Vertical rigidity changeable shock insulation support saddle

A technology of seismic isolation bearing and variable stiffness, which is applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of difficult application and promotion, poor isolation effect, large deformation, etc., and achieves large vertical deformation capacity. and the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

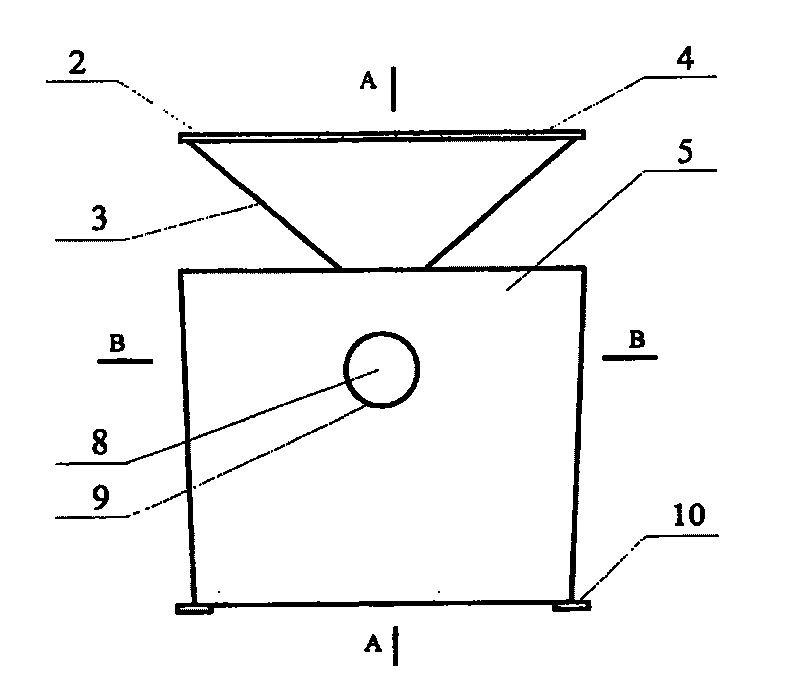

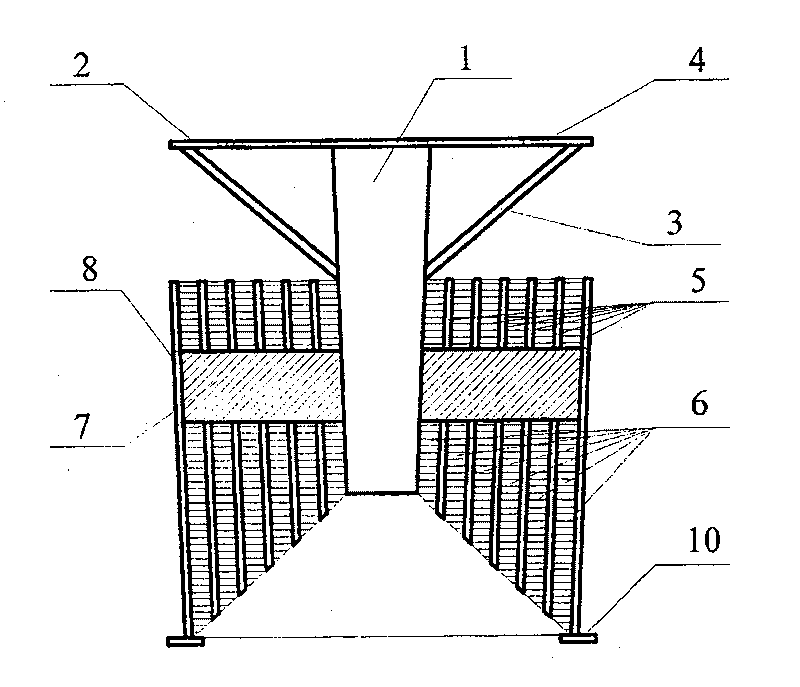

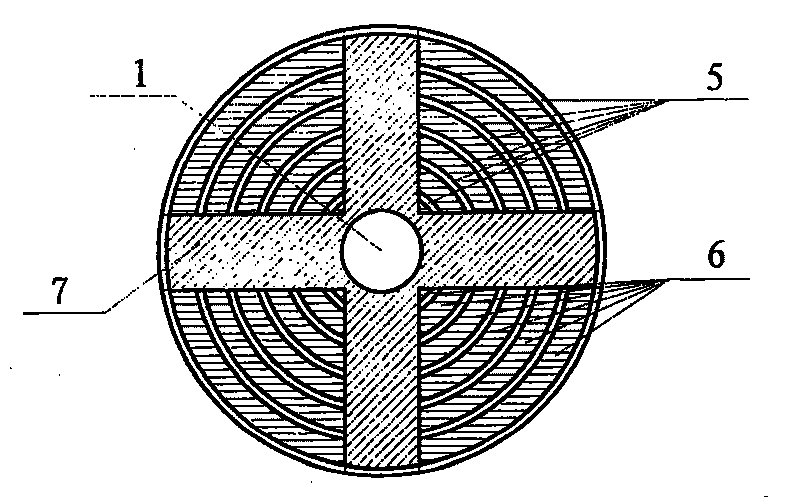

[0035] Such as figure 2 As shown, this support includes a variable stiffness guide device, a lead core 7, a plurality of steel cylinders 5 and rubber 6 (the rubber 6 here is a rubber ring with a certain thickness), and the steel cylinder 5 and rubber ring 6 are the upper ports. A conical shape with an area greater than that of the lower port. The structure of the variable stiffness guiding device is as follows: Figure 4 As shown, it includes three parts: the shaft 1, the top plate 2 and the variable stiffness curved panel 3, and the curvature of the variable stiffness curved panel 3 is zero. One end of the shaft 1 with a larger diameter is fixedly connected to the top plate 2 , one end of the tapered variable stiffness curved plate 3 is fixedly connected to the top plate 2 , and the other end is fixedly connected to the side of the shaft 1 . The shaft 1 is surrounded by a rubber ring 6 with a certain thickness. The rubber ring 6 is covered with a steel cylinder 5. The mult...

Embodiment 2

[0043] Figure 6 It is another embodiment of the present invention, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the curvature of the variable stiffness curved plate 3 in the variable stiffness guiding device is not zero, but along the direction of axis 1. increasing in the outward direction. This design can make the stiffness of the support increase non-linearly with the increase of the vertical deformation when the isolation structure is subjected to a rare earthquake, that is, the greater the deformation, the faster the vertical stiffness of the support increases, so it can further ensure The support will not produce excessive deformation and shear failure.

[0044] The curvature of the variable stiffness curved panel 3 in the variable stiffness guiding device can be designed according to specific conditions.

[0045] Figure 7 It is a three-dimensional seismic isolation support formed in series with the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com