Threshing apparatus

A technology of threshing and sorting device, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of unpredictable sorting performance and no screening function, and achieve accurate and good separation and sorting, The effect of improved sorting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the embodiment of this invention is concretely demonstrated based on drawing.

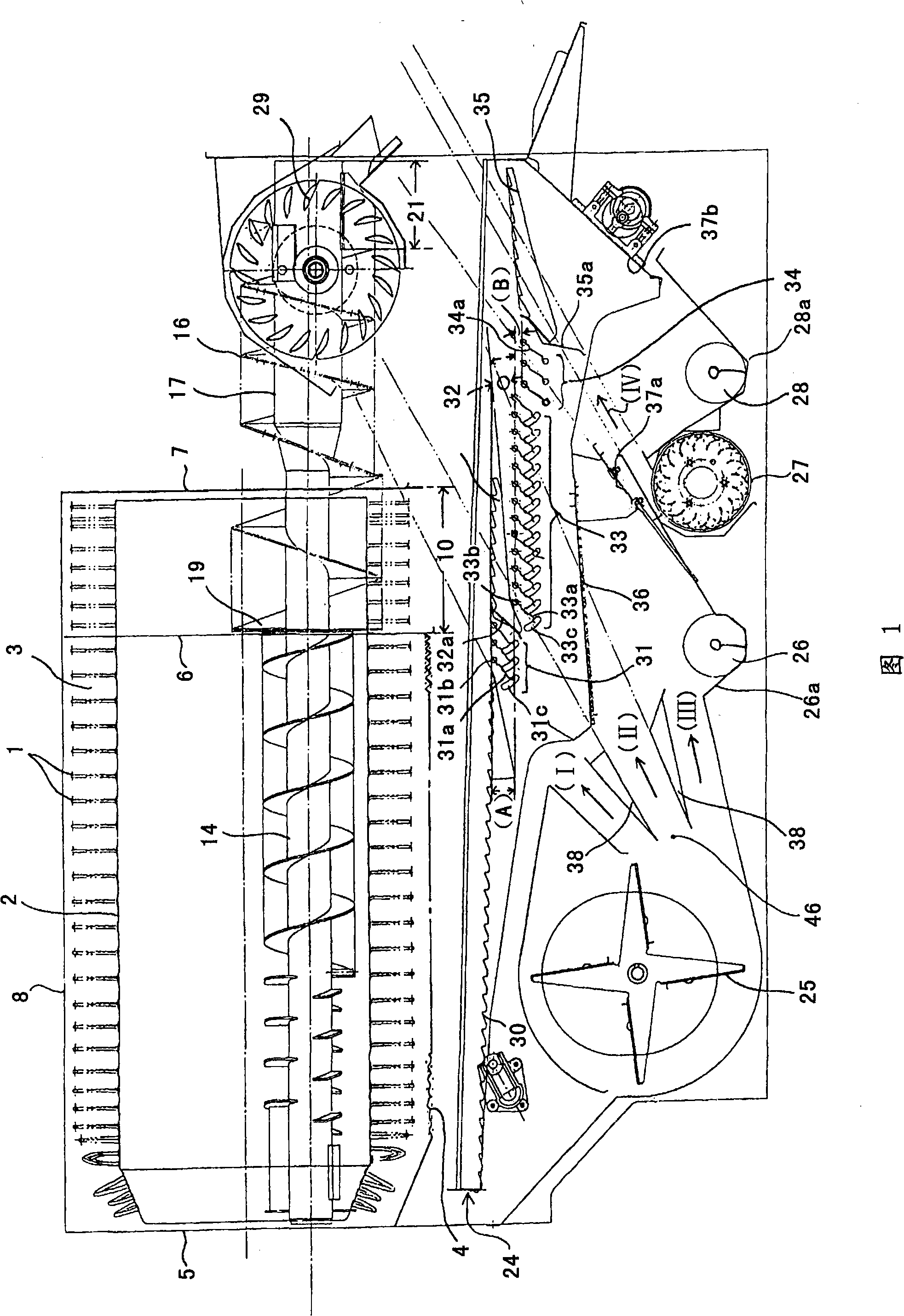

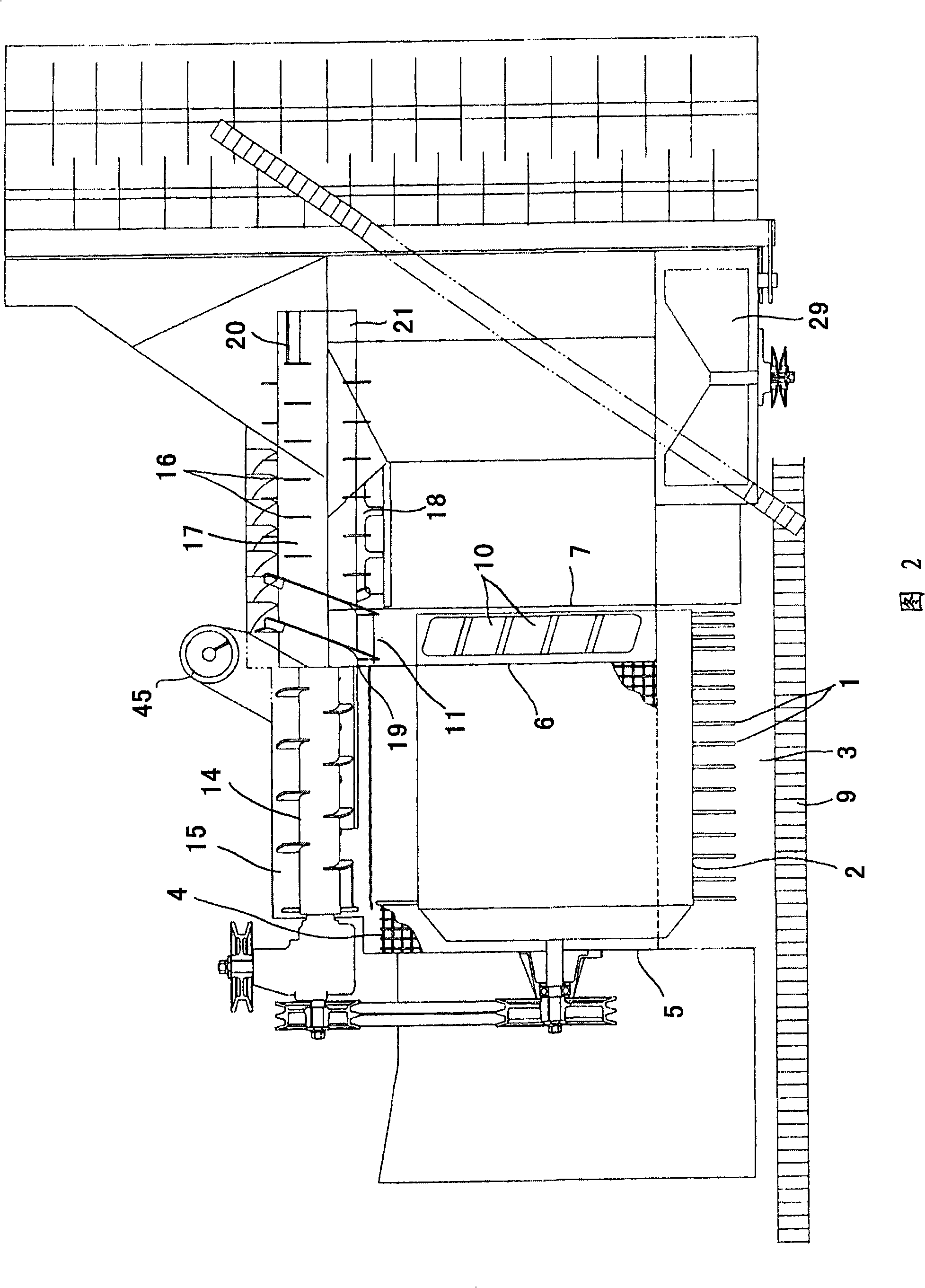

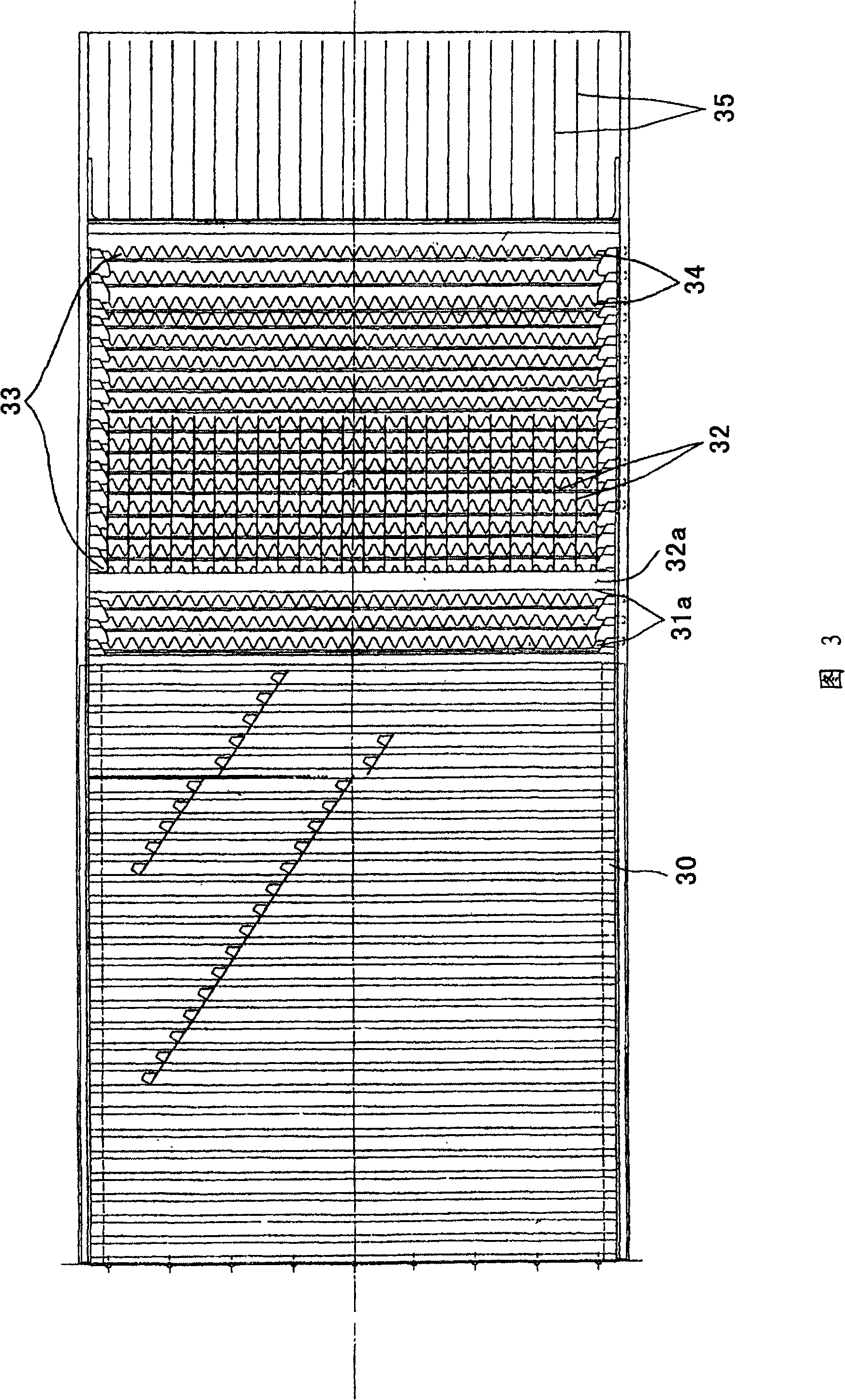

[0033] Fig. 1 and Fig. 2 show a threshing device mounted on a combine harvester.

[0034] The receiving net 4 is spread and arranged along the lower half circumference of the threshing chamber 3 in which the threshing drum 2 with the threshing gear 1 is rotatably installed. The receiving net 4 is arranged between the front side plate 5 and the middle side plate 6 of the threshing chamber. 8 is the threshing cylinder cover that covers the upper part of the threshing chamber 3, and is made into a structure that can swing open and close around the axis parallel to the rotation axis of the threshing cylinder 2.

[0035] On the side of the threshing port of the threshing chamber 3, a threshing feed chain 9 for clamping and transporting straw is provided. The terminal side of the threshing chamber 3 is provided with a first dust discharge port 10 that makes the dust discharge treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com