Torque limiter

A technology of torque limiter and rotation, which is applied in the direction of object separation, pile separation, thin material processing, etc., and can solve the problem of large-scale outer wheel body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

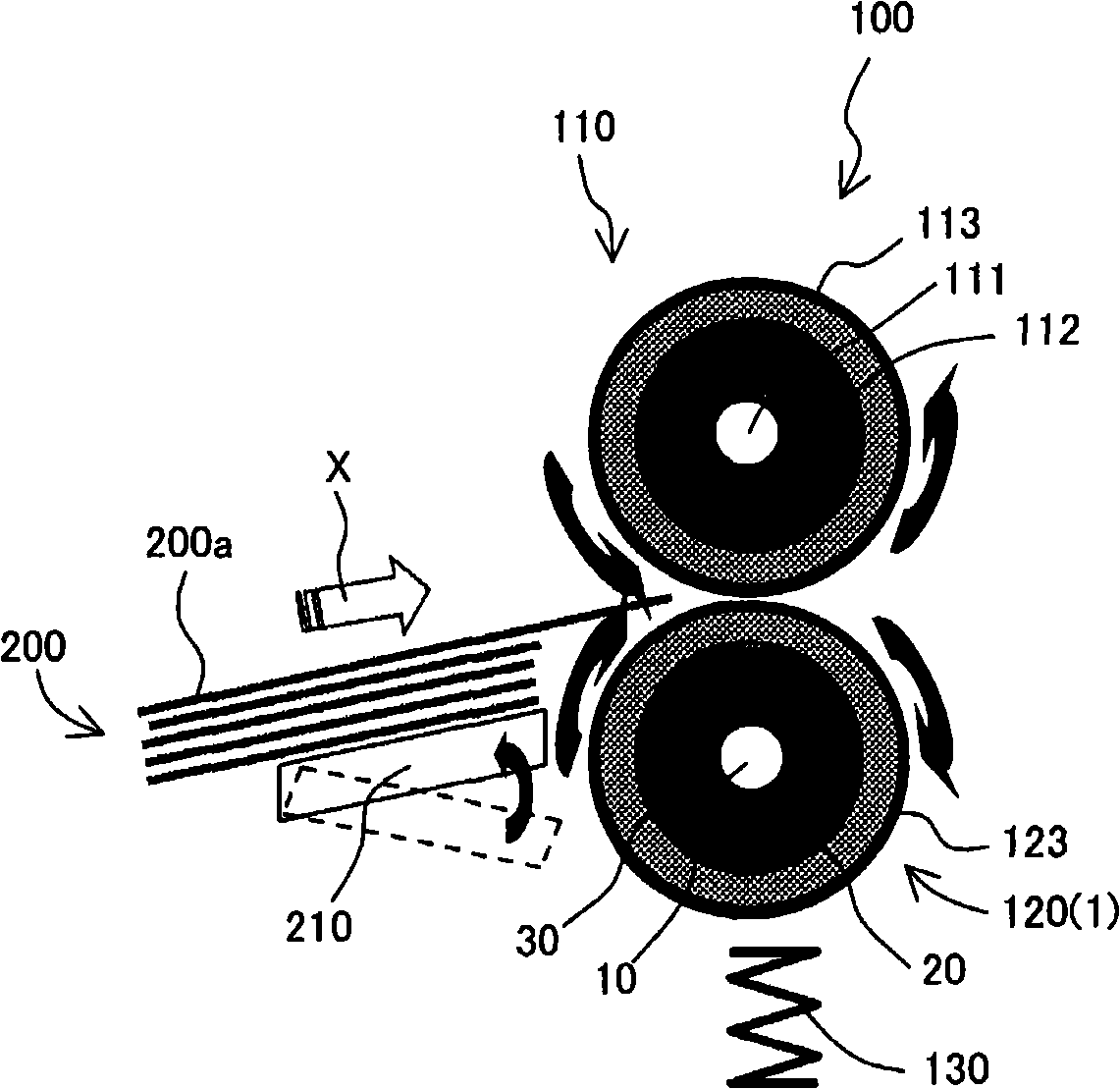

[0040] Preferred embodiments of the torque limiter of the present invention will be described below with reference to the drawings.

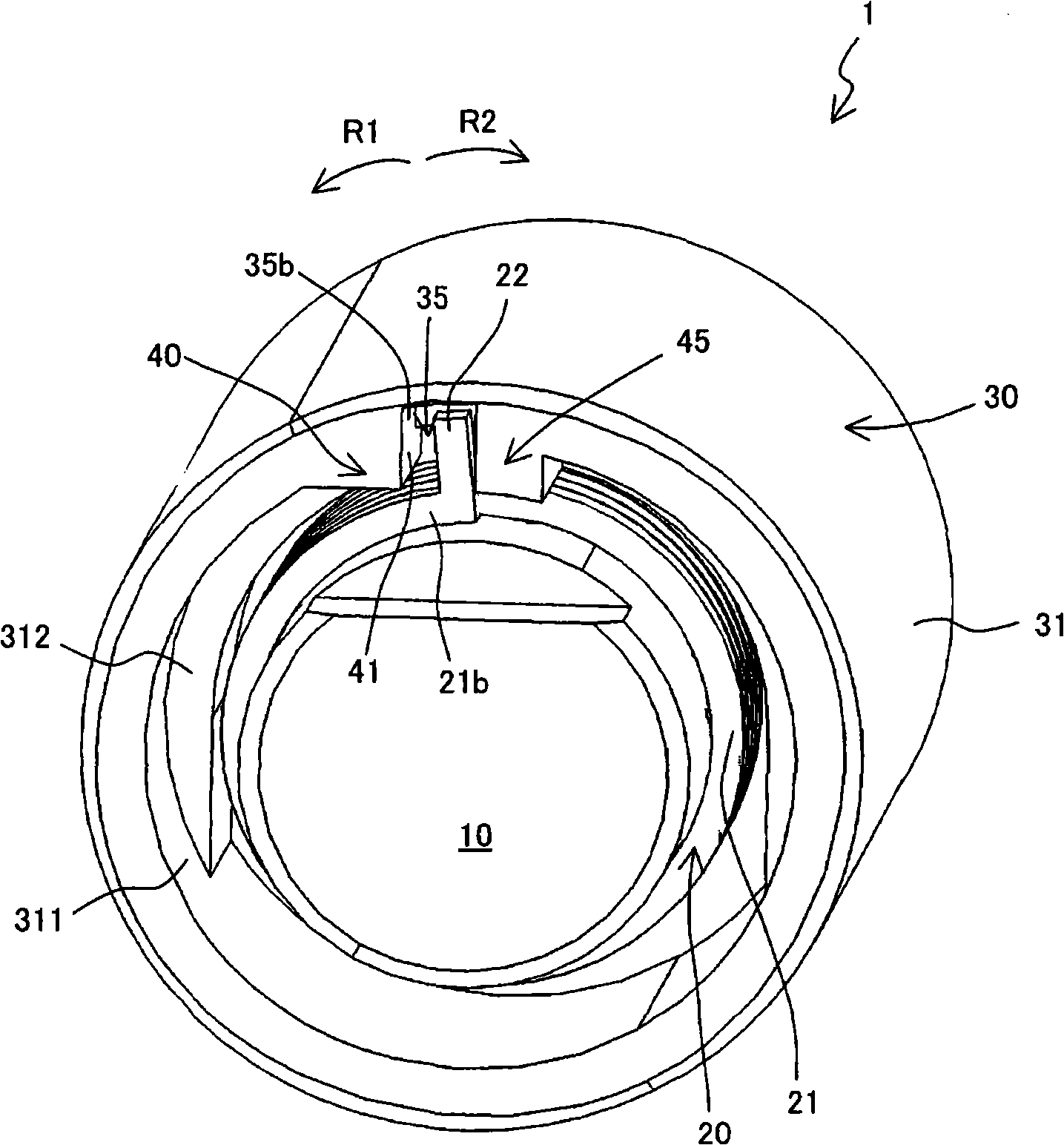

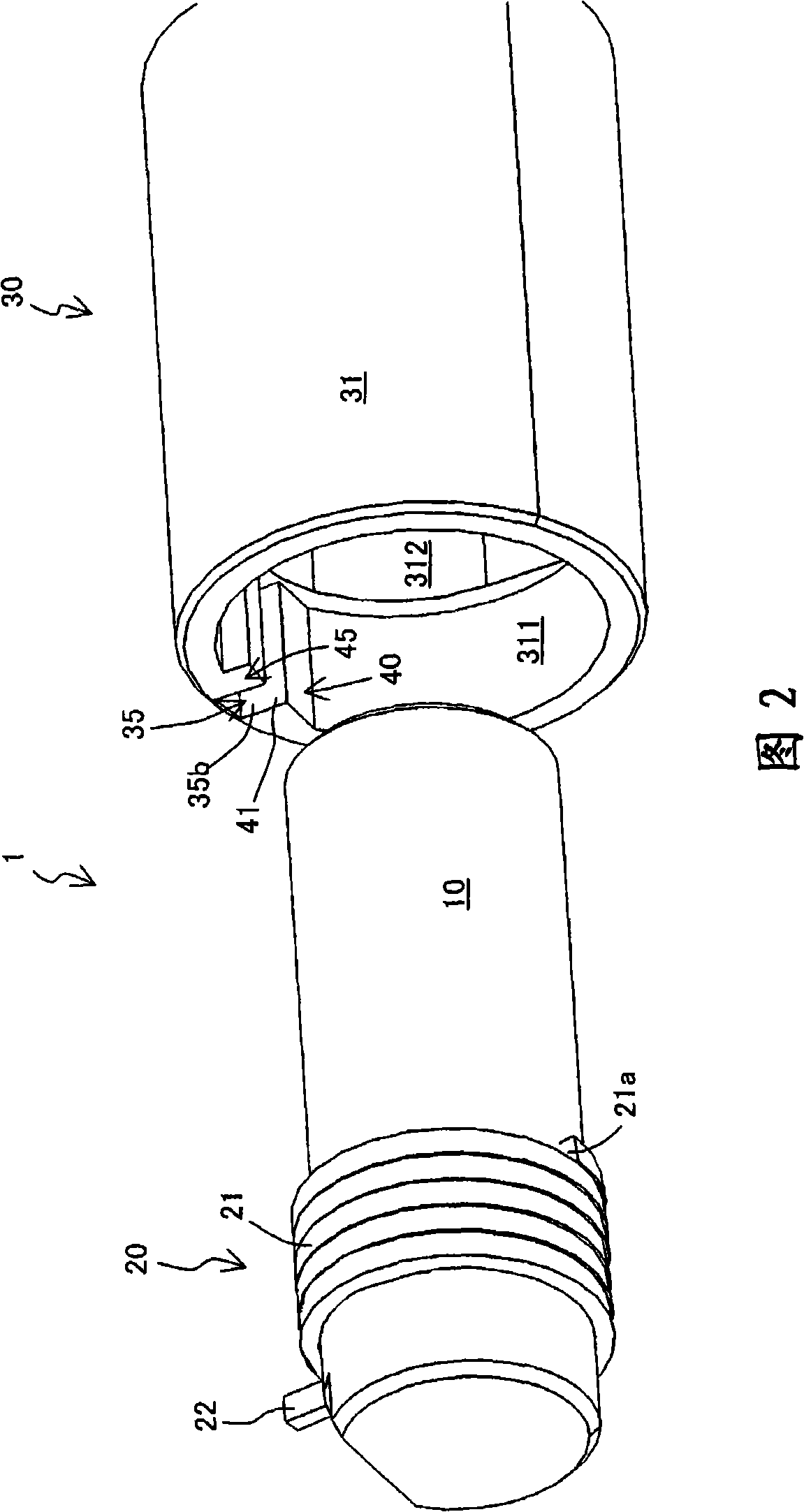

[0041] figure 1 2 and 2 respectively show a perspective view and an exploded perspective view of the torque limiter 1 of this embodiment.

[0042] like figure 1 As shown in FIG. 2, the above-mentioned torque limiter 1 has an inner ring body 10, a coil spring 20 wound on the above-mentioned inner ring body 10, and an inner ring body in a state where the above-mentioned coil spring 20 is wound is inserted. The hollow outer wheel body 30 of 10.

[0043] As shown in FIG. 2, the above-mentioned coil spring 20 has a winding portion 21 wound on the outer peripheral surface of the inner ring body 10, and a winding end portion 21b from the above-mentioned winding portion 21 (refer to figure 1 ) The hook portion 22 extending radially outward with the axis of the inner ring body 10 as a reference.

[0044]On the inner peripheral surface of the peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com