Apparatus and method for pasting adhesive label

An adhesive label and sticking device technology, applied in the directions of labeling, labeling, packaging, etc., can solve the problems of increased cost and non-economical efficiency, and achieve the effect of simplifying the structure and realizing economical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

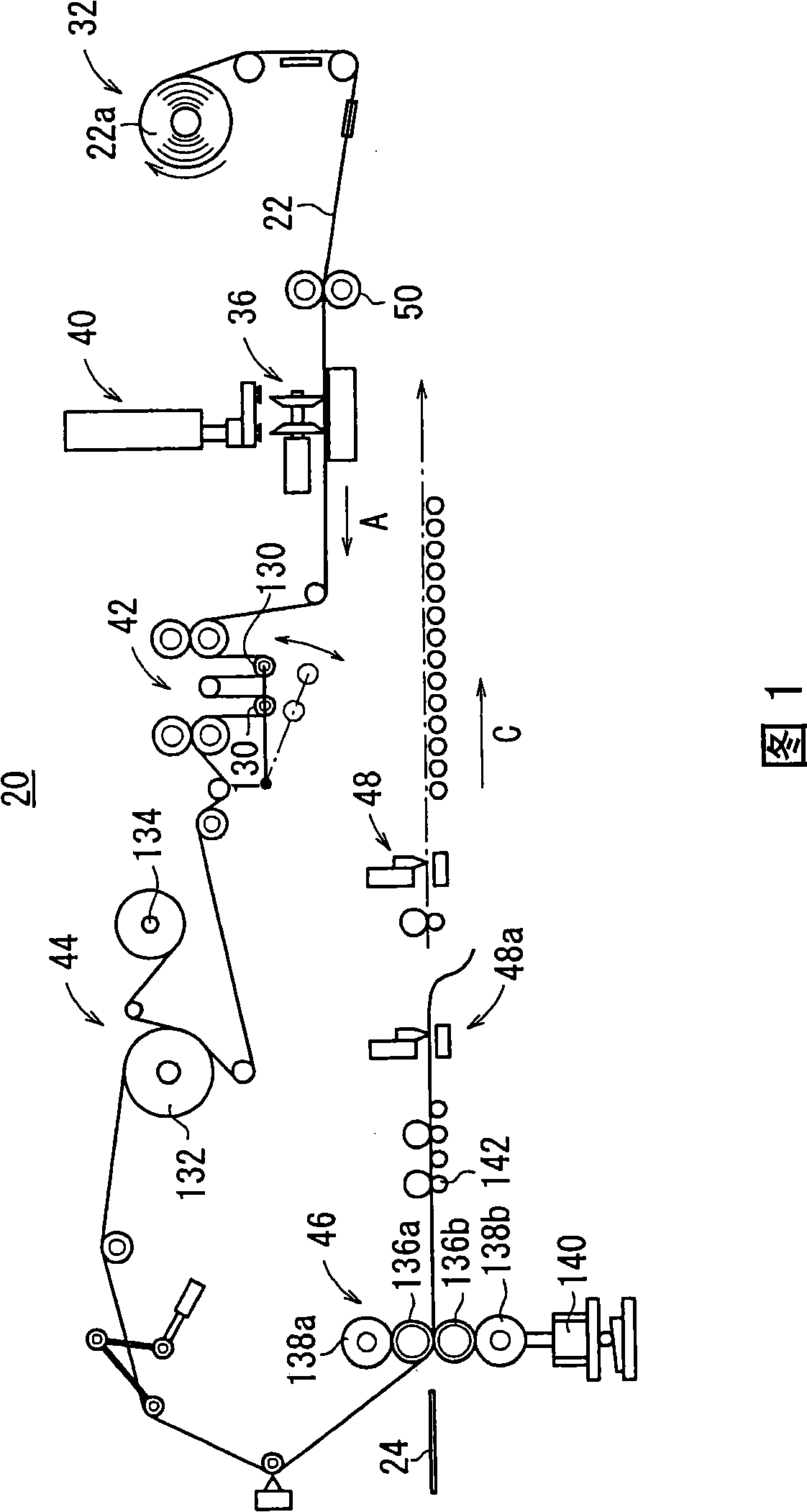

[0035] Fig. 1 is a schematic configuration diagram showing a manufacturing device to which an adhesive label sticking device and a method thereof according to an embodiment of the present invention are applied. The manufacturing apparatus 20 performs thermal transfer of a photosensitive resin layer 28 (described later) of a long photosensitive sheet 22 onto a glass substrate 24 in a manufacturing process of a color filter for liquid crystal or PDP.

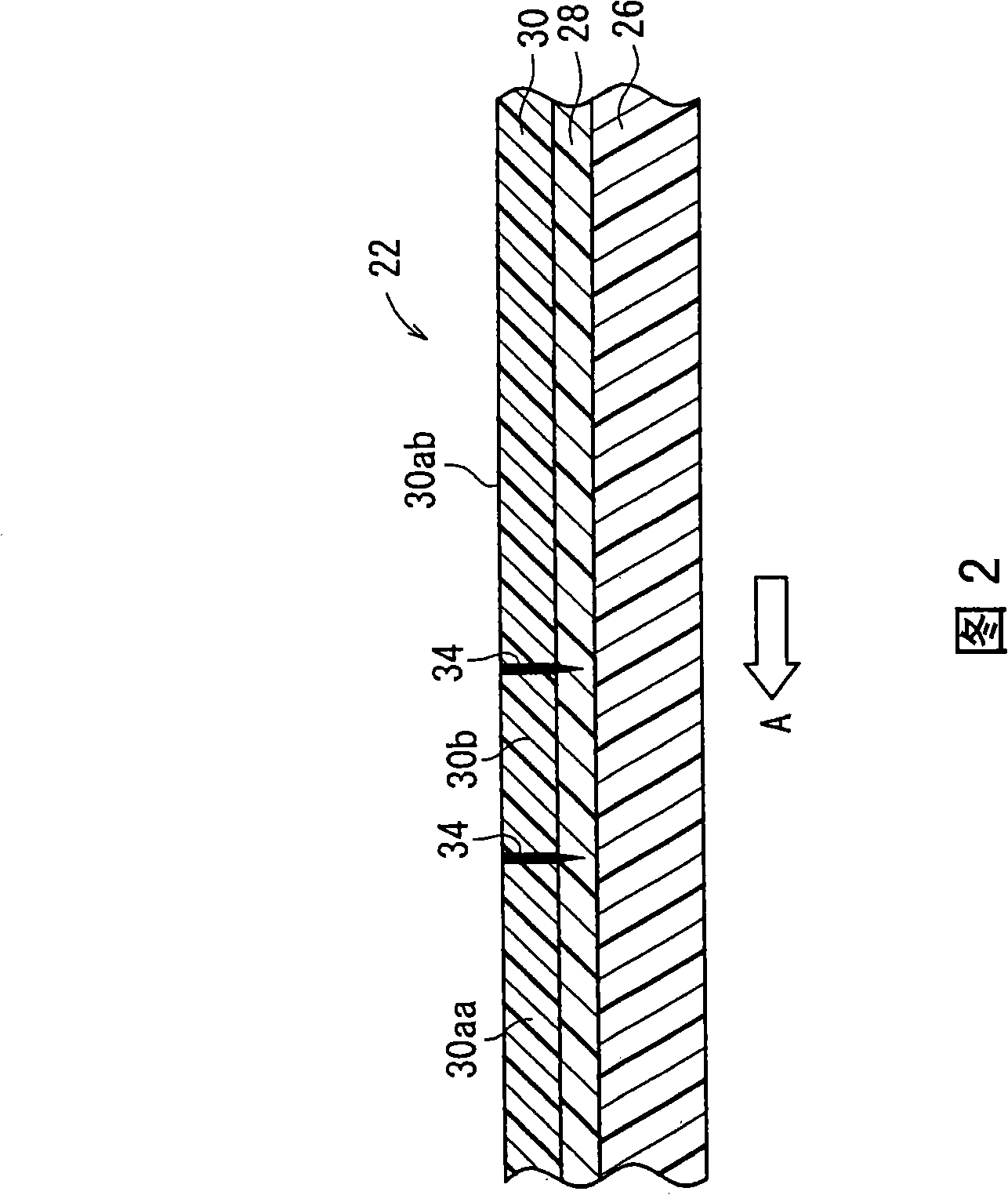

[0036] FIG. 2 is a cross-sectional view showing a long photosensitive sheet 22 used in the manufacturing apparatus 20. As shown in FIG. The photosensitive sheet 22 is formed by laminating a flexible base film (support) 26 , a photosensitive resin layer (photosensitive material layer) 28 , and a protective film 30 .

[0037] As shown in FIG. 1 , the manufacturing apparatus 20 is provided with a photosensitive sheet roll 22a that accommodates a photosensitive sheet 22 wound into a roll shape, and the photosensitive sheet is fed out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com