Joint box sealing device adopting screw cap rotating impacted sealing ring automatic enclasping optical fibre cable

A technology of compression sealing and sealing device, which is applied in the direction of cable entry sealing device, cable installation, optical waveguide coupling, etc. It can solve the problems of shortened service life of the joint box, inconvenient construction and expansion, and poor sealing performance, etc., to achieve Long-term reliable sealing, ensuring long-term safe operation, and ensuring the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

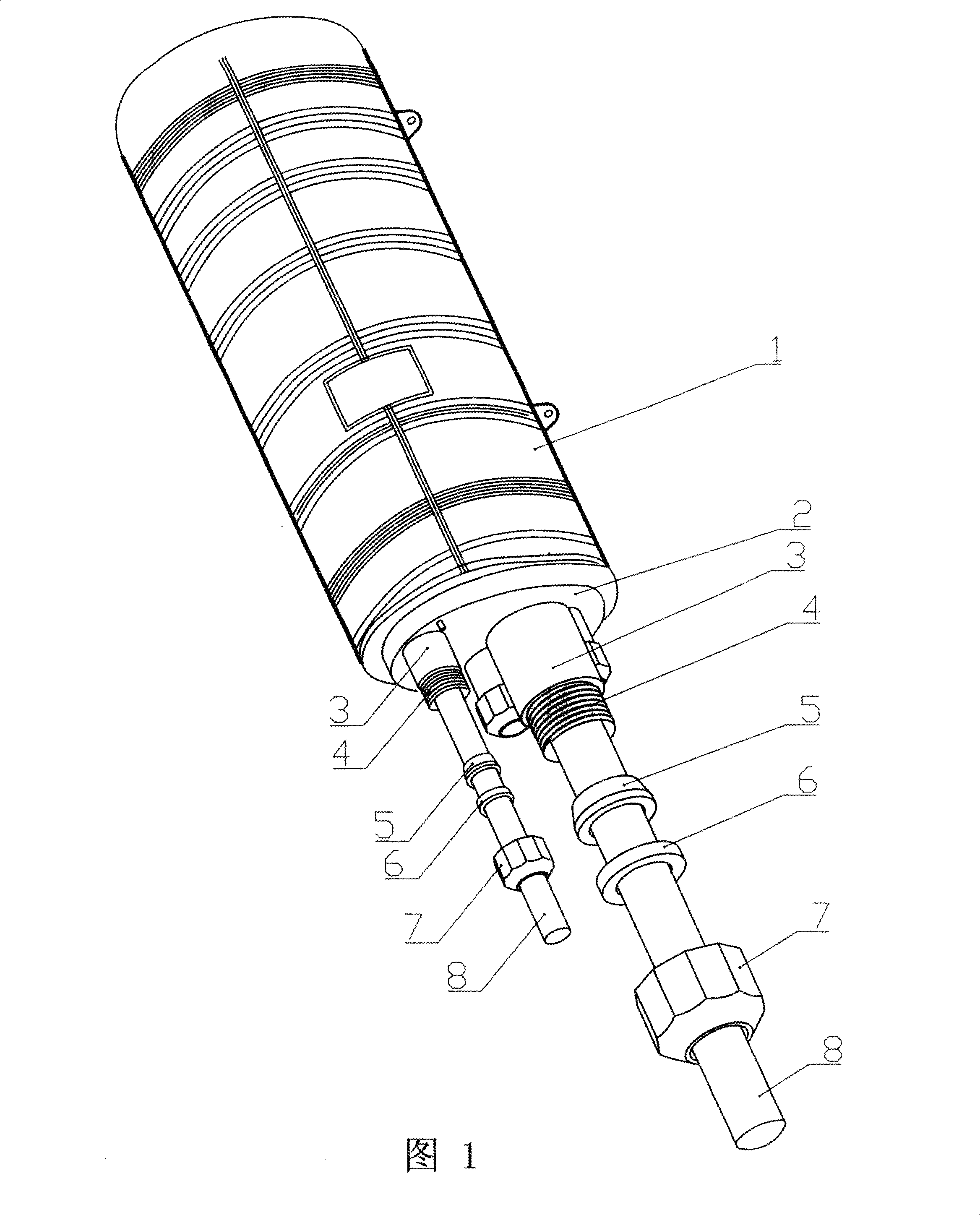

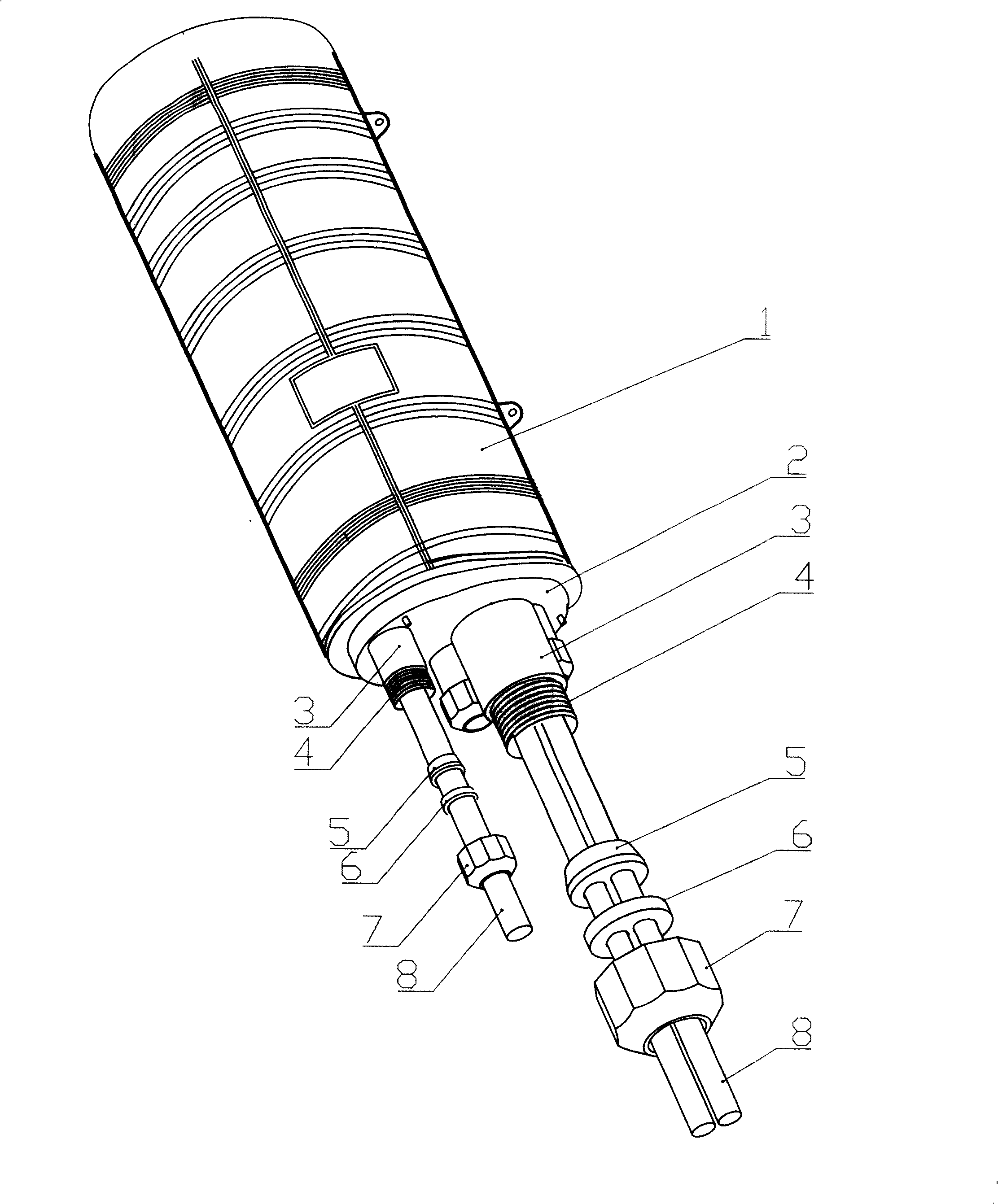

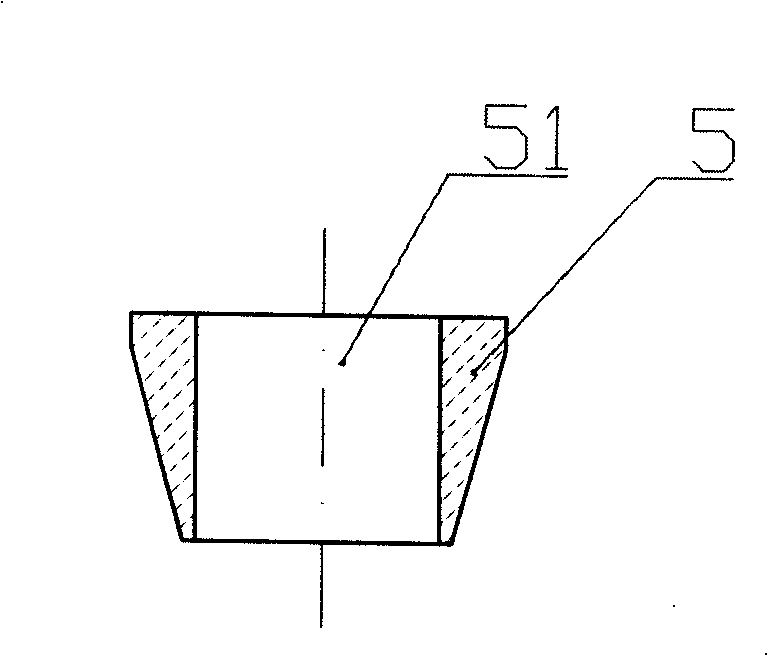

[0054] See Figure 1~ Figure 37 , the basic structure of the present invention comprises optical cable inlet and outlet pipe 3, nut 7, plastic washer 6 and elastomer seal ring 5, and described optical cable inlet and outlet pipe 3 is on the box bottom 2 of optical cable connector box body 1, and the optical cable inlet and outlet pipe 3 An external thread 4 is provided on the outside, and the nut 7 is provided with an internal thread matching the external thread 4. When assembling, the optical cable 8 is passed through the cable hole of the nut 7, the plastic gasket 6 and the cable hole of the elastomer sealing ring 5 in sequence. , and then tighten the nut 7 on the external thread 4 of the cable inlet and outlet tube 3, so that the inlet and outlet cables can be tightened and sealed, and the installation and operation are convenient. The positions of the optical cable hole of the plastic gasket 6 and the optical cable hole of the elastomer sealing ring 5 correspond to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com