Air/fuel ratio oxygen sensor performance measuring system

A technology of oxygen sensor and test system, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of inconvenient, accurate and comprehensive evaluation of oxygen sensor performance, high price, complex structure, etc., and achieve overcoming the congestion effect and stabilizing The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

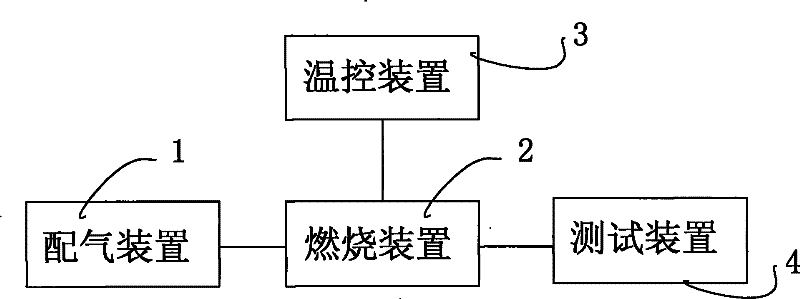

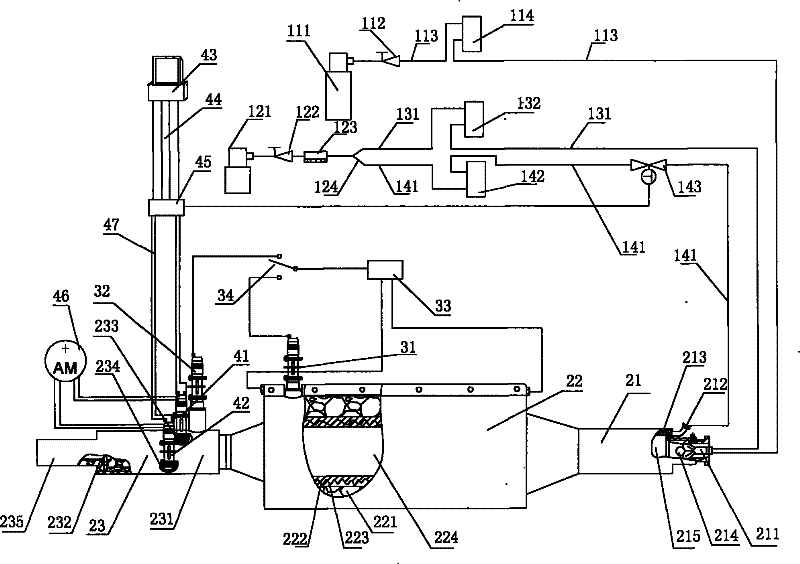

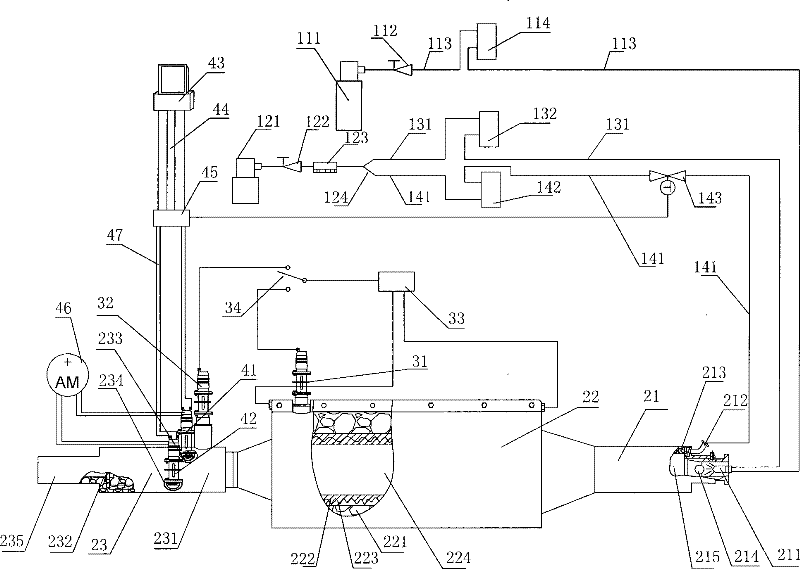

[0022] Embodiment: air-fuel ratio oxygen sensor performance testing system, including gas distribution device 1, combustion device 2, temperature control device 3 and testing device 4, wherein: the combustion device has a heating furnace 22; one end of the heating furnace 22 is connected with a combustion chamber 21; The other end of the heating furnace 22 is connected with a measuring chamber 23; the measuring chamber 23 is connected with a test device capable of measuring the oxygen concentration in the combustion device; the measuring chamber 23 is connected with a temperature control device 3 capable of measuring and controlling the temperature of the inner chamber of the heating furnace 22 ; The intake end of the combustion chamber 21 is connected with the gas distribution device 1 .

[0023] The inner surface of the side wall of the heating furnace 22 is provided with a thermal insulation layer 221; the inner side of the thermal insulation layer 221 is provided with a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com