Method for operating inking device of printer

A technology of printing ink and ink infusion, which is applied to the general parts of printing machinery, printing machines, printing, etc., and can solve problems such as the difficulty of accurately measuring the amount of ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

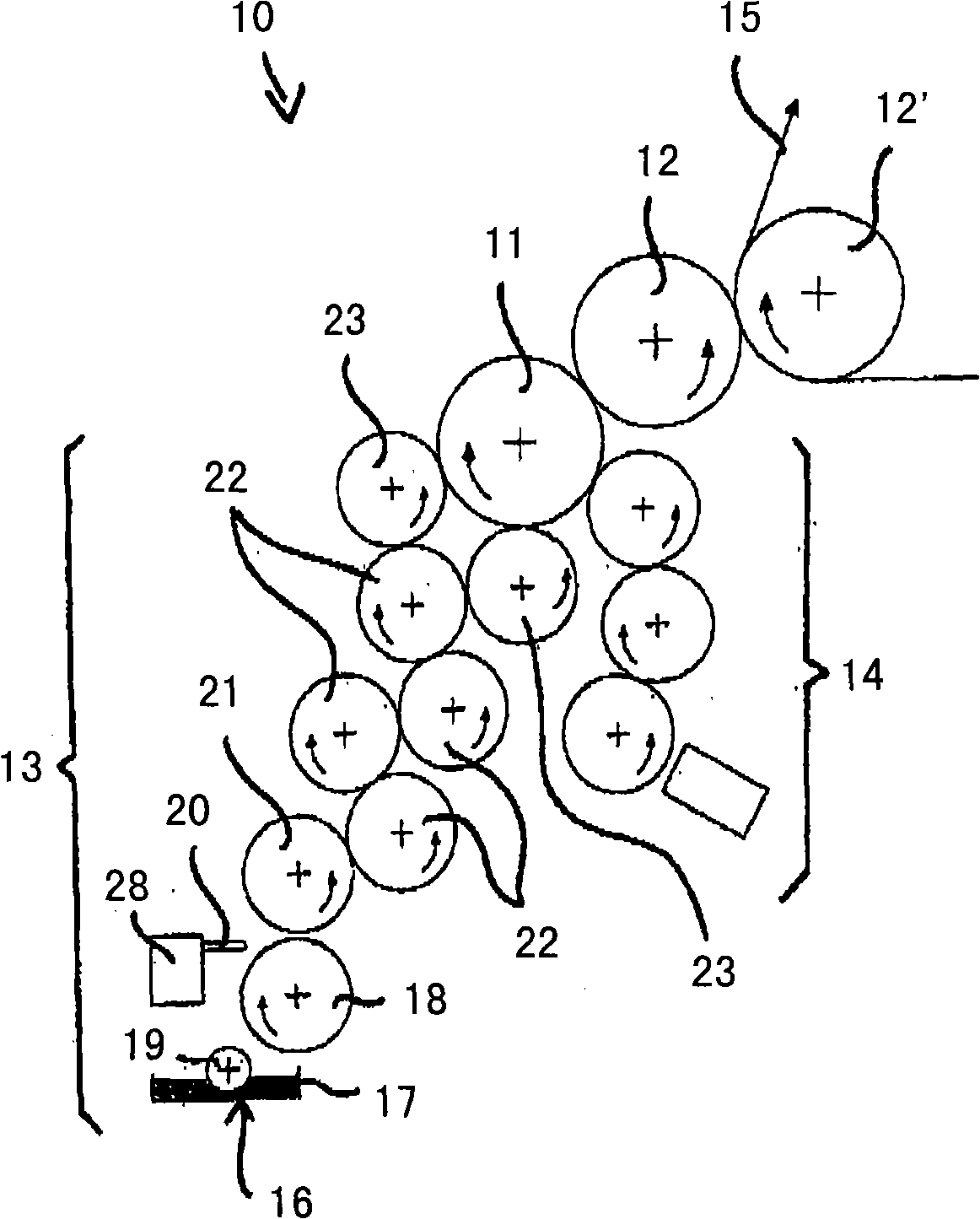

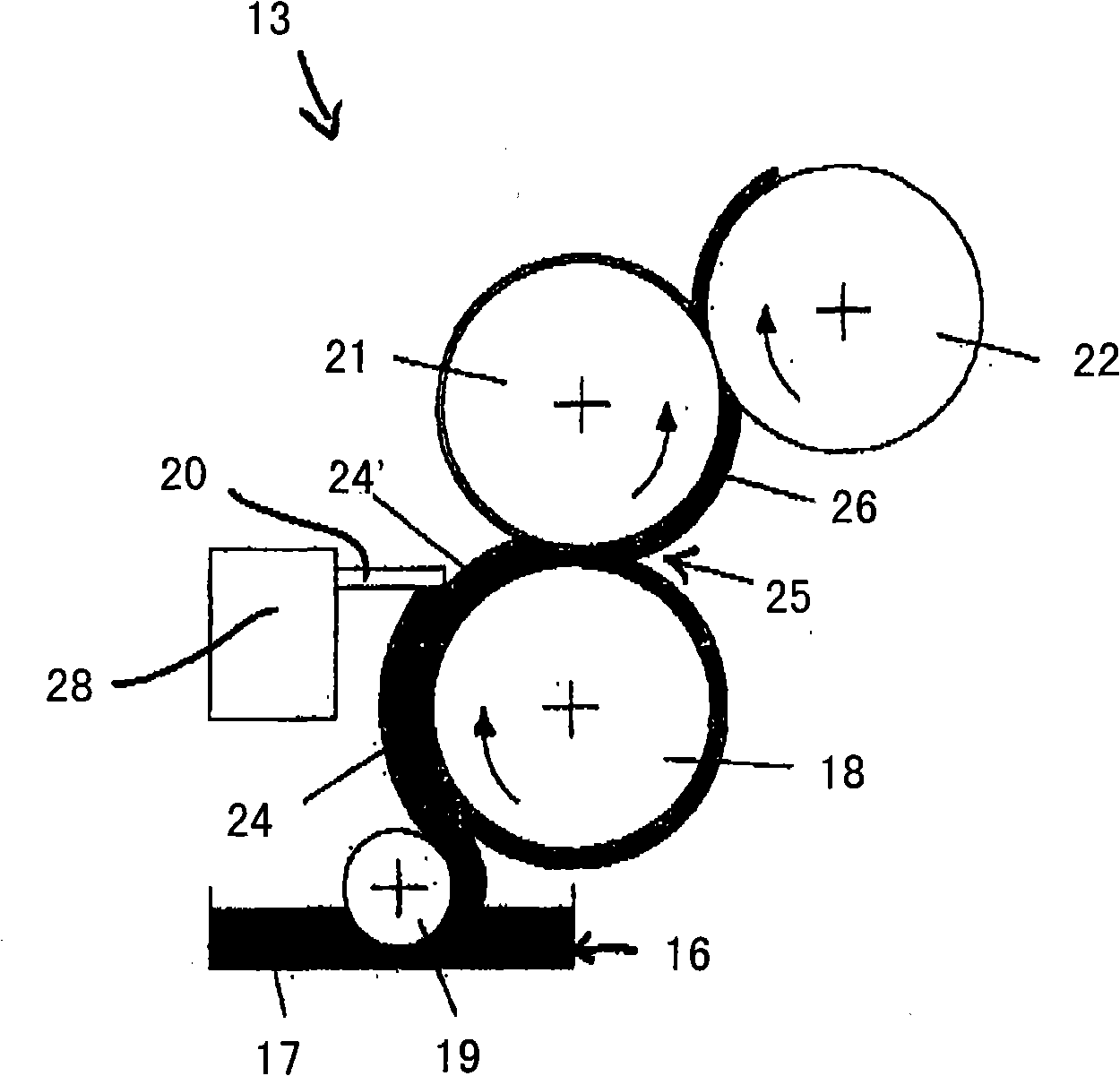

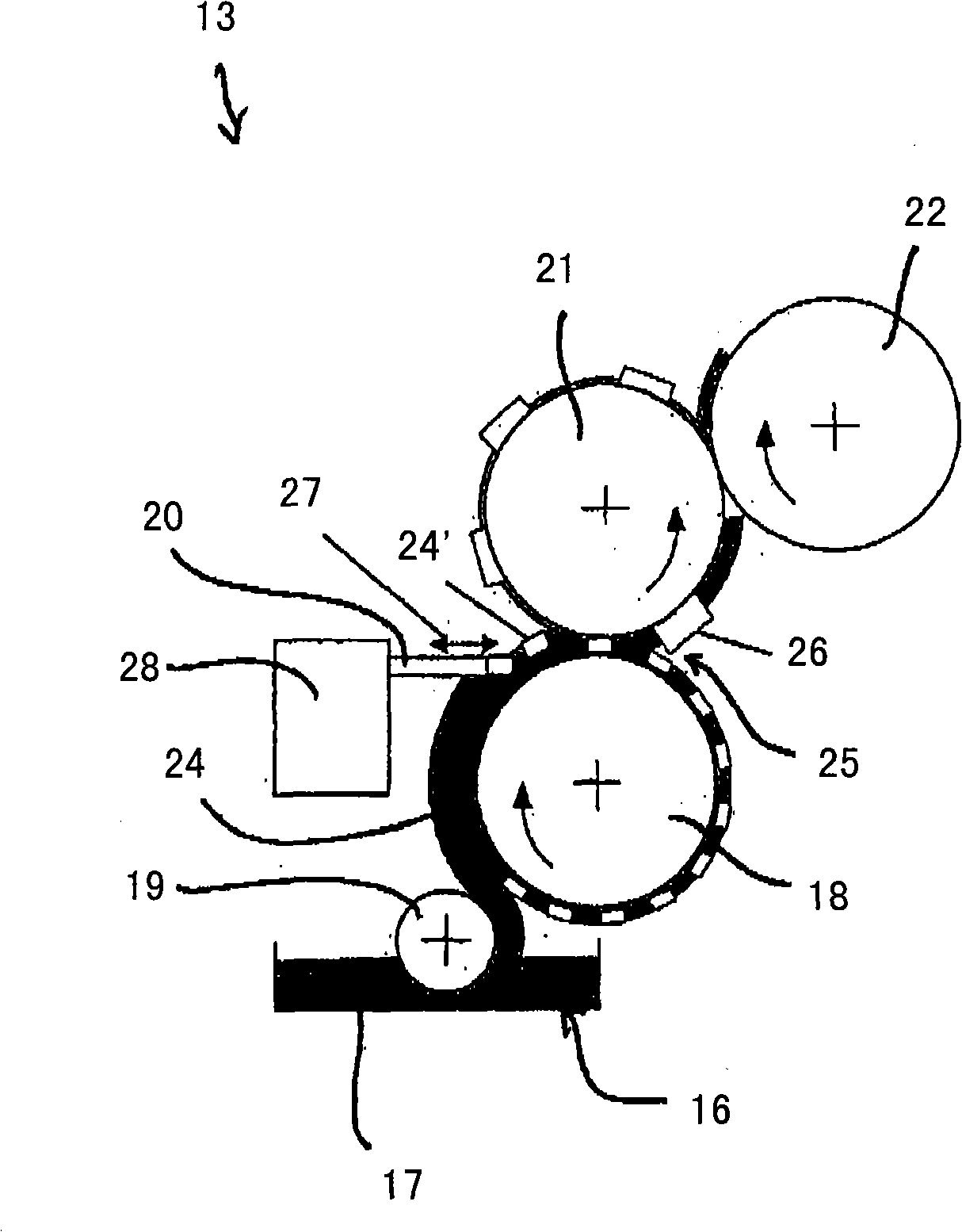

[0032] With the help of Figures 1 to 3 The present invention will be described in detail.

[0033] figure 1 A schematic diagram of a printing unit 10 of a rotary printing press is shown, wherein the printing unit 10 includes a printing plate cylinder 11 , a transfer cylinder 12 , an inking unit 13 and a dampening unit 14 . The printing ink is applied to at least one printing plate positioned on the plate cylinder 11 by means of the inking unit 13 , while the dampening agent can be applied to the or each printing plate by means of the dampening unit 14 . The printing ink coated on the plate cylinder 11 is transferred to the printing material 15 by means of the transfer cylinder 12, wherein, according to figure 1 On the transfer cylinder 12 of the printing unit 10 the transfer cylinder 12 ′ of the other printing unit is rolled.

[0034] The inking unit 13 of the printing unit 10 has an ink fountain 16 in which printing ink 17 is prepared. The inking roller 18 draws printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com