DC pulse type bielectrode microminiature grinding and polishing tool

A DC pulse and polishing tool technology, which is applied in portable grinding beds, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of high difficulty and low safety, and achieve the effect of improving microscopic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

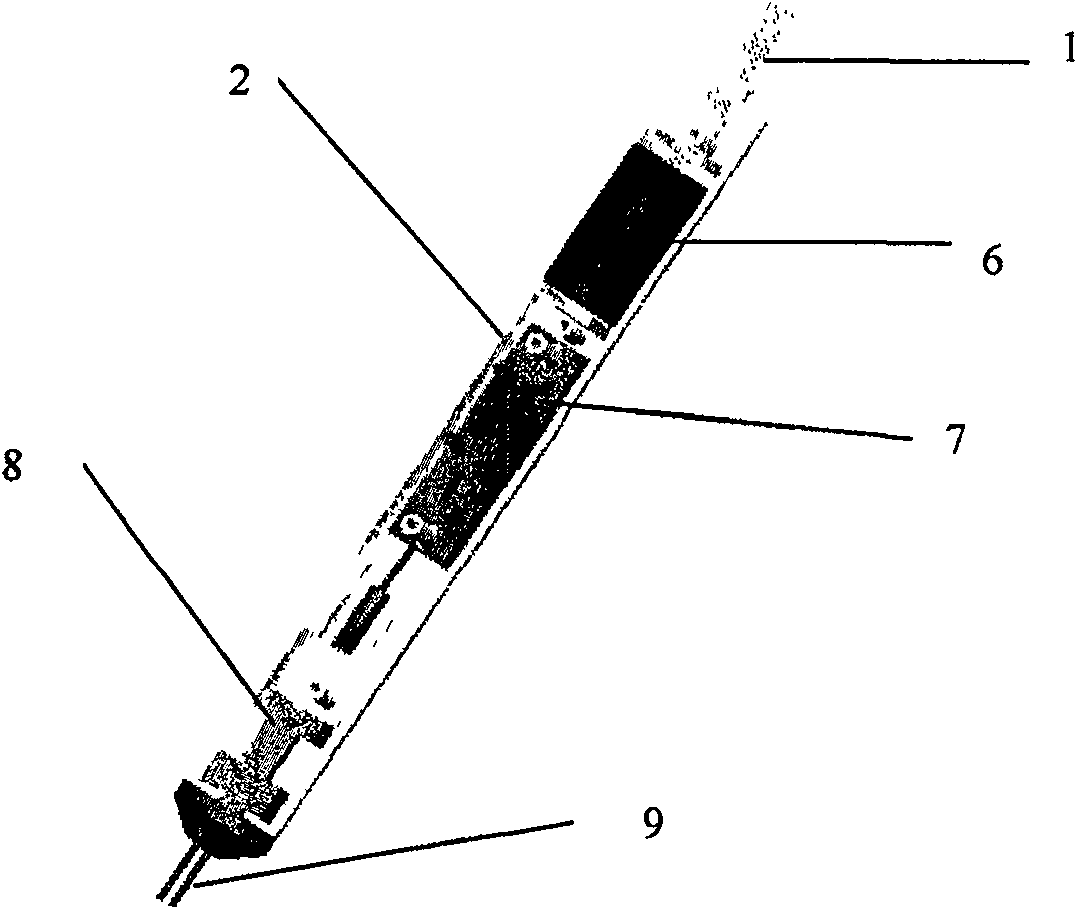

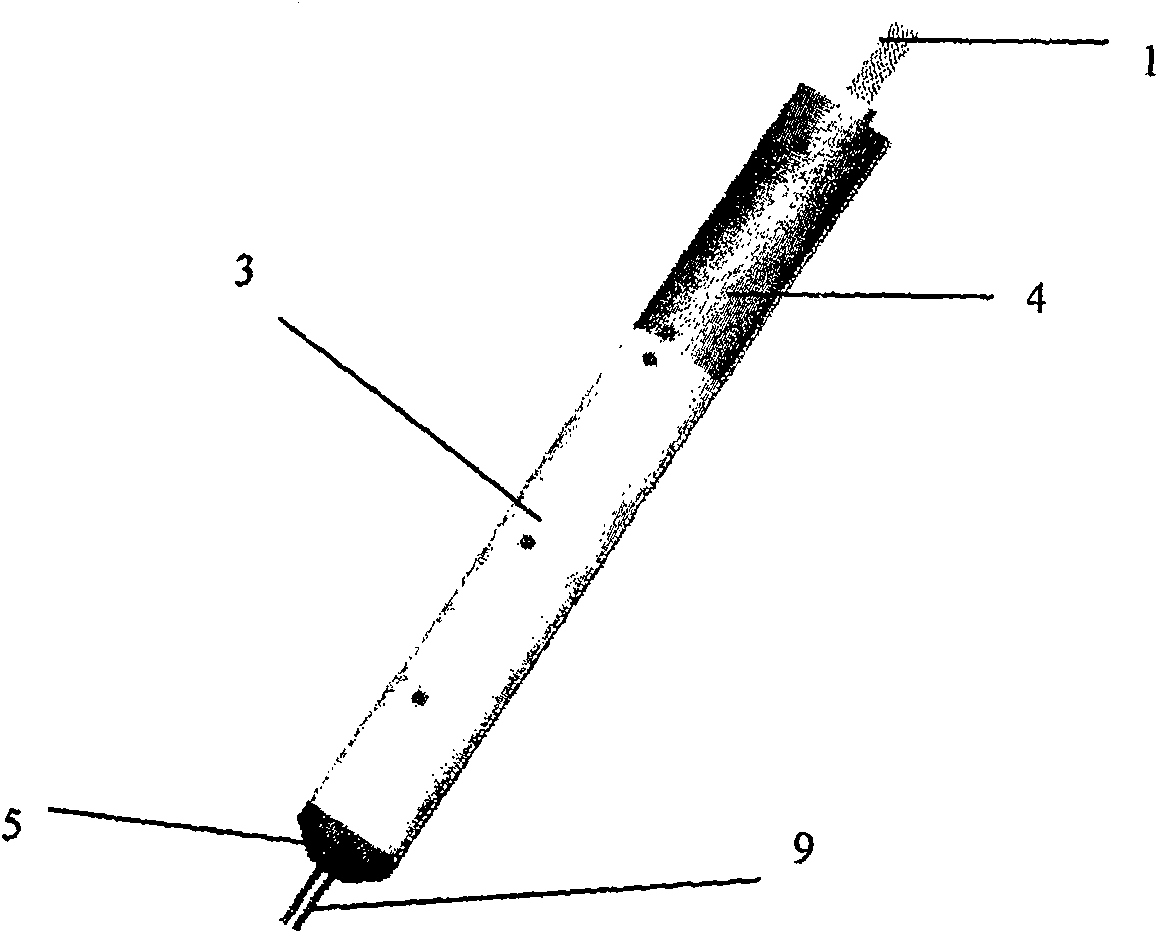

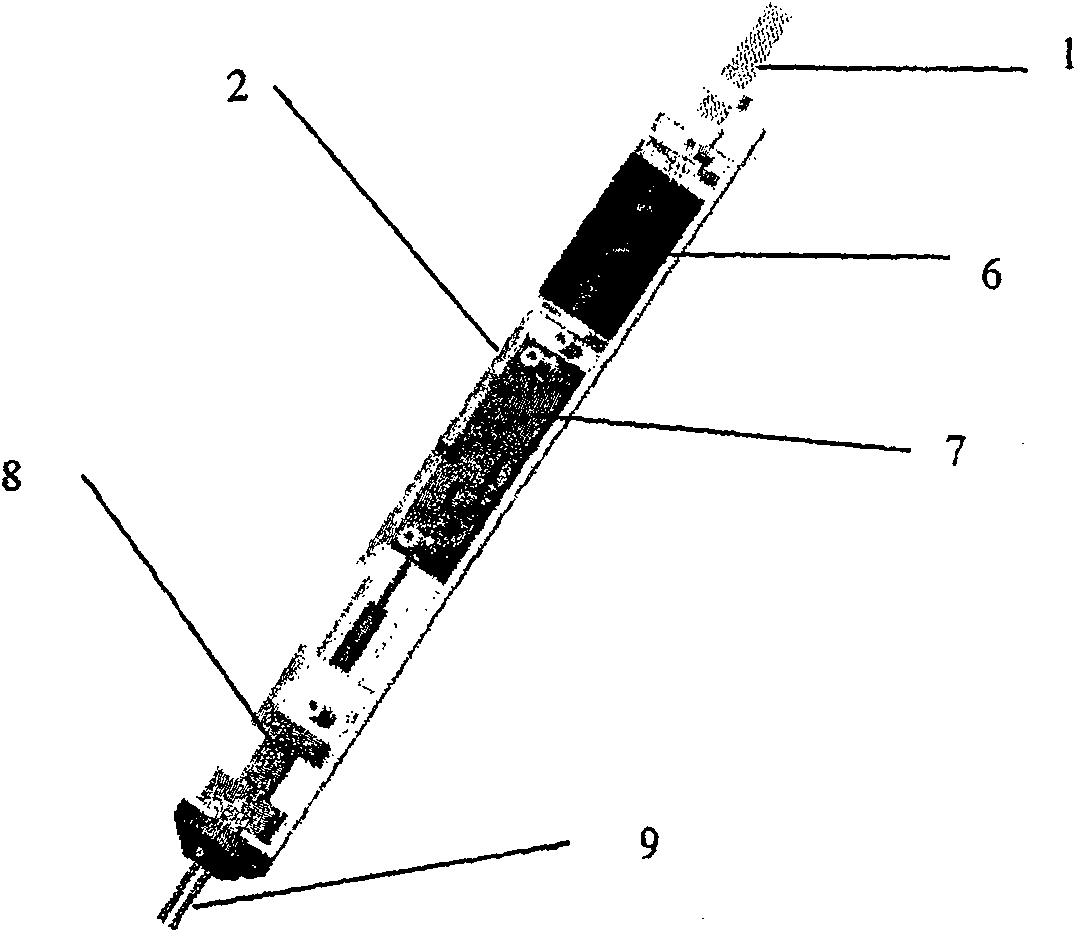

[0021] The present invention proposes a probe-shaped pulse electrorheological effect trace grinding tool as shown in Figure 1 and Figure 2, the bottom cover (2), upper cover (3), battery cover (4), tapered sleeve (5 ) are connected by nuts to form a cylindrical conical shell, and the electrode splint (8) is fixed inside the conical head end of the cylindrical conical shell by nuts, and one end of the electrode splint (8) holds two needle-shaped electrodes (9) And pass through the cone end of the cylindrical cone-shaped housing, the other end is connected with the circuit board (7), the other end of the circuit board (7) is connected to the battery (6), the electrode splint (8), the circuit board (7), The batteries (6) are all inside the cylindrical cone-shaped housing, and the electrode splint (8) and the circuit board (7) are fixed on the bottom cover (2) and the upper cover (3) by nuts, and the top nut (1) It is fixed on the top of one end of the cylindrical conical shell ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com