Feeding device of sewing machine

A technology of feeding device and sewing machine, which is applied in the direction of control device for sewing machine, sewing machine components, sewing equipment, etc., can solve the problem of inability to properly feed the cloth, and achieve the effect of reducing vibration or noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, an embodiment of the sewing machine feed device according to the present invention will be described in detail.

[0026]

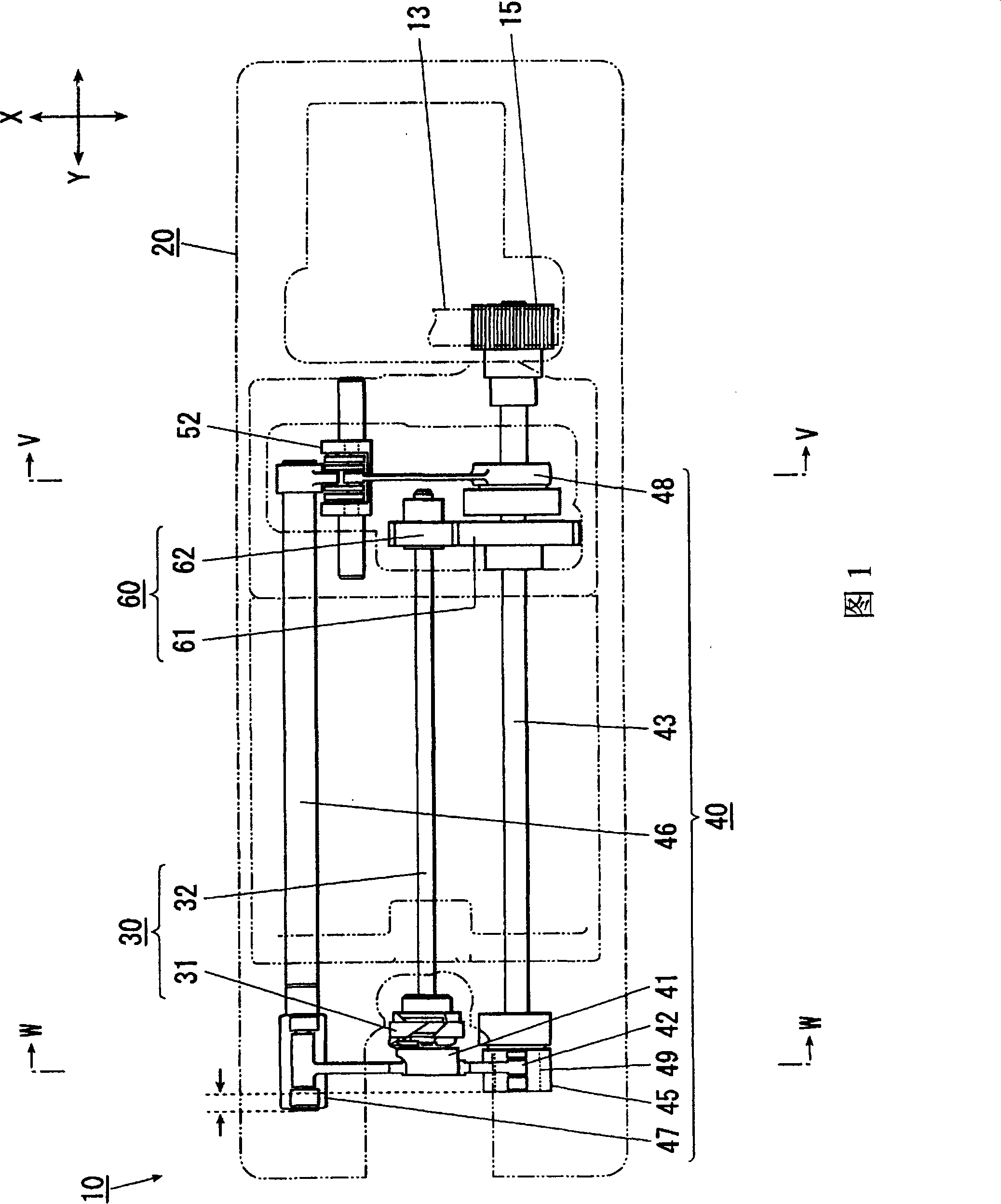

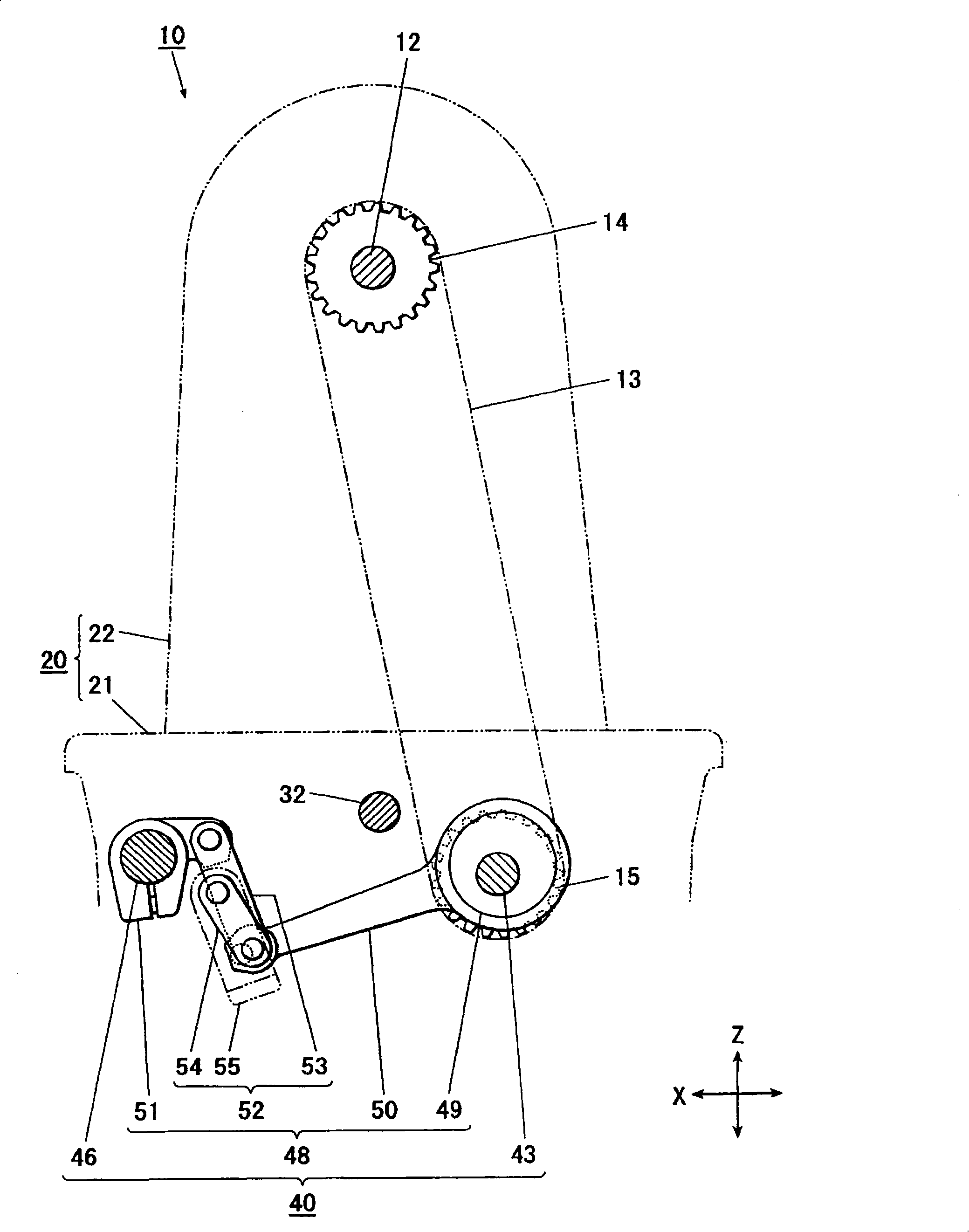

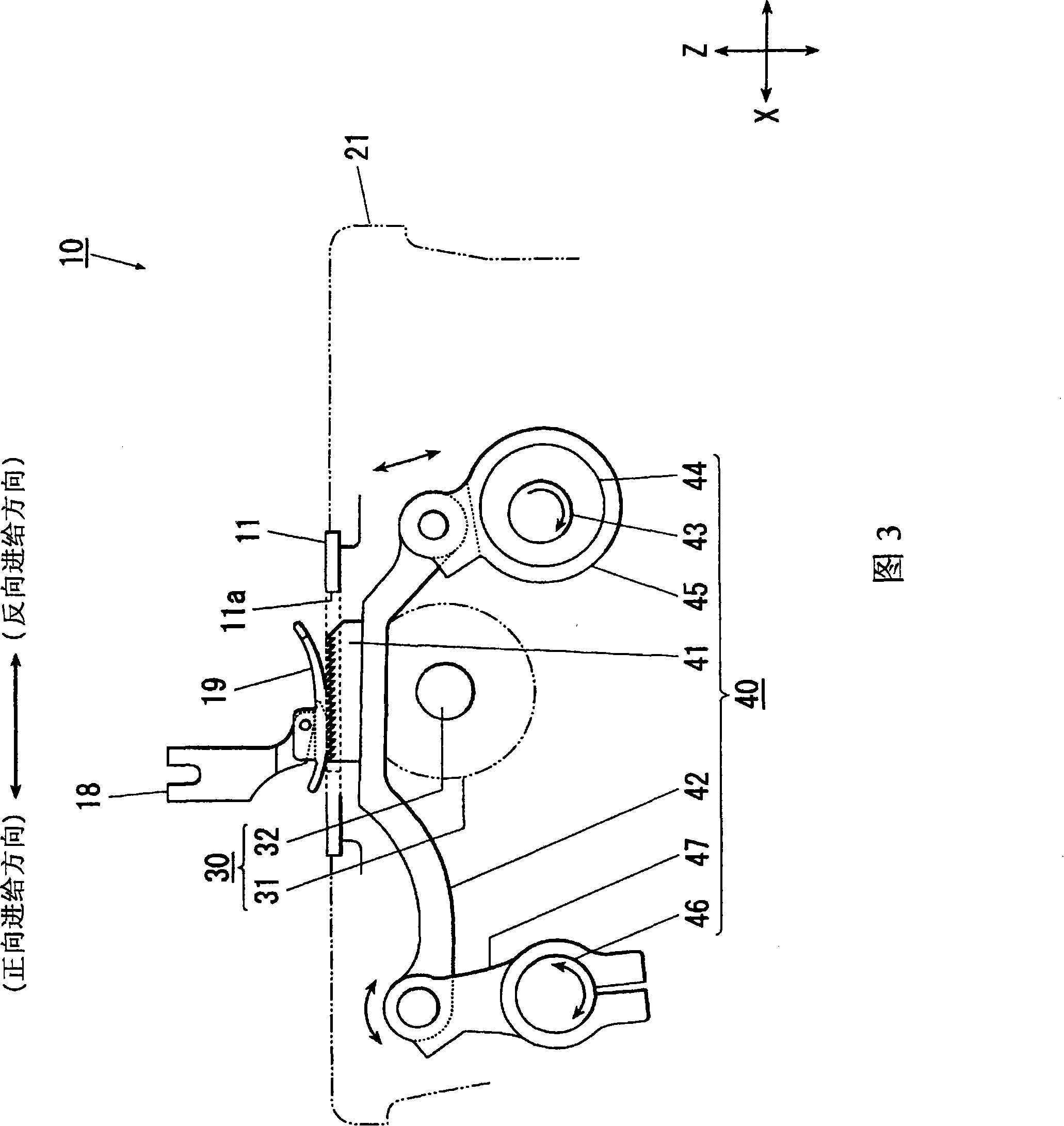

[0027] Such as Figure 1 to Figure 4 As shown, the sewing machine 10 has: an unillustrated sewing machine motor; an unillustrated up and down movement mechanism, which moves the sewing needle up and down; At the same time, it forms flat seam stitches together with the aforementioned sewing needles; the feeding device 40, which feeds the cloth; the gear mechanism 60, which transmits the rotational driving force from the upper and lower feed shafts 43 of the feeding device 40 to the kettle mechanism 30; the cloth A presser foot 19 which presses the cloth above the needle plate 11 from above; and a main body frame 20 which supports each of the above structures.

[0028] (main frame)

[0029] The main body frame 20 has: a base portion 21 having the needle plate 11; an arm portion (not shown) facing above the base portion 21 and having the afor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com