Gas odorizing control device and gas odorizing system

A control device and gas technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of poor odorization effect, odorant liquid difficult to natural gas, etc., to achieve energy saving and precise control of odorization Quantity, real-time correction of the effect of filling concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

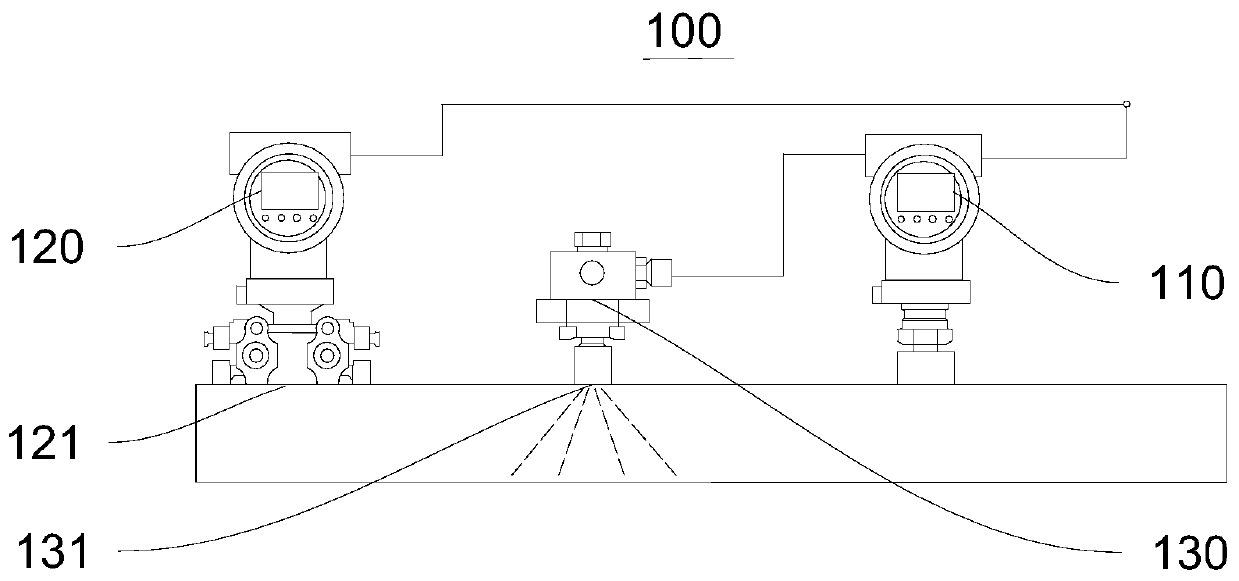

[0032] Please refer to figure 1 This embodiment provides a gas odorization control device 100 , including a control unit 110 , a first detection unit 120 , and an actuator 130 , and the control unit 110 is connected to the first detection unit 120 and the actuator 130 . In this embodiment, the gas pipeline has a first measurement position 121 , and the gas flows from the first measurement position 121 to a preset odorant input position 131 . The first detection unit 120 is located at the first measurement position 121 , and the actuator 130 is located at the odorant input position 131 .

[0033] The first detection unit 120 is used for measuring a first measurement parameter at a first measurement position 121 . There are multiple options for the first measurement parameter, and specific settings can be made according to the transportation requirements in the gas. For example, the first measurement parameter can include the pressure, temperature, flow rate, etc. of the gas in...

Embodiment 2

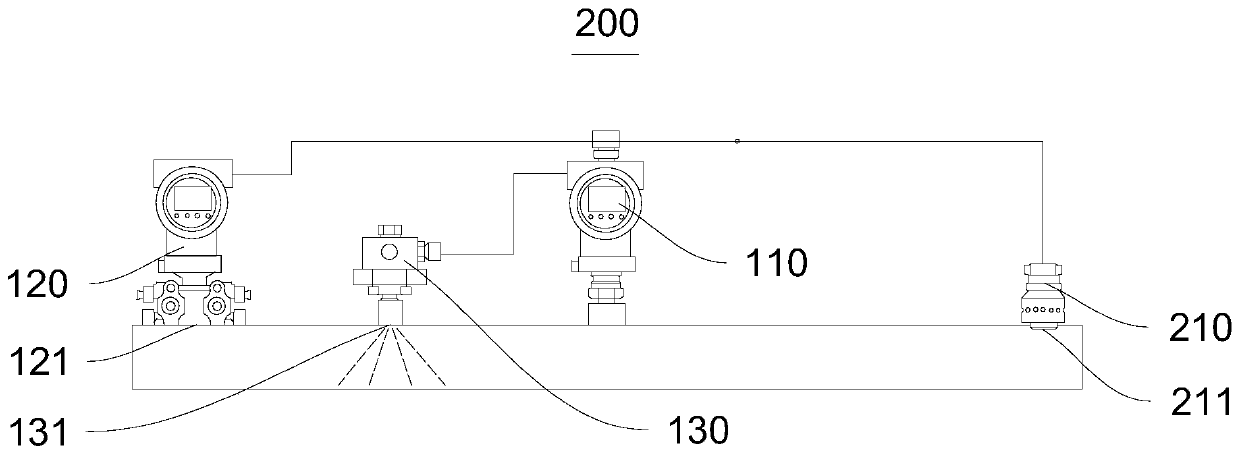

[0038] Please refer to figure 2 , the present embodiment provides a gas odorization control device 200, including a control unit 110, a first detection unit 120, a second detection unit 210, an actuator 130, the control unit 110 and the first detection unit 120, the second detection unit 210 , The actuator 130 is connected.

[0039] The difference from the gas odorizing control device 100 mainly lies in:

[0040] The gas pipeline has a second measurement position 211 , and the flow of gas is as follows: the gas flows from the first measurement position 121 to the second measurement position 211 through the preset odorant input position 131 . The second detection unit 210 is located at the second measurement position 211 . The second detection unit 210 is used for measuring the second measurement parameter at the second measurement position 211 . There are multiple options for the second measurement parameter, and specific settings can be made according to the transportatio...

Embodiment 3

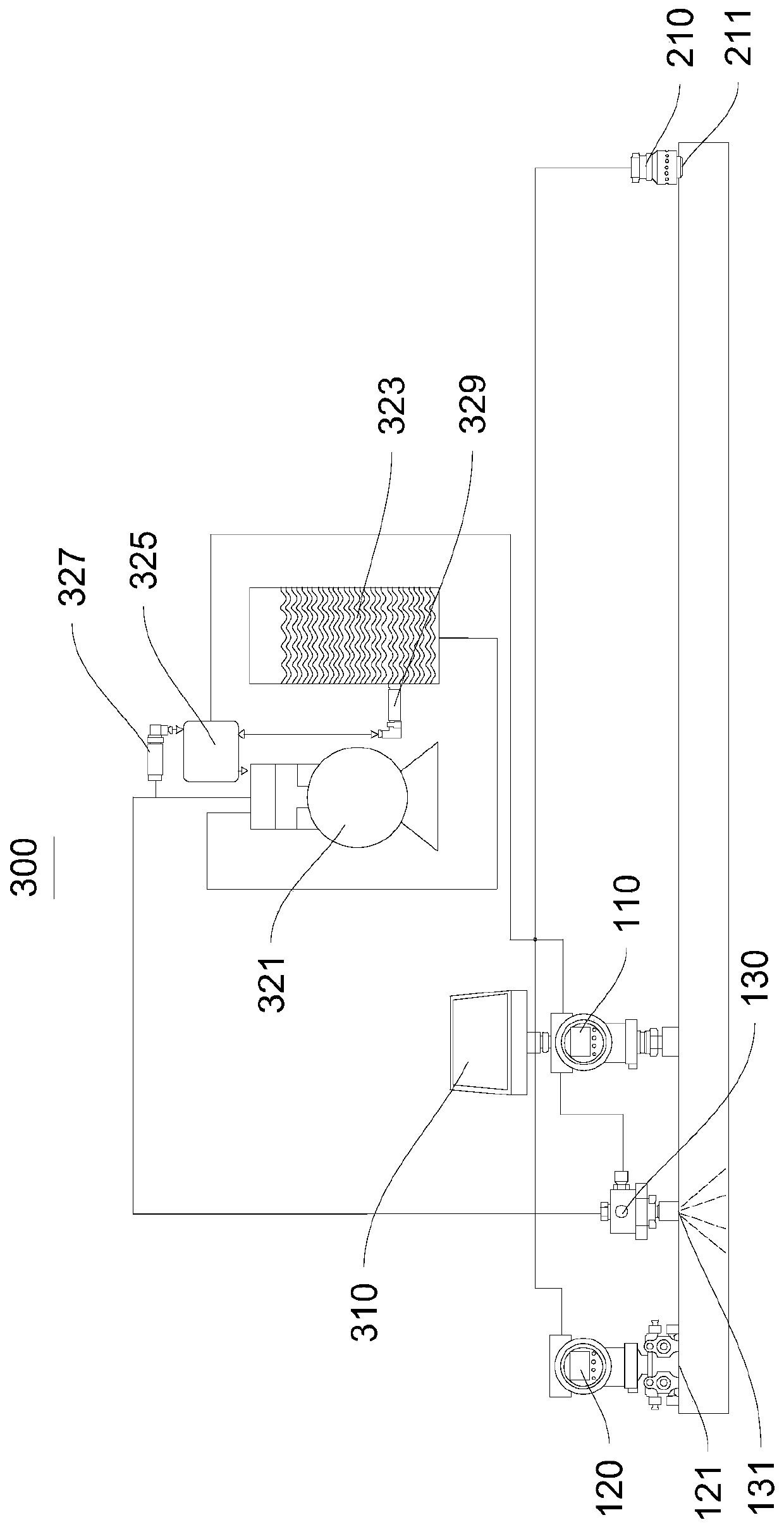

[0044] Please refer to image 3 This embodiment provides a gas odorizing system 300, including a power unit 310, a conveying device 320, and a gas odorizing control device 200, and the power unit 310 and the conveying device 320 are respectively connected to the gas odorizing control device 200.

[0045] In this embodiment, the power device 310 is a solar panel assembly, which provides power to the gas odorization control device 200. In other embodiments of the present invention, the power device 310 can also be other power supply equipment, such as a generator.

[0046] The conveying device 320 includes a pump 321, an odorant storage tank 323, a pressure stabilizer 325, and a pressure gauge 327. The pump 321 is connected to the odorant storage tank 323, and the pressure stabilizer 325 is connected to the pump 321 and the odorant storage tank 323 respectively. .

[0047] The pressure gauge 327 measures the pressure value output from the pump 321 and feeds the pressure value b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com