Electric cleaner

A vacuum cleaner, electric technology, applied in the direction of vacuum cleaners, suction filters, household appliances, etc., can solve the problems of large vacuum cleaners, clogged meshes, difficult to small, etc., achieve high suction power, reduce ventilation resistance, prevent suction and air volume Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

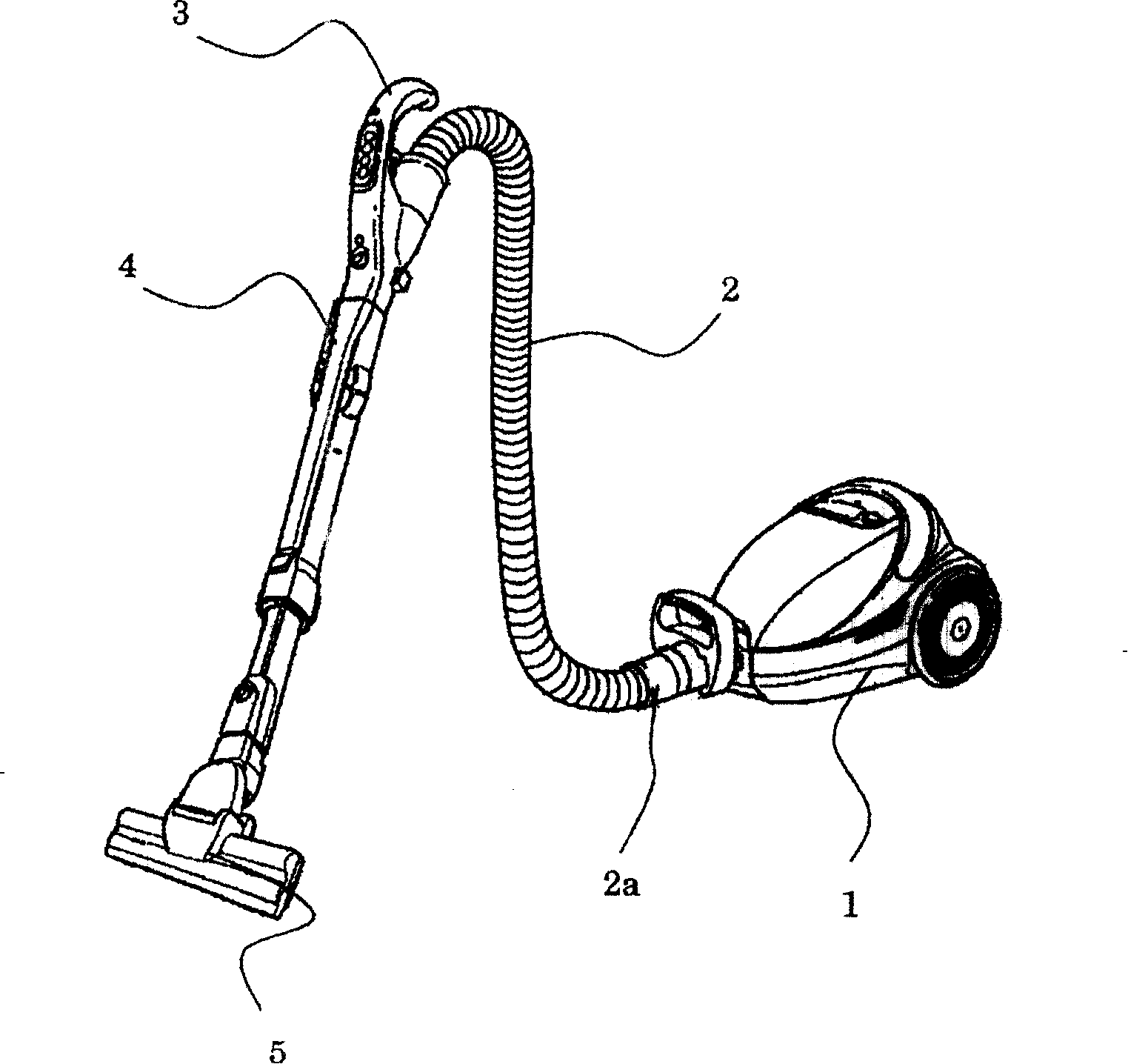

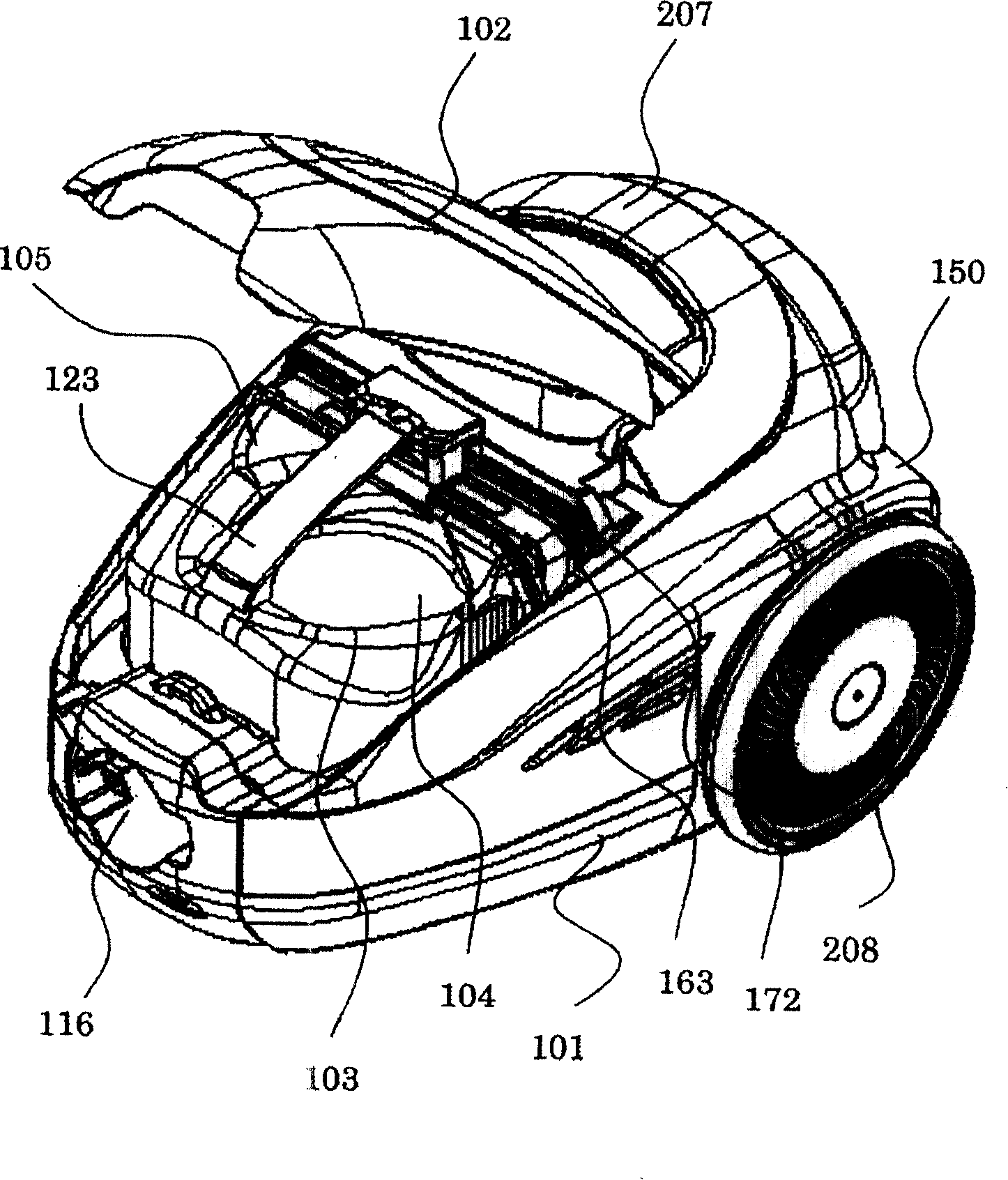

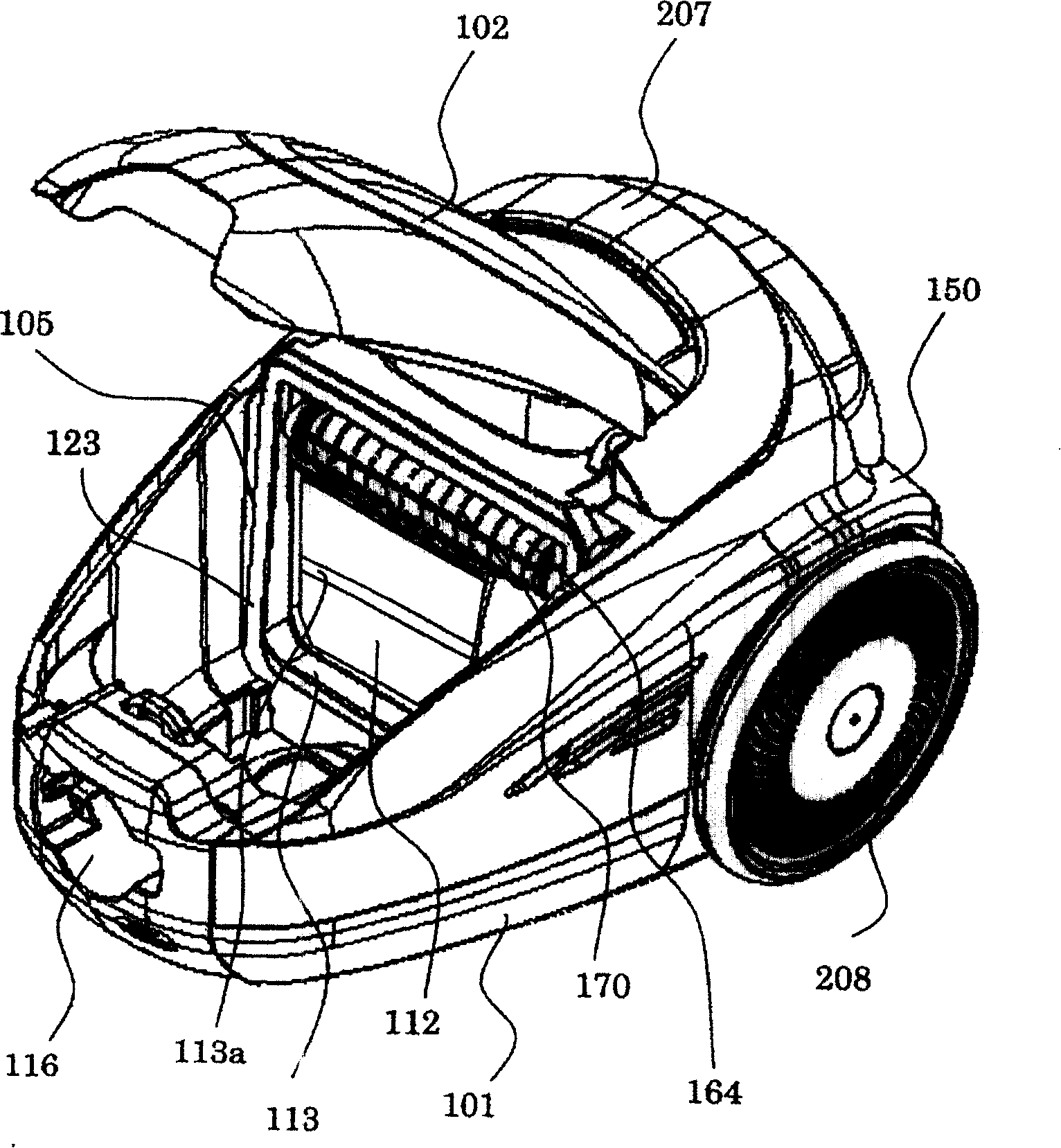

[0038] figure 1 It is a perspective view showing the appearance of an electric vacuum cleaner according to an embodiment of the present invention; figure 2 is a perspective view showing that the upper cover of the main body of the vacuum cleaner is in an open state; image 3 It is a perspective view showing the state where the dust collecting part 103 is detached by opening the upper cover of the main body of the vacuum cleaner; Figure 4 is a schematic diagram showing the air flow in the main body of the vacuum cleaner; Figure 5 is a three-dimensional view of the appearance of the dust collection part 103; Figure 6 is an external perspective view of the dust collection part 103 seen from the downstream side; Figure 7 It is an appearance perspective view after opening the filter frame 140 and the filter frame 163 together from the dust collecting case 105; Figure 8 is a longitudinal sectional view of the dust collection part 103 including the central axis of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com