Full-automatic static mixer

A static mixer, fully automatic technology, applied in the direction of various fluid ratio control, etc., can solve the problems of low degree of automatic control of the mixer, low production efficiency, etc., to save costs, avoid production waste, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

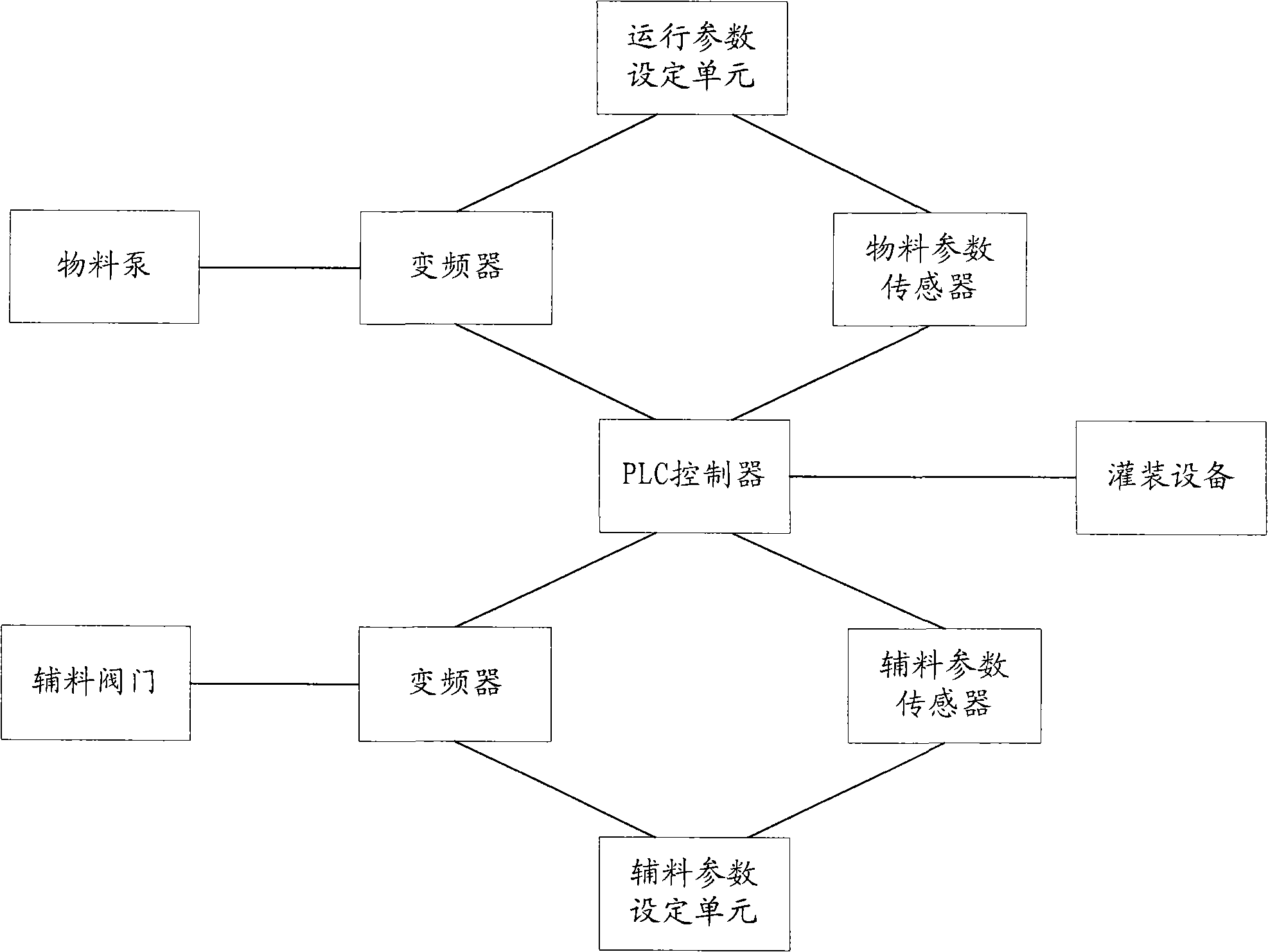

[0024] see figure 1 , figure 1 It is a structural diagram of an embodiment. In this embodiment, the fully automatic static mixer includes a feeder and a homogenizer, wherein the feeder includes:

[0025] The operating parameter setting unit is used to set the pressure and flow sensing values of the material parameter sensor or set the frequency of the frequency converter;

[0026] Frequency converter, used for frequency conversion to control the driving motor of the material pump;

[0027] The material parameter sensor is used to sense the material pressure and flow through the material pump;

[0028] Homogenizers include:

[0029] The auxiliary material parameter setting unit is used to set the pressure and flow sensing value of the auxiliary material parameter sensor or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com