Electric cleaner

A vacuum cleaner and electric technology, which is applied in the direction of vacuum cleaners, suction filters, cleaning filter devices, etc., can solve the problems of low suction power, insufficient centrifugal separation of dust, and enlarged curved suction path, etc., to achieve high suction power, Excellent air volume maintenance performance and the effect of ensuring air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

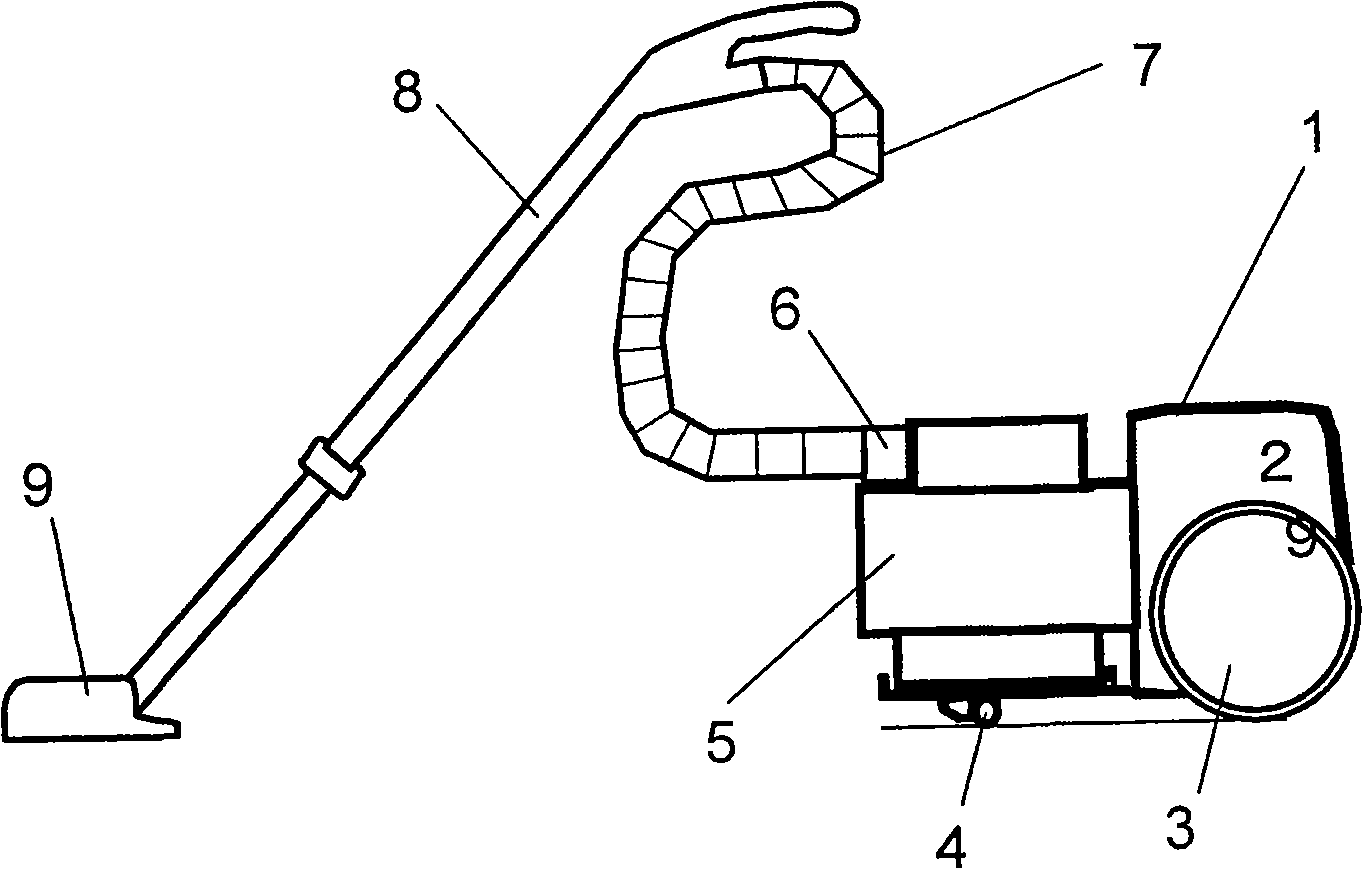

[0147] 1 and 2 show an electric vacuum cleaner according to Embodiment 1 of the present invention.

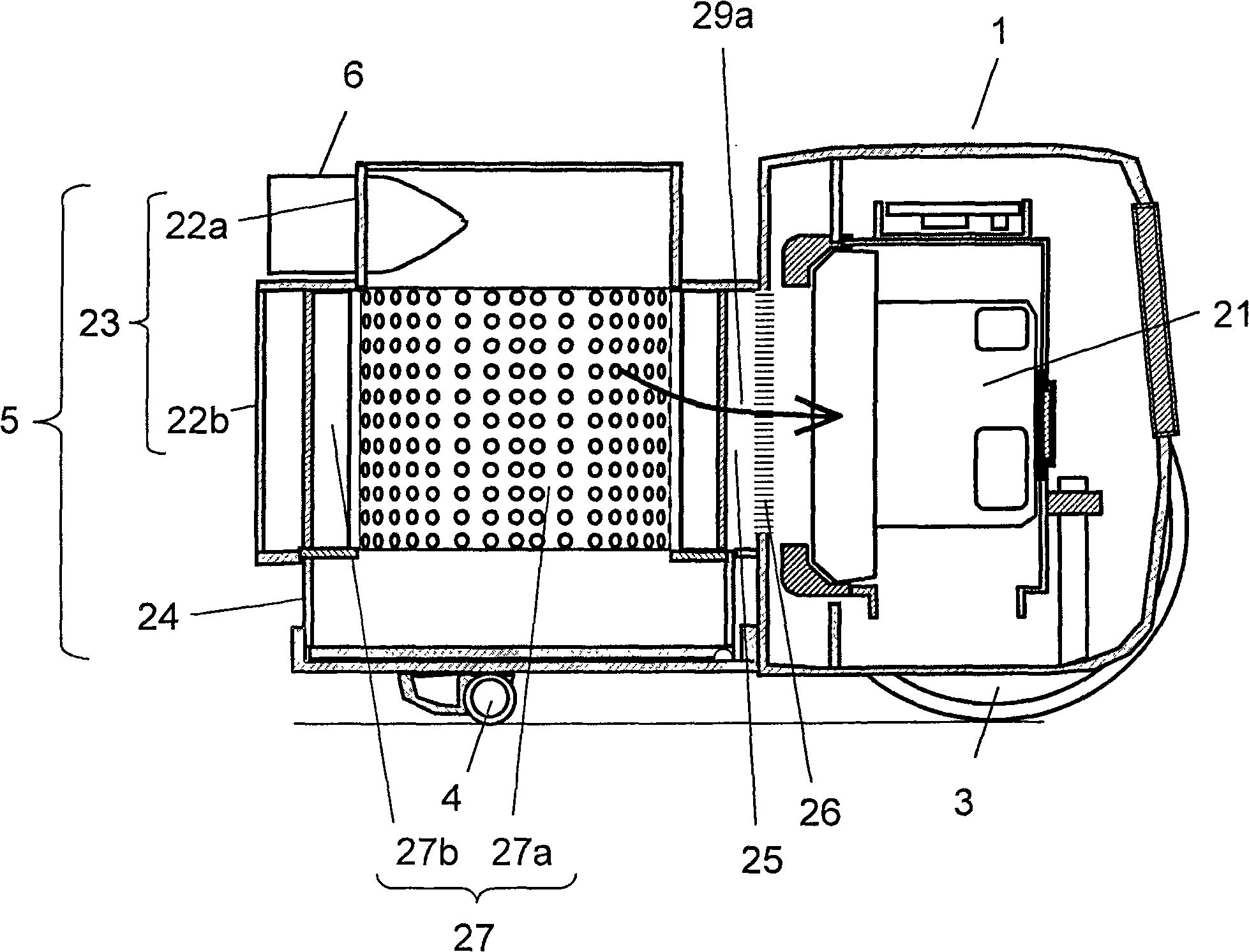

[0148] As shown in FIG. 2 , the electric vacuum cleaner main body 1 is equipped with an electric blower 21 that generates suction airflow. In addition, wheels 3 and casters 4 are installed outside the electric vacuum cleaner main body 1 to move freely on the ground. Furthermore, on the upstream side of the electric blower 21, there is provided a dust collecting box 5 that can be freely attached to and detached from the main body 1 of the electric vacuum cleaner through a partition wall 26 having air permeability. Dusty air.

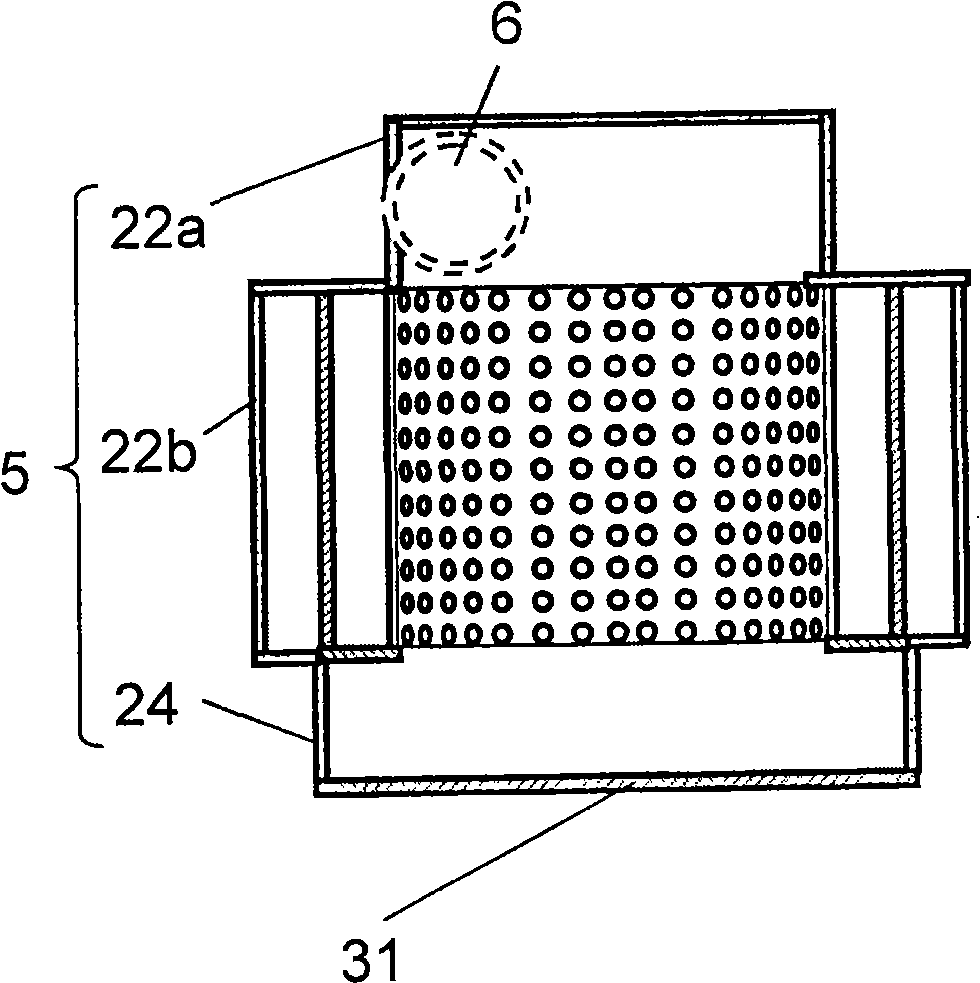

[0149] In addition, the dust collecting box 5 is composed of a plurality of hollow cylinders with different diameters connected into a multi-stage shape. In the first embodiment, it is a three-stage structure, and includes the box upper part 22a, the box central part 22b, and the dust collector in order from the upper stage. Storage section 24. The case ...

Embodiment approach 2

[0188] Next, Embodiment 2 of the present invention will be described. Hereinafter, differences in configuration and operation from Embodiment 1 will be mainly described, and elements that are the same as those in Embodiment 1 will be assigned the same reference numerals, and descriptions of the configuration and operation will be omitted.

[0189] 10 , 11A, 11B, 11C, and 11D are cross-sectional views showing the electric vacuum cleaner and dust collecting box 5 according to Embodiment 2. FIG.

[0190] As shown in Figures 10, 11A, 11B, 11C, and 11D, the difference from Embodiment 1 is that not only a cylindrical dust filter 27 is provided in the dust collecting box 5, but also a hollow disc-shaped third The dust removal filter 28 , the third dust removal filter 28 is provided below the cylindrical dust removal filter 27 .

[0191] This 3rd dust removal filter 28 is made of coarse dust filter, and the same as the first dust removal filter 21, is the metal screen cloth of 250 mi...

Embodiment approach 3

[0210] Next, Embodiment 3 of the present invention will be described. Hereinafter, differences in configuration and operation from Embodiments 1 and 2 will be mainly described, and the same elements will be assigned the same reference numerals, and descriptions of the configuration and operation will be omitted.

[0211] FIG. 14 is a cross-sectional view of a part of cylindrical dust filter 27 seen from above. About other structures, it is the same as Embodiment 2.

[0212] As shown in FIG. 14 , a drive gear 141 is provided on the sealing portion 43 of the upper outer periphery of the second dust filter 27 b constituting the cylindrical dust filter 27 , and the other drive gear 142 fitted with the drive gear 141 , and the rotating motor 143 that drives the drive gear 142 to rotate, the second dust removal filter 27b and the first dust removal filter 27b rotate integrally.

[0213] Again, in this way, both the first dust removal filter 27a and the second dust removal filter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com