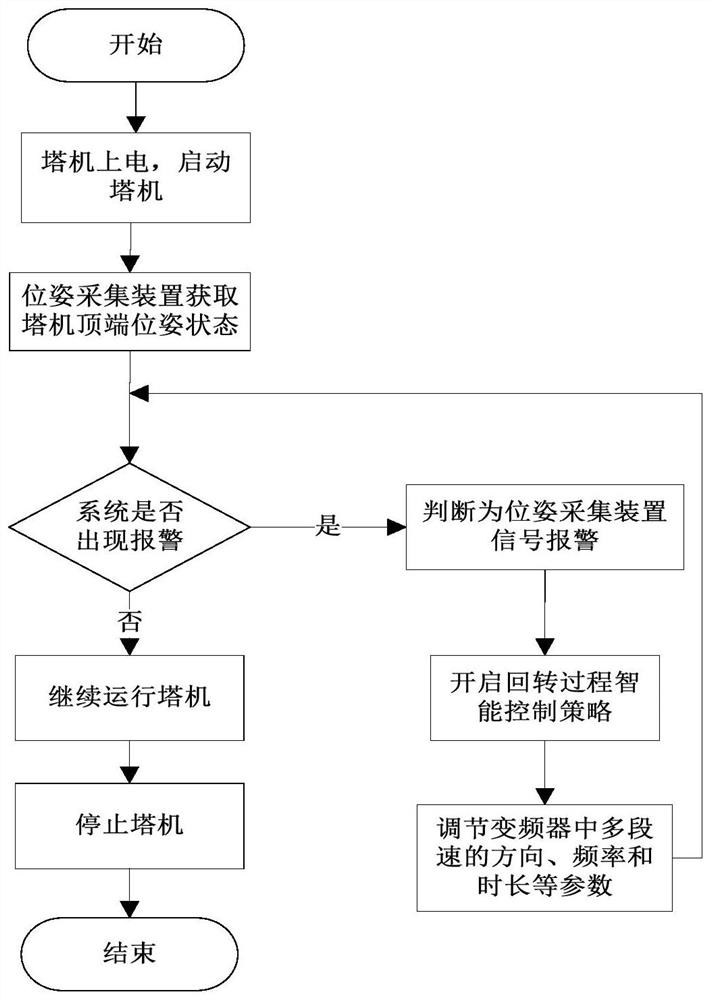

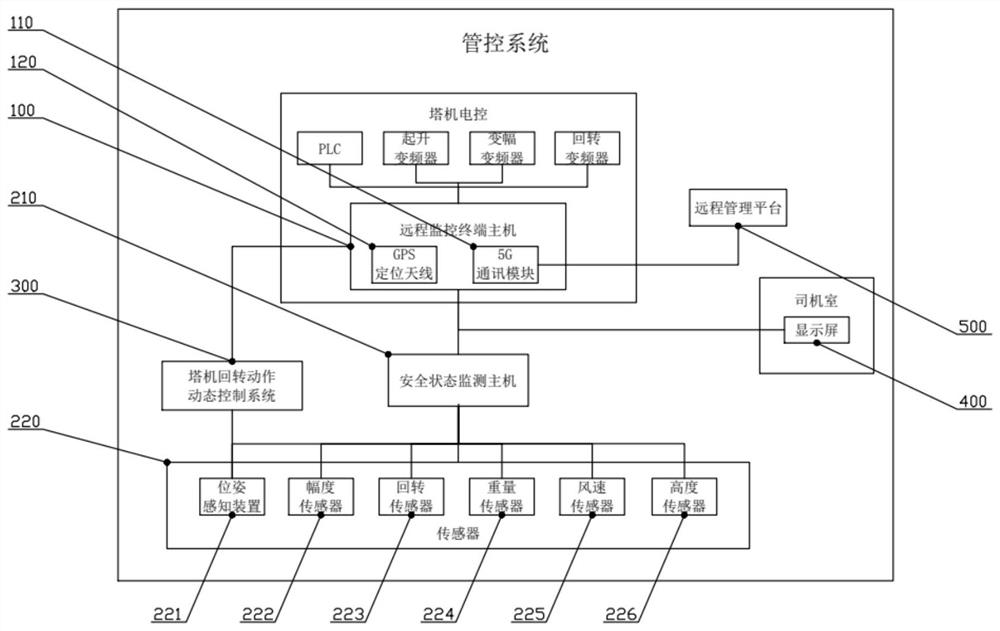

[0029] like figure 1 The state control method of the tower turning process according to the present invention is based on figure 2 The control system shown is implemented. The control system includes an electrical monitoring and a remote debug unit, a tower operation state monitoring unit, a tower rotary action dynamic control unit, and a display screen.

[0030] Specifically, the electrical monitoring and remote debug unit includes an electrical system monitoring terminal host 100, a remote management platform 500, a PLC controller, a booming frequency converter, a variable amplitude frequency converter, and a back-converter; the electrical system monitoring terminal host There is a 5G communication module 110 in the inner. The tower operanding state monitoring unit includes a security state monitoring host 210, a bit position perception device 221, an amplitude sensor 222,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com