Active type loose warp adjusting apparatus

An adjusting device and warp loosening technology, applied in textile, textile and papermaking, looms and other directions, can solve the problems of affecting the accuracy of warp tension, increasing the movement resistance of the mechanism, affecting the follow-up performance, etc. Accurate effect of impact, large load and tension detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

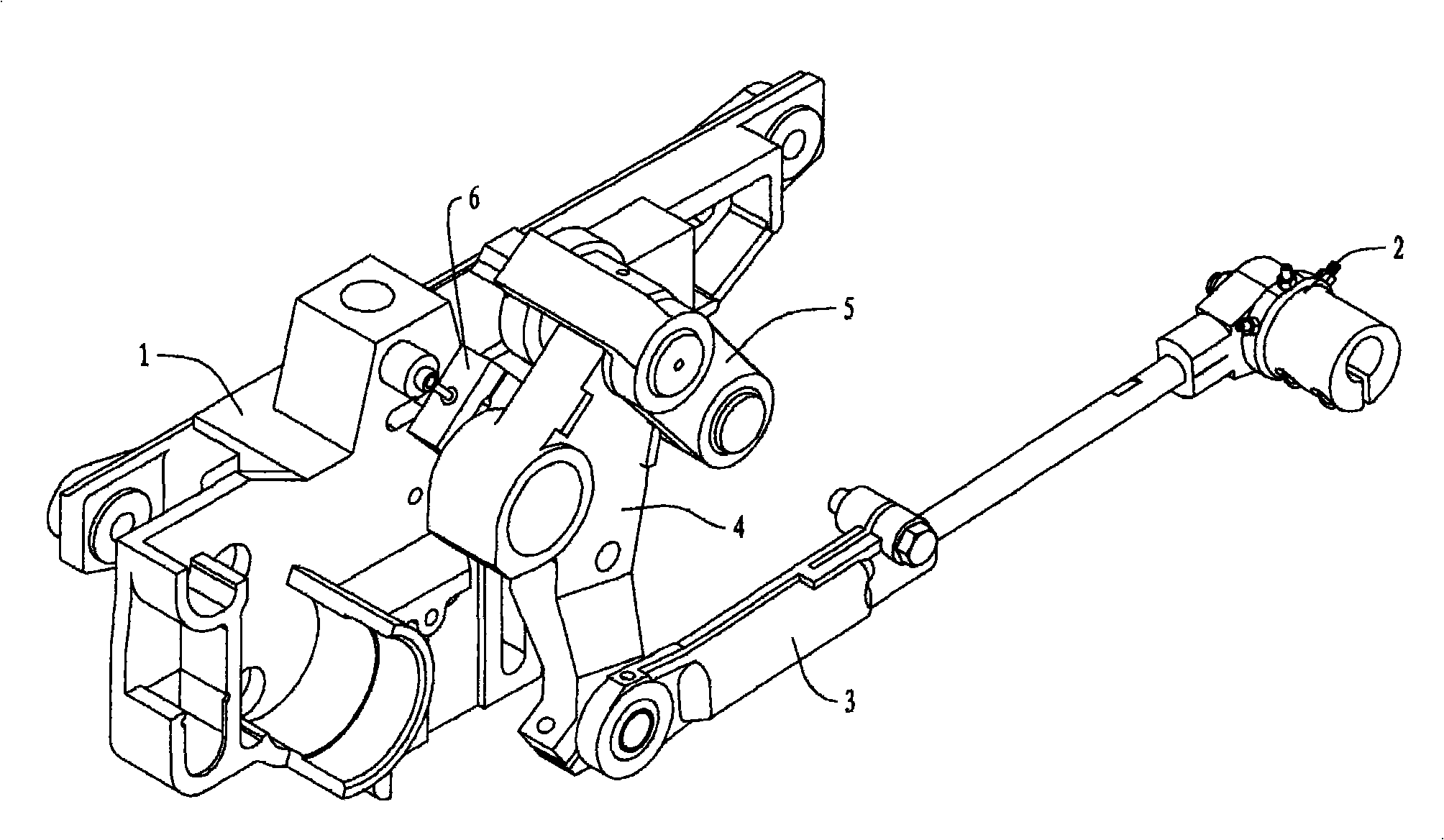

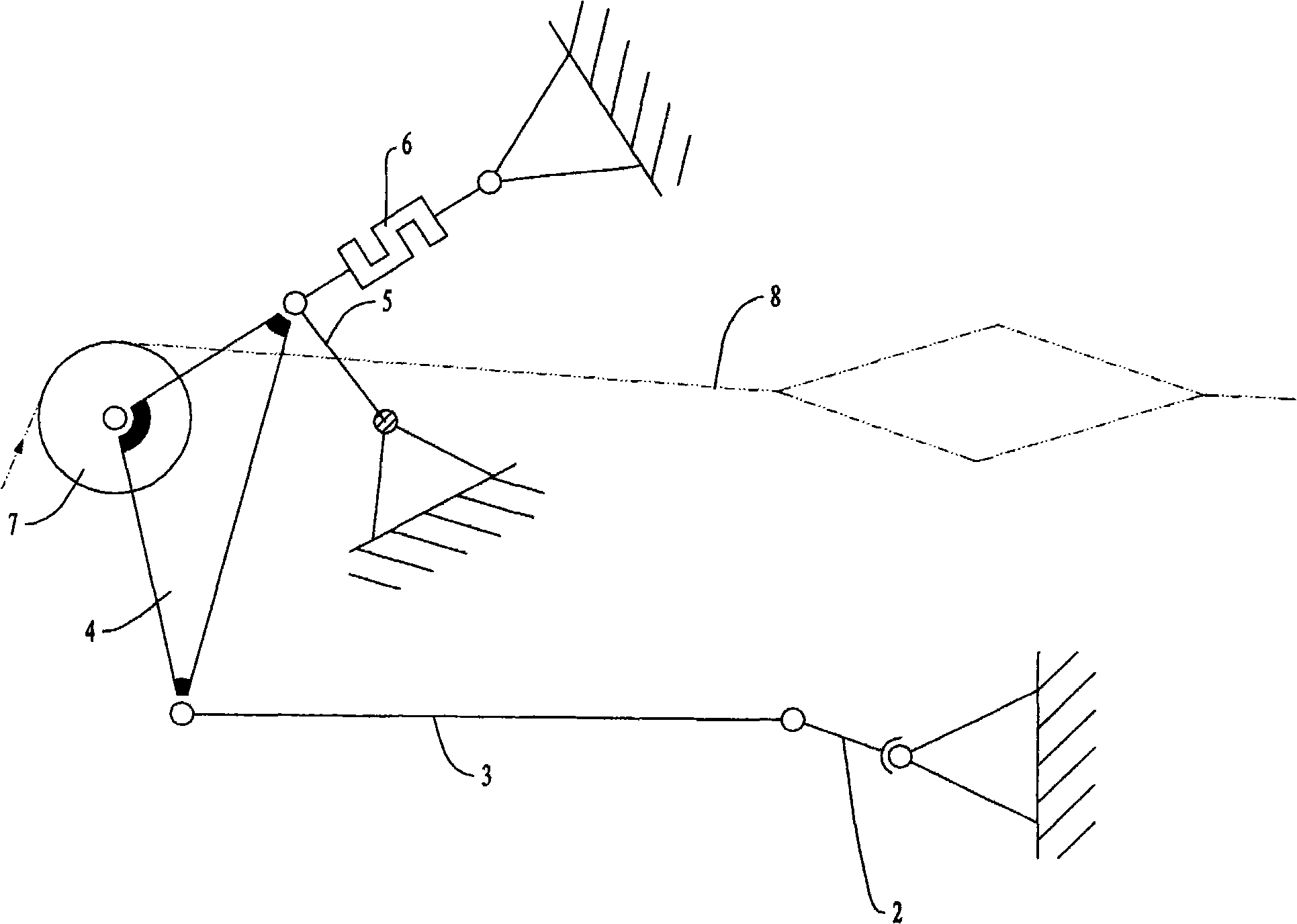

[0013] Such as figure 1 As shown, the positive warp loosening adjustment device includes the eccentric adjustment device 2 provided on the loom body 1 and the warp loosening rocker 4 for installing the tension roller 7. Through the adjustment device, the tension roller 7 is installed between the loose warp rockers 4 of the two loose warp adjustment devices. Between one end of the loose warp rocker 4 and the eccentric adjustment device 2, a loose warp adjustment rod device 3 is connected, and a rocker bracket 5 is hinged at the other end of the loose warp rocker 4, and the rocker bracket 5 is fixed to the body 1. connection; a tension sensor 6 is provided between the rocker bracket 5 and the body 1, wherein the rocker bracket 5 can be fixedly connected to the body 1 through a bushing and a pin shaft at one end, which is convenient to use, and the other end of the rocker bracket 5 It is hingedly connected with the warp loosening rocker 4 , and a tension sensor 6 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com