Novel heat transfer temperature field and solid-state furnace slag propelling system

A technology of propulsion system and temperature field, applied in lighting and heating equipment, etc., can solve the problems of reduced friction coefficient, low product operating cost, low cost, etc., and achieve the effect of reduced friction coefficient, low operating cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

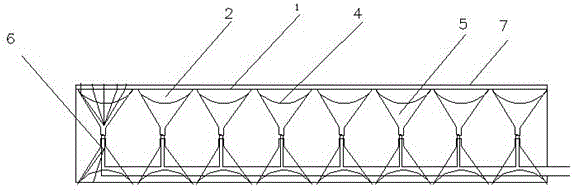

[0018] Embodiment 1 A new type of heat transfer temperature field and solid slag propulsion system, including a base 1, a boss 2 placed on the base 1, one side of the boss 2 is a curved surface 3, and the other side is a plane 4, the curved surface faces downward, and the convex The convex surface of platform 2 is provided with a warm output interface 5, which is a funnel-shaped mirror structure. 1 is provided with a sun tracker, and there are several bosses 2.

Embodiment 2

[0019] Example 2 as figure 1 As shown, it is improved on the basis of Example 1. Its thermal characteristic technology is computer finite element three-dimensional analysis method. Under the design size matched by equipment, it can ensure that the deviation of radial water flow is less than 8.9%, and the fluctuation rate of longitudinal temperature gradient Less than 4.3%. The structural combination design of the equipment adopts the building block design principle to fully heat the water and slag.

Embodiment 3

[0020] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1. Its warm output interface 5 is provided with a screen bottom inside, and the bottom of the screen is a vibrating screen device. It is composed of screen, upper screen, connecting pipe and vibrating motor. There is a brush on the vibrating screen body that can be cleaned circularly. The upper screen and the lower screen are cleaned by this brush. When the vibrating screen is working, The fine particles in the wet sand and gravel material accumulate on the screen, and are brushed and swept by the brush to prevent the pores of the screen from being blocked, so that the vibrating screen can work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com