Probe-shaped electrorheological polishing tool

A polishing tool, electrorheological technology, applied in the direction of manufacturing tools, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of difficult tool design, difficult electrorheological effect, low safety, etc., to improve the microscopic quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

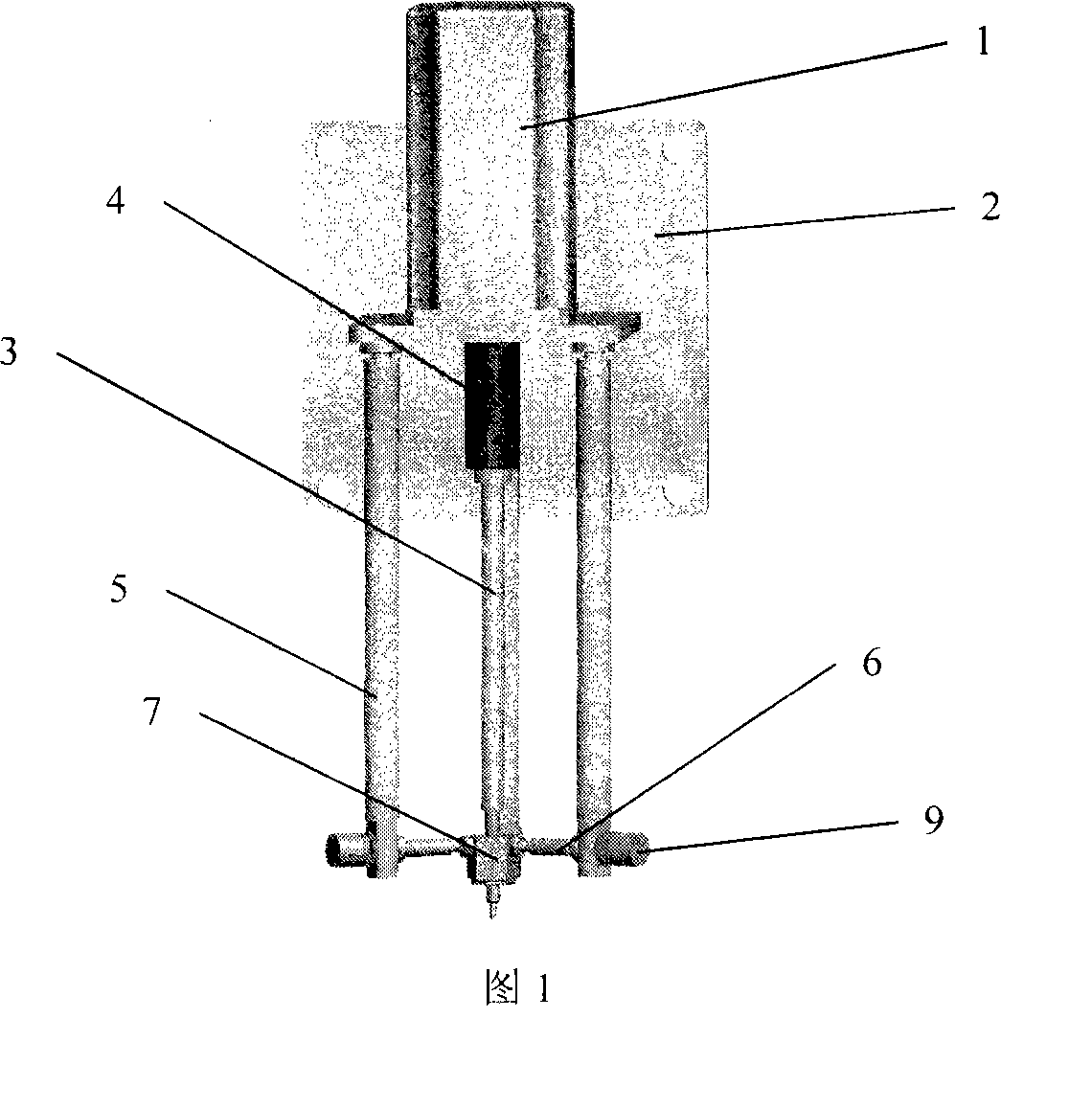

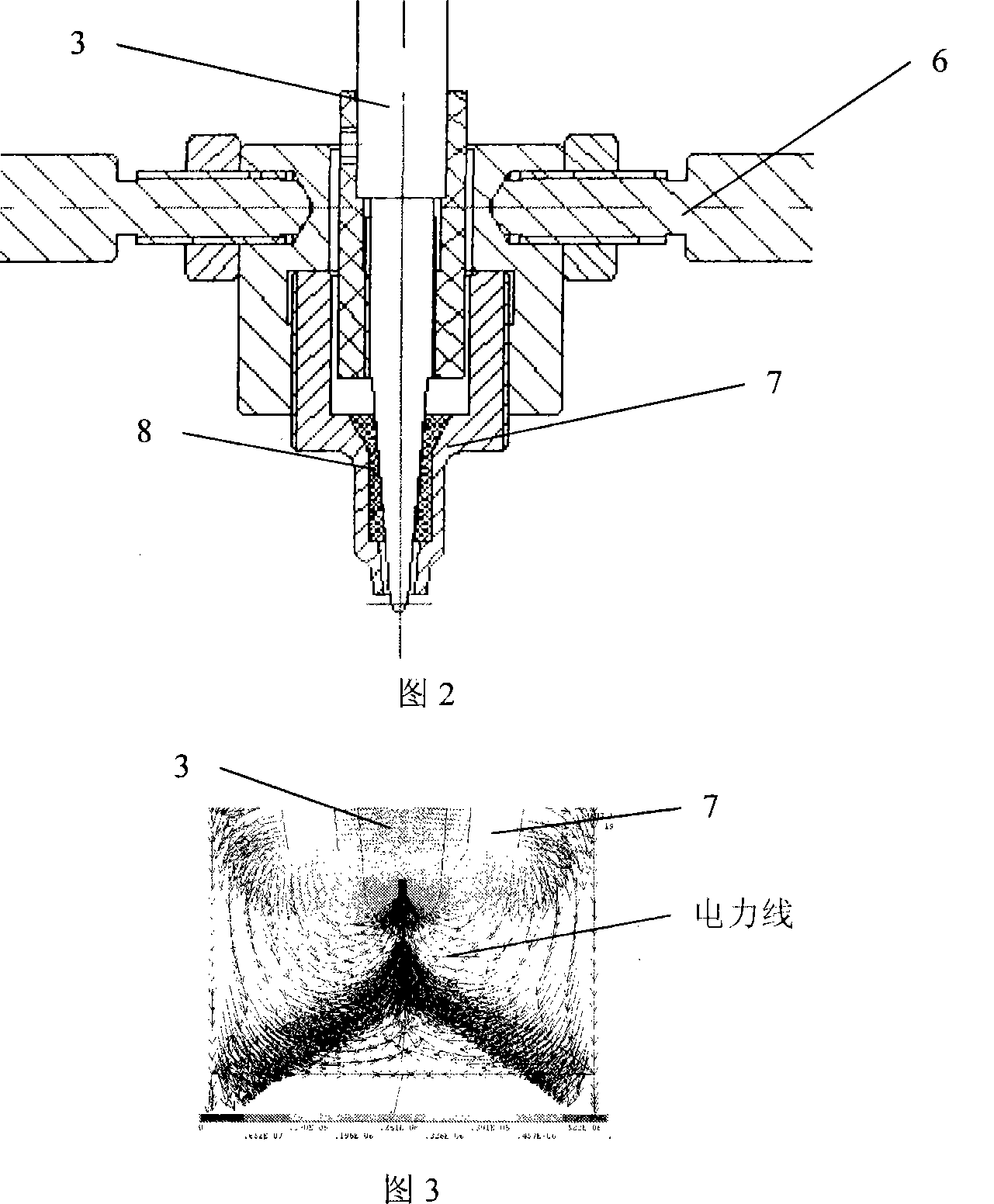

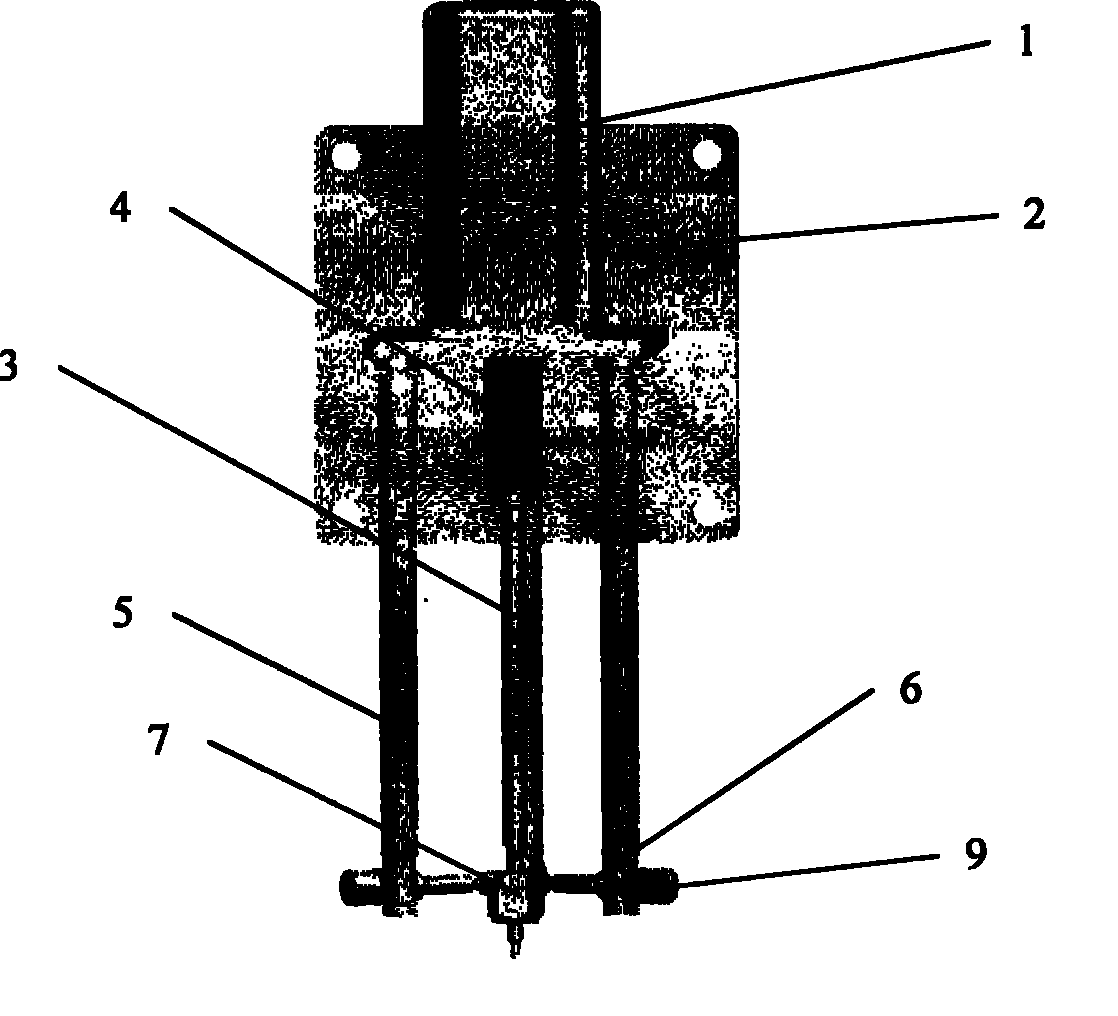

[0021] The probe-shaped electrorheological polishing tool of the present invention is such as figure 1 with figure 2 As shown, the motor 1 is installed on the integral support 2 through a positioning slot and a nut; the central shaft 3 and the motor 1 are connected through a coupling 4, and the central shaft 3 is grounded as a cathode; the three support rods 5 are evenly spaced according to the triangle Distributed and fixed with the integral bracket 2 by threads; the three terminal posts 6 are evenly distributed according to the plane triangle, respectively corresponding to the positions of the lower end through holes of the three support rods 5 and are connected to the taper sleeve 7 through the through holes; the taper sleeve 7 is opened in the center The through hole is connected to the anode of the power supply through the terminal 6; the central shaft 3 passes through the central through hole of the tapered sleeve 7 and forms a probe-shaped protruding end vertically; the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com