Quick positioning locking mechanism

A positioning locking and fast technology, applied in the direction of bolts, etc., to achieve the effect of quick disassembly and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

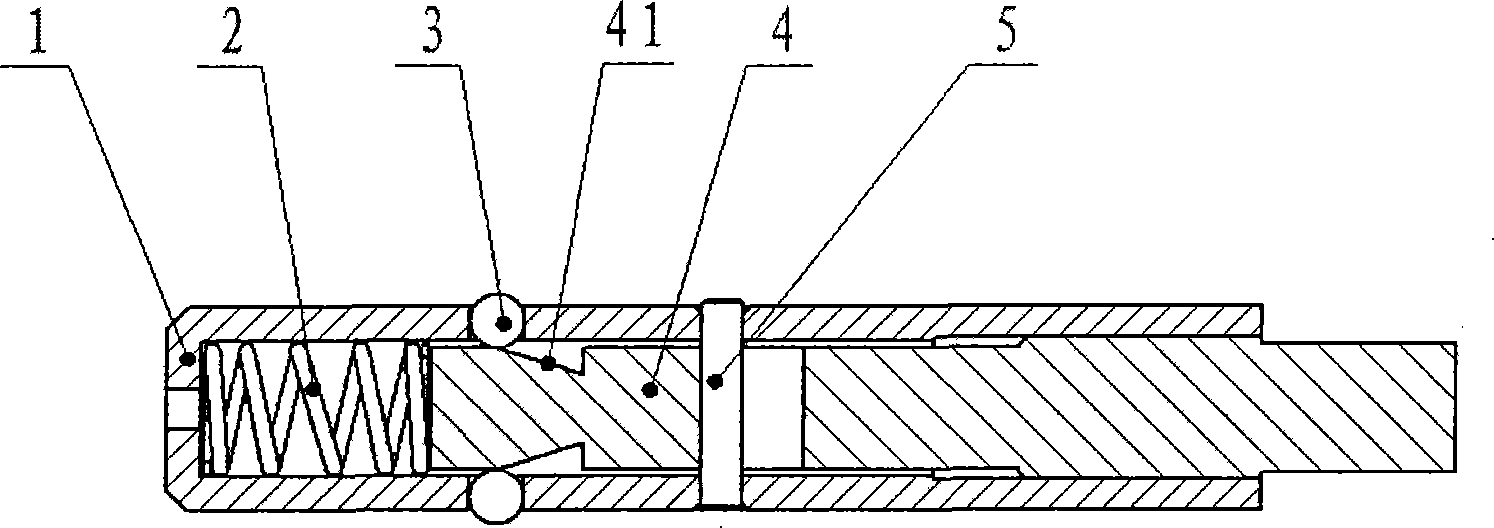

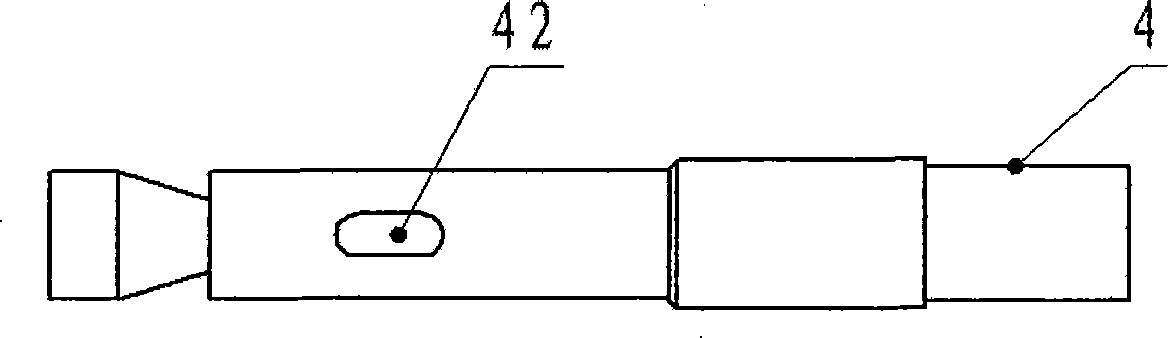

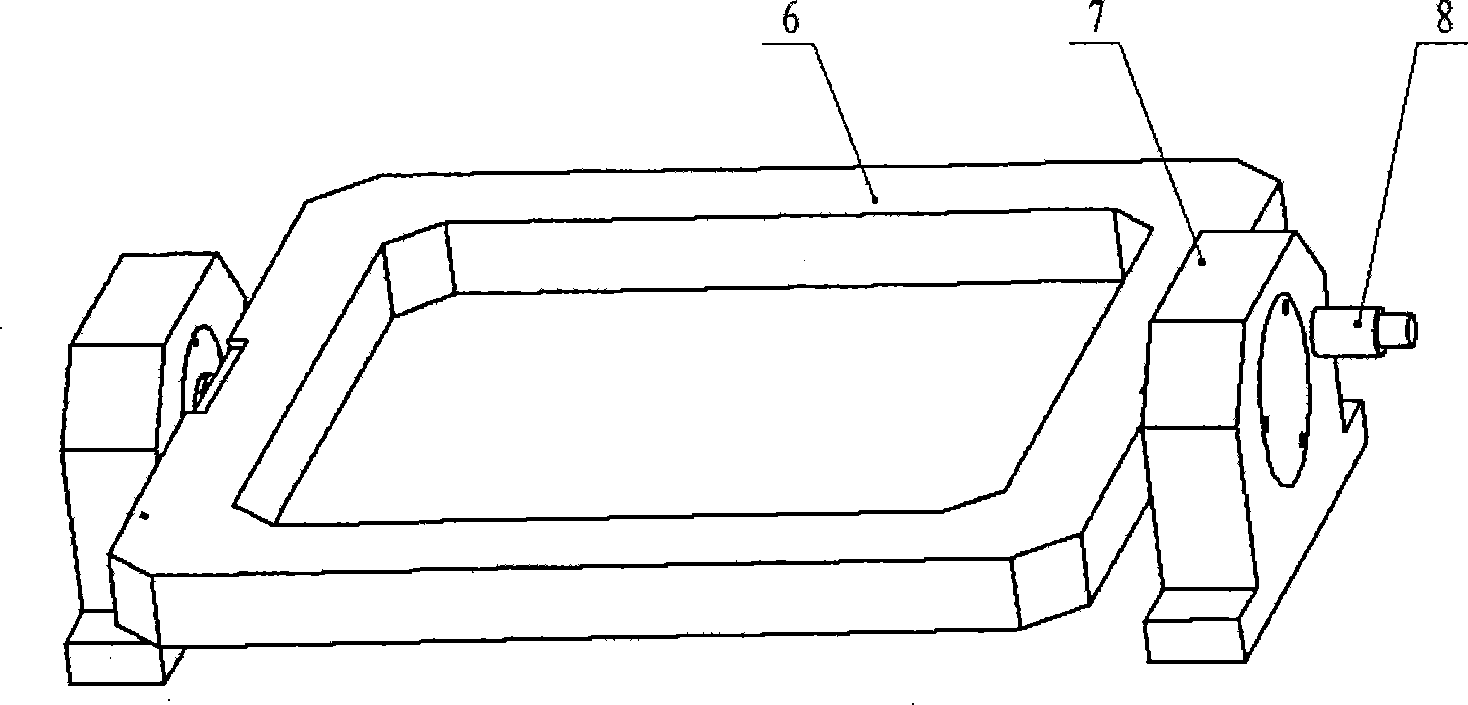

[0014] refer to figure 1 , 2 , a fast positioning locking mechanism, including a lock sleeve 1 with a bottom cover at one end, a pin shaft 4 that can slide axially in the inner cavity of the lock sleeve 1, and is arranged at the bottom end of the inner cavity of the lock sleeve 1 and the left end of the pin shaft 4 The compression spring 2 that part conflicts; On the right side of the end portion where the pin shaft 4 abuts against the compression spring 2, a section of conical surface 41 constricting to the right is provided, and on the pin shaft 4 on the right side of the conical surface 41, there is a hole that runs through it. The diameter of the axial guide groove 42, a limit guide post 5 that can slide axially along the pin shaft 4 is inserted in the axial guide slot 42, and the two ends of the guide post 5 are inserted in the lock sleeve 1 On the cavity wall; on the cavity wall of the lock sleeve 1, there are two radially symmetrical through holes corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com