Surface shape calibrating method of spherical surface sun heliostat

A calibration method and heliostat technology, applied in the testing, measuring devices, instruments, etc. of machines/structural components, can solve problems such as heavy workload, and achieve the effect of an efficient calibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] Embodiment of the present invention is 64m 2 The spherical heliostat, the spherical radius R is 600m, and the artificial light source is a xenon lamp with a light exit diameter of 150mm.

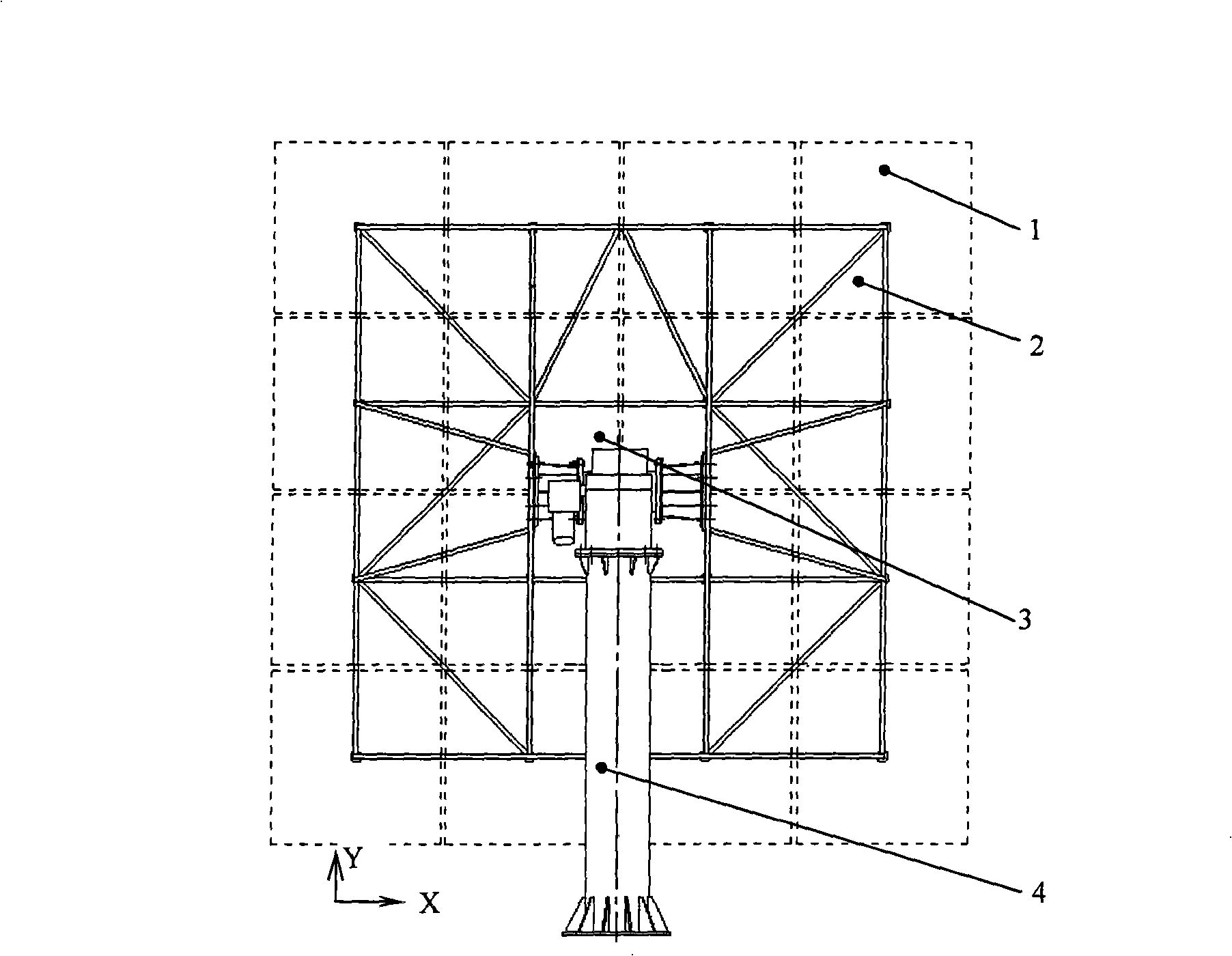

[0035] The structure of the heliostat is as figure 1 As shown, the heliostat includes a reflector, a support frame 2 , a transmission system 3 and a tracking control system, and the transmission system 3 connects the support frame 2 and the column 4 . The transmission system 3 realizes fixed-day tracking through the horizontal-tilt dual-axis rotation tracking method. The overall reflection surface of the heliostat is a spherical surface, and the actual reflection surface shape is composed of 16 spherical sub-mirrors 1 of 2m×2m. Each sub-mirror 1 has the same surface shape as the overall spherical surface. Each sub-mirror passes through a single-poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com