Oil-submersible electric membrane pump

A diaphragm pump and electric technology, applied in pumps, machines/engines, pumps with flexible working elements, etc., can solve problems such as increased energy consumption, reduced oil discharge, and reduced pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

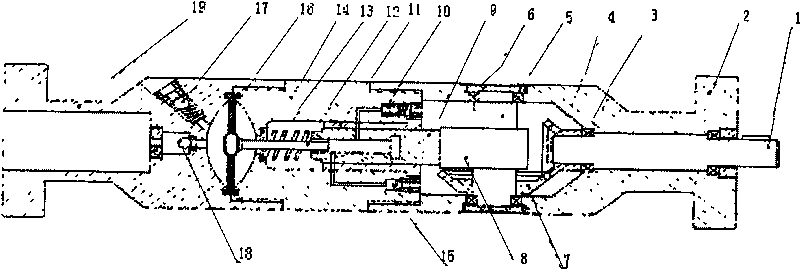

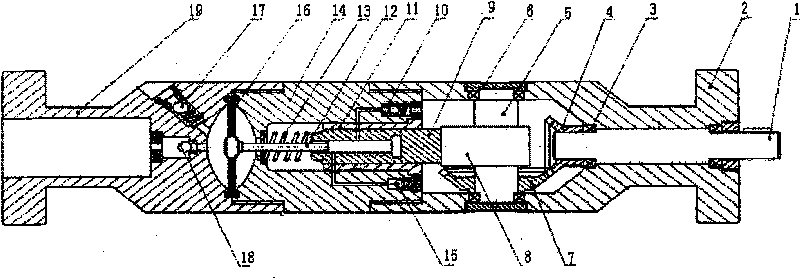

[0008] Embodiment 1: Referring to the accompanying drawings, the pump body is composed of three parts, the upper pump body 19, the middle pump body 14 and the lower pump body 2, which are connected by threads to form a whole. The lower part of the lower pump body 2 is axially penetrated with a transmission shaft 1, the exposed part of the transmission shaft 1 is connected with the motor, the upper part of the transmission shaft 1 is connected with an axial bevel gear 4, and the joint between the transmission shaft 1 and the lower pump body 2 is provided There are sealed bearings3. A camshaft 5 is radially fixed in the upper chamber of the lower pump body 2, and a cam 8 is arranged in the middle of the camshaft 5. Bearings and bearing caps 6 are arranged at both ends of the camshaft 5 and the junction of the lower pump body 2. On the camshaft 5 A radial bevel gear 7 engaged with the axial bevel gear 4 is fixed to realize the radial rotation of the camshaft 5 . The cavity is fi...

Embodiment 2

[0011] Embodiment 2: On the basis of the above embodiments, the plunger bushing 11 is omitted, which has the same effect, but the smooth and sealing fit between the plunger 9 and the inner wall of the intermediate pump body 14 must be maintained. The lower pump body 2 and the upper pump body 19 have a flange at the end, which is convenient for the lower end of the pump to be connected to the motor, and the upper part to be connected to the pipe string. The pump body is connected by threads, and the seal is reliable. For smaller wellbores.

[0012] Its working principle is: the transmission shaft is connected with the submersible motor, and the motor drives the bevel gear on the transmission shaft to rotate, and transmits the power to the radial bevel gear, which rotates together with the camshaft and the cam, pushing the plunger to reciprocate up and down, through The oil drain valve and the oil inlet valve suck and discharge the hydraulic oil in the lower pump body, and push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com